Hauv kev tsim khoom semiconductor, muaj cov txheej txheem hu ua "etching" thaum lub sij hawm ua cov substrate los yog nyias zaj duab xis tsim ntawm lub substrate. Kev txhim kho ntawm etching thev naus laus zis tau ua lub luag haujlwm hauv kev paub txog qhov kev twv ua los ntawm Intel tus tsim Gordon Moore hauv xyoo 1965 tias "kev sib koom ua ke ntawm cov transistors yuav ob npaug hauv 1.5 mus rau 2 xyoos" (feem ntau hu ua "Moore's Law").

Etching tsis yog ib qho "ntxiv" txheej txheem xws li deposition los yog bonding, tab sis ib tug txheej txheem "subtractive". Tsis tas li ntawd, raws li cov txheej txheem sib txawv, nws tau muab faib ua ob pawg, uas yog "ntub etching" thiab "dry etching". Txhawm rau muab nws yooj yim, lub qub yog ib txoj kev melting thiab tom kawg yog txoj kev khawb.

Hauv tsab xov xwm no, peb yuav piav qhia luv luv txog cov yam ntxwv thiab qhov sib txawv ntawm txhua qhov kev siv tshuab etching, ntub etching thiab qhuav etching, nrog rau cov ntawv thov rau txhua qhov tsim nyog.

Txheej txheem cej luam ntawm etching txheej txheem

Etching thev naus laus zis tau hais tias muaj keeb kwm hauv Tebchaws Europe hauv nruab nrab-15th caug xyoo. Thaum lub sij hawm ntawd, cov kua qaub tau nchuav rau hauv lub phaj tooj liab kom corrode tooj liab liab, ua ib qho intaglio. Cov txheej txheem kho deg uas siv los ntawm corrosion yog dav hu ua "etching."

Lub hom phiaj ntawm cov txheej txheem etching nyob rau hauv semiconductor manufacturing yog txiav lub substrate los yog zaj duab xis ntawm lub substrate raws li daim duab. Los ntawm kev rov ua cov kauj ruam npaj ntawm kev tsim cov yeeb yaj kiab, photolithography, thiab etching, cov qauv txheej txheem tau ua tiav rau hauv cov qauv peb sab.

Qhov sib txawv ntawm ntub etching thiab qhuav etching

Tom qab cov txheej txheem photolithography, cov txheej txheem nthuav tawm yog ntub lossis qhuav etched hauv txheej txheem etching.

Kev ntub dej etching siv cov tshuaj rau etch thiab khawb tawm ntawm qhov chaw. Txawm hais tias txoj kev no tuaj yeem ua tiav sai thiab pheej yig, nws qhov tsis zoo yog qhov kev ua haujlwm raug qis dua me ntsis. Yog li ntawd, qhuav etching tau yug los nyob ib ncig ntawm 1970. Qhuav etching tsis siv ib tug tov, tab sis siv roj los ntaus lub substrate nto mus khawb nws, uas yog yus muaj los ntawm high precision processing.

"Isotropy" thiab "Anisotropy"

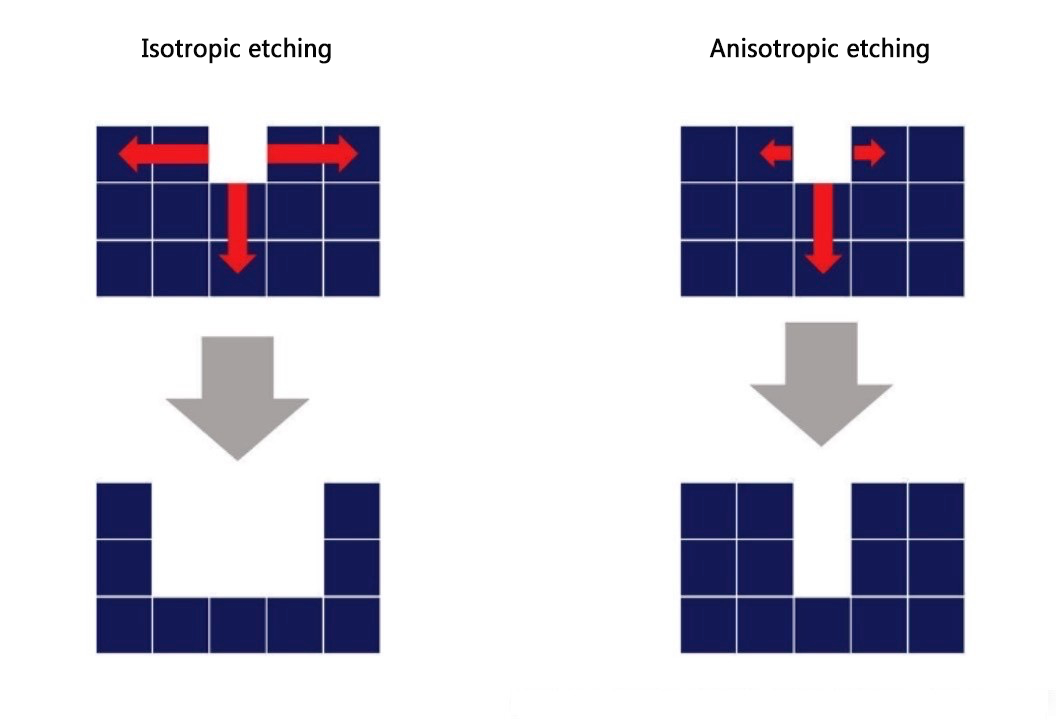

Thaum qhia txog qhov sib txawv ntawm ntub etching thiab qhuav etching, cov lus tseem ceeb yog "isotropic" thiab "anisotropic". Isotropy txhais tau hais tias lub cev lub cev ntawm cov teeb meem thiab qhov chaw tsis hloov nrog kev taw qhia, thiab anisotropy txhais tau hais tias lub cev lub cev ntawm cov teeb meem thiab qhov chaw sib txawv nrog cov kev taw qhia.

Isotropic etching txhais tau hais tias etching pib los ntawm tib tus nqi nyob ib ncig ntawm ib qho chaw, thiab anisotropic etching txhais tau hais tias etching pib nyob rau hauv ntau cov lus qhia nyob ib ncig ntawm ib tug tej yam taw tes. Piv txwv li, nyob rau hauv etching thaum lub sij hawm semiconductor manufacturing, anisotropic etching feem ntau yog xaiv kom tsuas yog lub hom phiaj kev taw qhia yog scraped, tawm hauv lwm cov lus qhia zoo.

Cov duab ntawm "Isotropic Et" thiab "Anisotropic Etch"

Cov duab ntawm "Isotropic Et" thiab "Anisotropic Etch"

Kev ntub dej etching siv cov tshuaj.

Kev ntub dej ntub dej siv cov tshuaj tiv thaiv ntawm cov tshuaj lom neeg thiab cov substrate. Nrog rau txoj kev no, anisotropic etching tsis yooj yim sua, tab sis nws yog qhov nyuaj dua li isotropic etching. Muaj ntau qhov kev txwv ntawm kev sib xyaw ua ke ntawm cov kev daws teeb meem thiab cov khoom siv, thiab cov xwm txheej xws li kub substrate, kev daws teeb meem, thiab cov nyiaj ntxiv yuav tsum tau tswj nruj me ntsis.

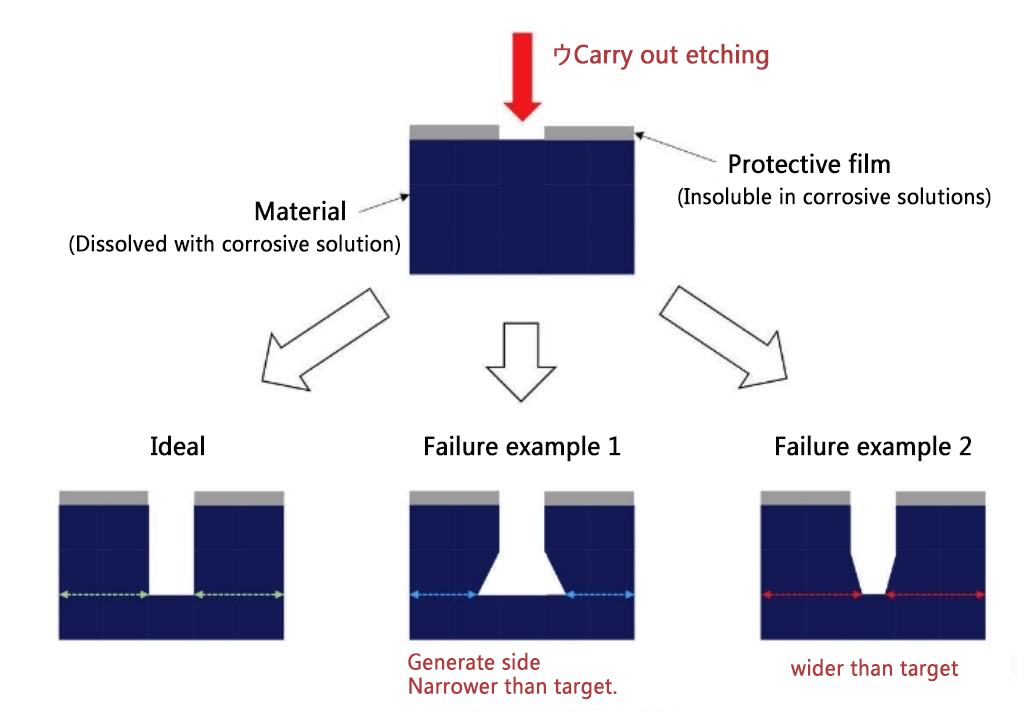

Tsis muaj teeb meem zoo li cas cov kev mob raug kho, ntub etching yog ib qho nyuaj rau kev ua tiav zoo hauv qab 1 μm. Ib qho laj thawj rau qhov no yog qhov yuav tsum tau tswj xyuas sab etching.

Undercutting yog ib qho tshwm sim tseem hu ua undercutting. Txawm hais tias nws cia siab tias cov khoom yuav raug yaj tsuas yog nyob rau hauv txoj kab ntsug (qhov tob qhov taw qhia) los ntawm kev ntub dej ntub dej, nws tsis tuaj yeem tiv thaiv kev daws teeb meem los ntawm kev sib tsoo, yog li qhov kev sib cais ntawm cov khoom nyob rau hauv qhov sib npaug yuav inevitably txuas ntxiv mus. . Vim qhov tshwm sim no, ntub etching randomly tsim cov ntu uas nqaim dua li lub hom phiaj dav. Nyob rau hauv txoj kev no, thaum ua cov khoom lag luam uas yuav tsum tau muaj kev tswj xyuas tam sim no, qhov kev tsim tawm yog tsawg thiab qhov tseeb yog qhov tsis ntseeg.

Piv txwv ntawm Kev Ua Tsis Zoo hauv Kev ntub dej ntub dej

Piv txwv ntawm Kev Ua Tsis Zoo hauv Kev ntub dej ntub dej

Yog vim li cas qhuav etching yog haum rau micromachining

Cov lus piav qhia ntawm Cov Khoom Uas Qhuav etching haum rau anisotropic etching yog siv nyob rau hauv semiconductor manufacturing txheej txheem uas yuav tsum tau high-precision ua. Qhuav etching feem ntau hu ua reactive ion etching (RIE), uas tej zaum kuj muaj xws li plasma etching thiab sputter etching nyob rau hauv ib tug dav dav, tab sis tsab xov xwm no yuav tsom rau RIE.

Txhawm rau piav qhia vim li cas anisotropic etching yog yooj yim dua nrog qhuav etching, cia peb saib zoo dua ntawm cov txheej txheem RIE. Nws yog ib qho yooj yim to taub los ntawm kev faib cov txheej txheem ntawm qhuav etching thiab scraping tawm lub substrate rau ob hom: "tshuaj etching" thiab "lub cev etching".

Tshuaj etching tshwm sim nyob rau hauv peb kauj ruam. Ua ntej, cov roj reactive yog adsorbed rau ntawm qhov chaw. Cov khoom siv tshuaj tiv thaiv yog tsim los ntawm cov tshuaj tiv thaiv roj thiab cov khoom siv substrate, thiab thaum kawg cov khoom siv tshuaj tiv thaiv yog desorbed. Nyob rau hauv lub cev tom qab etching, lub substrate yog etched vertically downward los ntawm kev siv argon gas vertically rau lub substrate.

Tshuaj etching tshwm sim isotropically, thaum lub cev etching tuaj yeem tshwm sim anisotropically los ntawm kev tswj cov kev taw qhia ntawm daim ntawv thov roj. Vim yog lub cev etching no, qhuav etching tso cai rau ntau yam kev tswj ntawm etching kev taw qhia tshaj ntub etching.

Qhuav thiab ntub etching kuj yuav tsum tau tib yam nruj raws li ntub etching, tab sis nws muaj ntau dua reproducibility dua ntub etching thiab muaj ntau yam yooj yim-rau-tswj khoom. Yog li ntawd, tsis muaj qhov tsis ntseeg tias qhuav etching yog qhov tsim nyog rau kev tsim khoom lag luam.

Vim li cas ntub Etching tseem xav tau

Thaum koj nkag siab qhov seemingly omnipotent qhuav etching, koj yuav xav tias yog vim li cas ntub etching tseem muaj. Txawm li cas los xij, yog vim li cas yooj yim: ntub etching ua rau cov khoom pheej yig dua.

Lub ntsiab sib txawv ntawm qhuav etching thiab ntub etching yog nqi. Cov tshuaj siv rau hauv ntub etching tsis yog kim, thiab tus nqi ntawm cov khoom nws tus kheej yog hais txog 1/10 ntawm cov khoom siv qhuav etching. Tsis tas li ntawd, lub sijhawm ua haujlwm luv luv thiab ntau lub substrates tuaj yeem ua tiav tib lub sijhawm, txo cov nqi tsim khoom. Yog li ntawd, peb tuaj yeem khaws cov khoom lag luam qis, ua rau peb muaj txiaj ntsig zoo dua peb cov neeg sib tw. Yog tias qhov yuav tsum tau ua kom raug tsis yog siab, ntau lub tuam txhab yuav xaiv cov etching ntub dej rau cov khoom loj.

Cov txheej txheem etching tau qhia raws li cov txheej txheem uas ua lub luag haujlwm hauv microfabrication technology. Cov txheej txheem etching yog roughly muab faib ua ntub etching thiab qhuav etching. Yog tias tus nqi tseem ceeb, qhov qub yog qhov zoo dua, thiab yog tias microprocessing qis dua 1 μm yuav tsum tau, qhov tom kawg yog qhov zoo dua. Qhov zoo tshaj plaws, cov txheej txheem tuaj yeem xaiv raws li cov khoom tsim thiab tus nqi, tsis yog qhov twg zoo dua.

Post lub sij hawm: Apr-16-2024