Silicon carbide (SiC) epitaxy

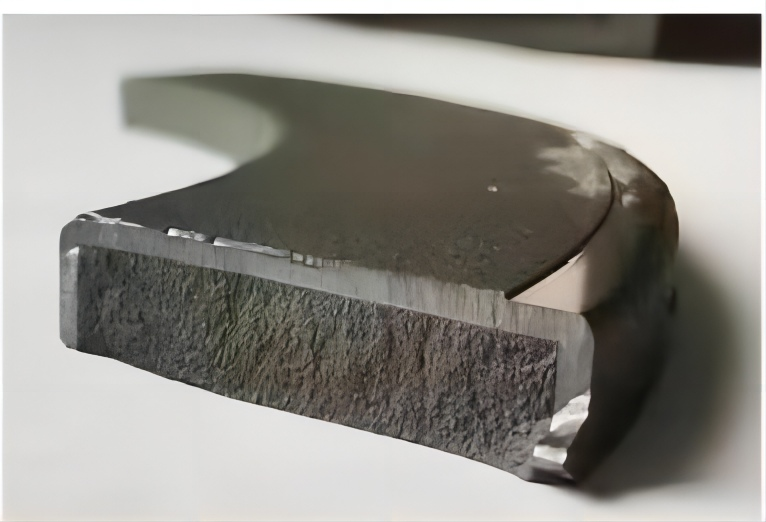

Lub tais epitaxial, uas tuav lub SiC substrate rau loj hlob SiC epitaxial daim, muab tso rau hauv cov tshuaj tiv thaiv chamber thiab ncaj qha hu rau lub wafer.

Sab sauv ib nrab hli yog cov nqa khoom rau lwm cov khoom siv ntawm cov tshuaj tiv thaiv chamber ntawm Sic epitaxy cov cuab yeej, thaum lub hli qis ib nrab hli txuas nrog lub raj quartz, qhia cov roj los tsav lub hauv paus susceptor tig. lawv yog kub-tswj thiab ntsia rau hauv cov tshuaj tiv thaiv chamber yam tsis muaj kev sib cuag ncaj qha nrog lub wafer.

Yog epitaxy

Lub tais, uas tuav lub Si substrate rau loj hlob Si epitaxial daim, muab tso rau hauv cov tshuaj tiv thaiv chamber thiab ncaj qha hu rau lub wafer.

Lub nplhaib preheating yog nyob rau ntawm lub nplhaib sab nraud ntawm Si epitaxial substrate tais thiab yog siv rau calibration thiab cua sov. Nws yog muab tso rau hauv cov tshuaj tiv thaiv chamber thiab tsis ncaj qha mus cuag lub wafer.

Ib qho epitaxial susceptor, uas tuav Si substrate rau loj hlob Si epitaxial hlais, muab tso rau hauv cov tshuaj tiv thaiv chamber thiab ncaj qha hu rau wafer.

Epitaxial chim yog cov khoom tseem ceeb siv nyob rau hauv ntau yam semiconductor manufacturing txheej txheem, feem ntau yog siv nyob rau hauv MOCVD cov cuab yeej, nrog zoo heev thermal stability, tshuaj tiv thaiv thiab hnav tsis kam, heev haum rau siv nyob rau hauv high kub txheej txheem. Nws tiv tauj cov wafers.

| Lub cev muaj zog ntawm Recrystalized Silicon Carbide | |

| Khoom | Tus nqi |

| Ua haujlwm kub (°C) | 1600 ° C (nrog oxygen), 1700 ° C (txo ib puag ncig) |

| SiC cov ntsiab lus | > 99.96% |

| Dawb Si cov ntsiab lus | <0.1% |

| Qhov ntom ntom | 2.60-2.70 g / cm33 |

| Pom tseeb porosity | <16% |

| Compression zog | > 600 MPa |

| Txias dabtsi yog khoov zog | 80-90 MPa (20 ° C) |

| Kub dabtsi yog khoov zog | 90-100 MPa (1400 ° C) |

| Thermal expansion @ 1500 ° C | 4.70 10-6/°C |

| Thermal conductivity @ 1200 ° C | 23 W/m•K |

| Elastic modulus | 240 GPa |

| Thermal shock resistance | Zoo heev |

| Lub cev muaj zog ntawm Sintered Silicon Carbide | |

| Khoom | Tus nqi |

| Tshuaj muaj pes tsawg leeg | SiC> 95%, Si <5% |

| Kev ceev ceev | > 3.07 g/cm³ |

| Pom tseeb porosity | <0.1% |

| Modulus ntawm rupture ntawm 20 ℃ | 270 MPa rau |

| Modulus ntawm rupture ntawm 1200 ℃ | 290 MPa rau |

| Hardness ntawm 20 ℃ | 2400 Kg / hli |

| Fracture toughness ntawm 20% | 3.3 MPa · m1/2 |

| Thermal conductivity ntawm 1200 ℃ | 45 w/m |

| Thermal expansion ntawm 20-1200 ℃ | 4.5 1 × 10 -6/ ℃ |

| Max.ua haujlwm kub | 1400 ℃ |

| Thermal shock tsis kam ntawm 1200 ℃ | Zoo |

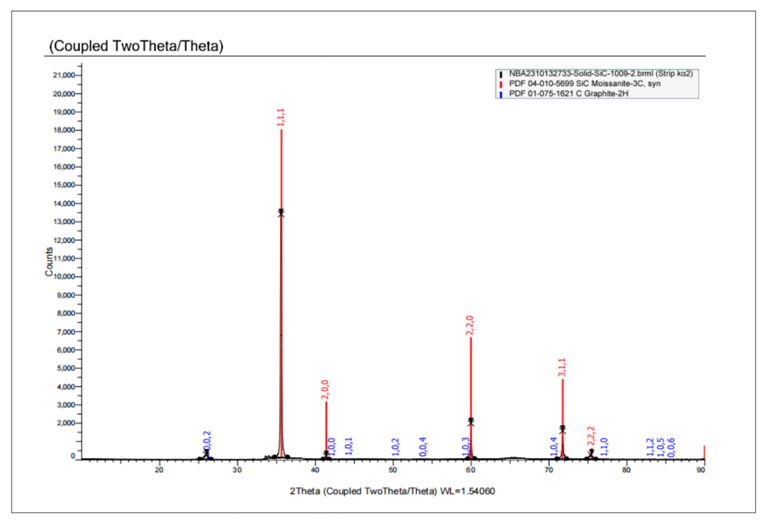

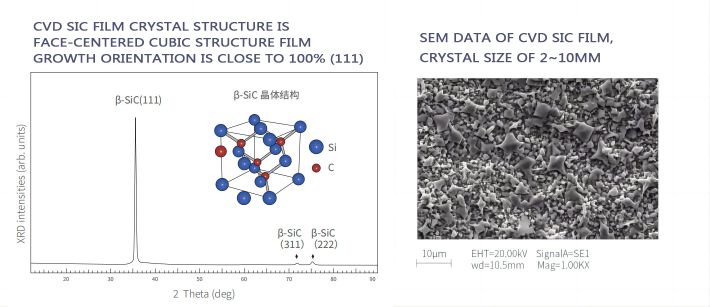

| Cov yam ntxwv ntawm lub cev ntawm CVD SiC films | |

| Khoom | Tus nqi |

| Crystal Structure | FCC β theem polycrystalline, feem ntau (111) taw qhia |

| Qhov ntom | 3.21 g / cm³ |

| Hardness 2500 | (500g load) |

| Loj Loj | 2 ~ 10 hli |

| Tshuaj Purity | 99.99995% |

| Thaum tshav kub kub muaj peev xwm | 6 40j kg-1· K-1 |

| Sublimation kub | 2700 ℃ |

| Flexural zog | 415 MPa RT 4-point |

| Young's Modulus | 430 Gpa 4pt khoov, 1300 ℃ |

| Thermal conductivity | 300 Wm-1· K-1 |

| Thermal Expansion (CTE) | 4.5 × 10-6 K -1 |

Cov yam ntxwv tseem ceeb

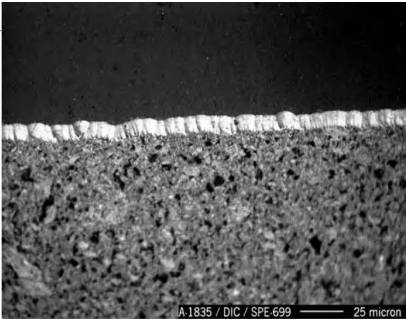

Qhov saum npoo yog ntom thiab tsis muaj pores.

High purity, tag nrho impurity cov ntsiab lus <20ppm, zoo airtightness.

Kev kub siab ua haujlwm, lub zog nce nrog nce kev siv kub, ncav cuag tus nqi siab tshaj ntawm 2750 ℃, sublimation ntawm 3600 ℃.

Tsawg elastic modulus, siab thermal conductivity, tsis tshua muaj thermal expansion coefficient, thiab zoo heev thermal shock kuj.

Kev ruaj ntseg tshuaj zoo, tiv taus cov kua qaub, alkali, ntsev, thiab cov organic reagents, thiab tsis cuam tshuam rau cov hlau molten, slag, thiab lwm yam corrosive media. Nws tsis oxidize ntau hauv cov huab cua hauv qab 400 C, thiab oxidation tus nqi nce ntawm 800 ℃.

Yog tias tsis tso cov pa tawm ntawm qhov kub thiab txias, nws tuaj yeem tswj tau lub tshuab nqus tsev ntawm 10-7mmHg ntawm thaj tsam 1800 ° C.

Daim ntawv thov khoom

Melting crucible rau evaporation hauv kev lag luam semiconductor.

Lub zog hluav taws xob hluav taws xob tube rooj vag.

Txhuam uas hu rau lub voltage regulator.

Graphite monochromator rau X-ray thiab neutron.

Ntau cov duab ntawm graphite substrates thiab atomic absorption raj txheej.

Pyrolytic carbon txheej nyhuv nyob rau hauv ib tug 500X microscope, nrog zoo thiab kaw ntom nti.

TaC txheej yog lub cim tshiab ntawm cov khoom siv kub kub, nrog kev ruaj ntseg zoo dua li SiC. Raws li cov txheej txheem corrosion-resistant, anti-oxidation txheej thiab hnav-resistant txheej, yuav siv tau nyob rau hauv ib puag ncig saum toj 2000C, dav siv nyob rau hauv aerospace ultra-siab kub kub kawg qhov chaw, lub thib peb tiam semiconductor ib qho kev loj hlob siv lead ua teb.

| Lub cev muaj zog ntawm TaC txheej | |

| Qhov ntom | 14.3 (g / cm3) |

| Tshwj xeeb emissivity | 0.3 |

| Thermal expansion coefficient | 6.3 10 / K |

| Hardness (HK) | 2000 HK |

| Kev tiv thaiv | 1 x 10-5 Ohm * cm |

| Thermal stability | <2500 ℃ |

| Graphite loj hloov | -10 ~ 20 hli |

| Txheej thickness | ≥220um tus nqi raug (35um ± 10um) |

Khoom CVD SILICON CARBIDE qhov chaw raug lees paub tias yog qhov kev xaiv tseem ceeb rau RTP / EPI rings thiab hauv paus thiab plasma etch kab noj hniav qhov chaw uas ua haujlwm ntawm qhov system siab yuav tsum tau ua haujlwm kub (> 1500 ° C), qhov yuav tsum tau ua rau purity yog qhov tshwj xeeb siab (> 99.9995%) thiab kev ua tau zoo tshwj xeeb tshaj yog thaum cov tshuaj tiv thaiv kab mob siab tshwj xeeb. Cov ntaub ntawv no tsis muaj cov theem nrab ntawm cov ntug ntawm cov nplej, yog li cov khoom siv tsim cov khoom tsawg dua li lwm cov ntaub ntawv. Tsis tas li ntawd, cov khoom no tuaj yeem ntxuav tau siv kub HF / HCI nrog me ntsis degradation, ua rau cov khoom tsawg dua thiab ua haujlwm ntev dua.