Cov txheej txheem qhuav etching feem ntau muaj plaub lub xeev: ua ntej etching, ib nrab etching, tsuas yog etching, thiab tshaj etching. Cov yam ntxwv tseem ceeb yog etching tus nqi, xaiv qhov tseem ceeb, qhov loj me, qhov sib xws, thiab qhov kawg nrhiav kom pom.

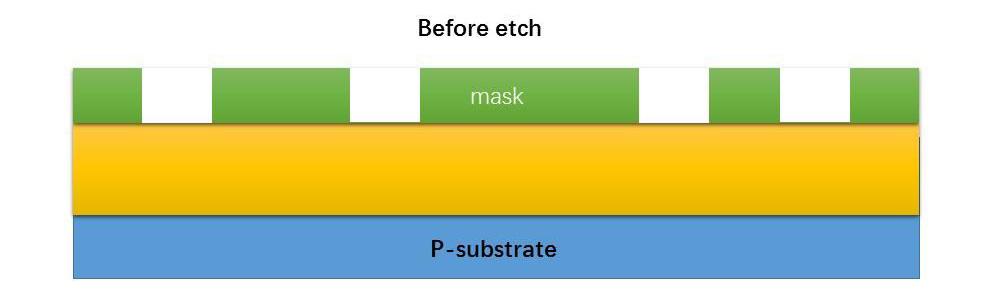

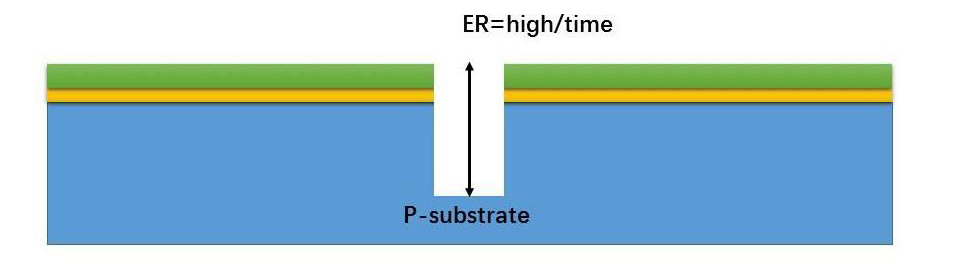

Daim duab 1 Ua ntej etching

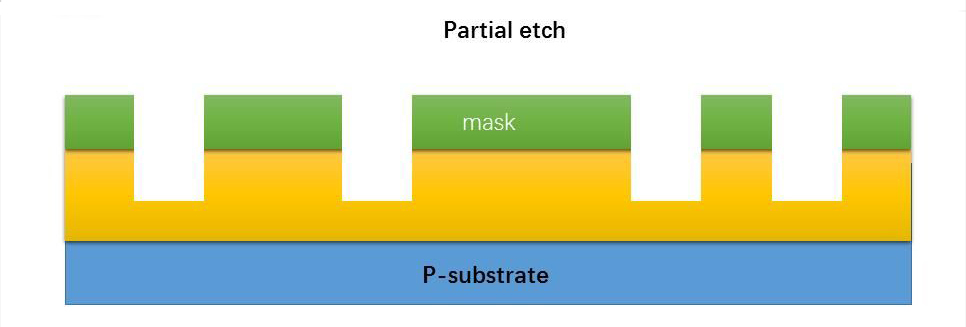

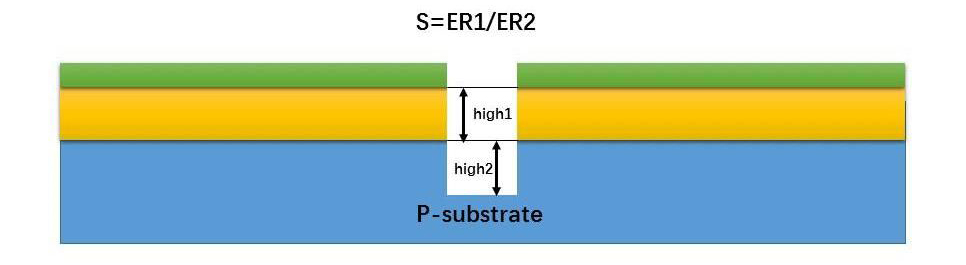

Daim duab 2 Ib nrab etching

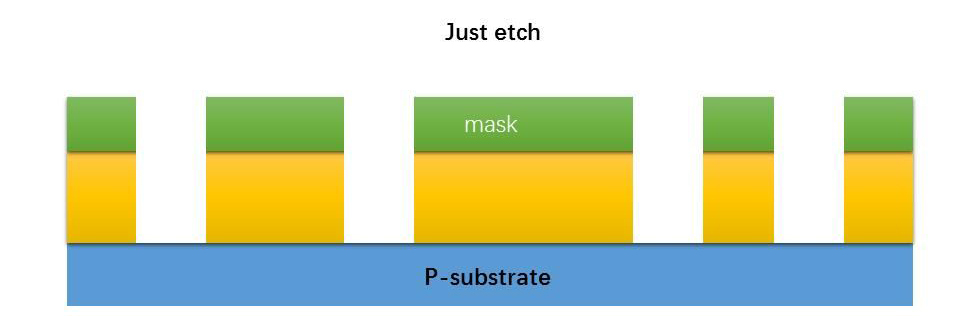

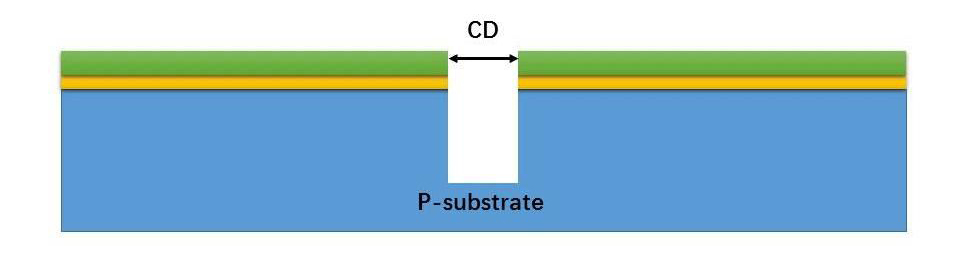

Daim duab 3 Tsuas yog etching

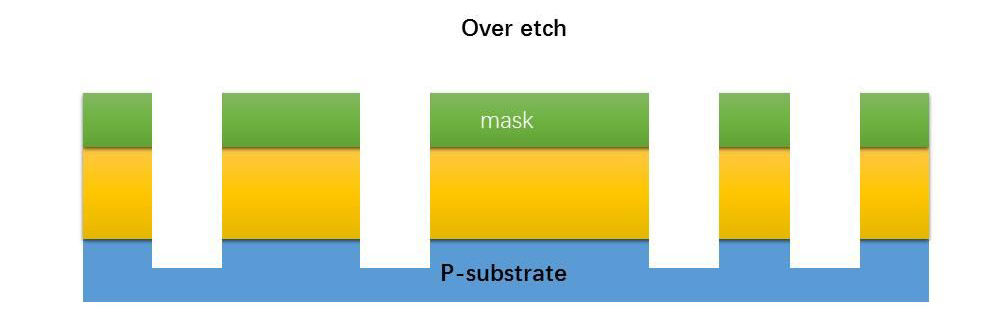

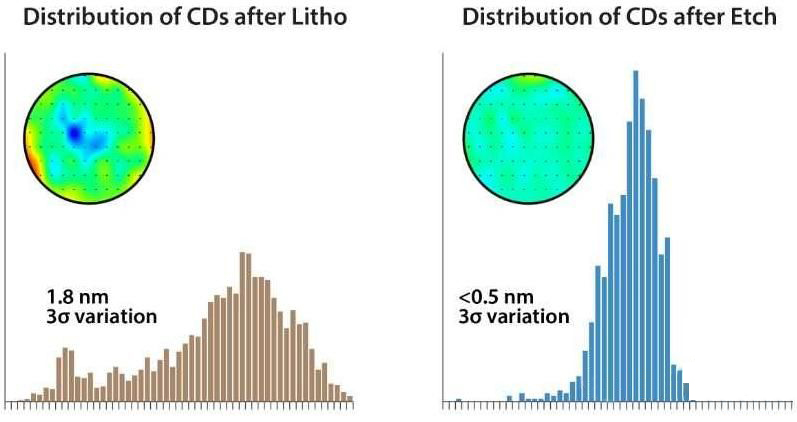

Daim duab 4 Over etching

(1) Etching tus nqi: qhov tob lossis tuab ntawm cov khoom etched tshem tawm ib lub sijhawm.

Daim duab 5 Etching rate diagram

(2) Selectivity: qhov piv ntawm etching tus nqi sib txawv etching cov ntaub ntawv.

Daim duab 6 Selectivity diagram

(3) Qhov tseem ceeb: qhov loj ntawm cov qauv hauv ib cheeb tsam tshwj xeeb tom qab etching tiav.

Daim duab 7 Critical dimension diagram

(4) Uniformity: ntsuas qhov sib xws ntawm qhov tseem ceeb etching dimension (CD), feem ntau yog cim los ntawm daim ntawv qhia tag nrho ntawm CD, tus qauv yog: U = (Max-Min) / 2 * AVG.

Daim duab 8 Uniformity Schematic Diagram

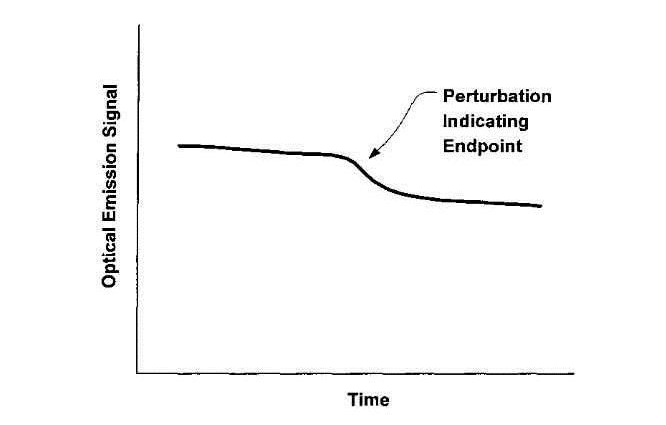

(5) Qhov kawg point nrhiav kom tau: Thaum lub sij hawm etching txheej txheem, qhov kev hloov ntawm lub teeb siv yog tas li pom. Thaum ib qho kev siv lub teeb nce los yog ntog heev, lub etching raug txiav los ua kom tiav ntawm ib txheej ntawm zaj duab xis etching.

Daim duab 9 End point schematic daim duab

Nyob rau hauv qhuav etching, cov roj tau zoo siab los ntawm cov zaus siab (tsuas yog 13.56 MHz lossis 2.45 GHz). Ntawm qhov siab ntawm 1 txog 100 Pa, nws txhais tau tias txoj kev dawb yog ob peb millimeters mus rau ob peb centimeters. Muaj peb yam tseem ceeb ntawm qhuav etching:

•Lub cev qhuav etching: accelerated hais lub cev hnav lub wafer nto

•Tshuaj qhuav etching: gas reacts chemically nrog wafer nto

•Tshuaj lub cev qhuav etching: lub cev etching txheej txheem nrog cov yam ntxwv tshuaj

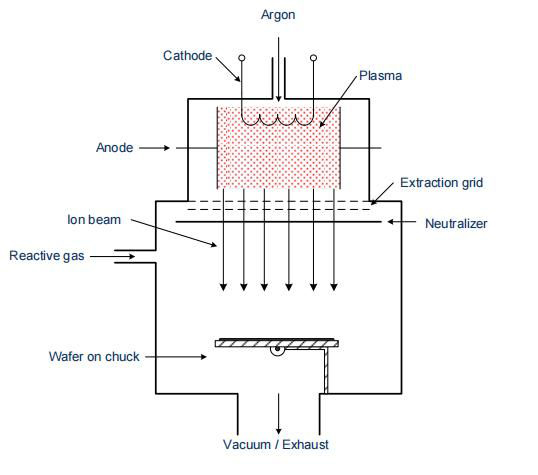

1. Ion beam etching

Ion beam etching (Ion Beam Etching) yog lub cev qhuav txheej txheem uas siv lub zog loj argon ion beam nrog lub zog ntawm li 1 txog 3 keV los irradiate cov khoom nto. Lub zog ntawm ion beam ua rau nws cuam tshuam thiab tshem tawm cov khoom nto. Cov txheej txheem etching yog anisotropic nyob rau hauv rooj plaub ntawm ntsug lossis oblique xwm txheej ion kab teeb. Txawm li cas los xij, vim nws tsis muaj kev xaiv, tsis muaj qhov sib txawv ntawm cov khoom sib txawv. Cov gases generated thiab cov ntaub ntawv etched yog tas los ntawm lub tshuab nqus tsev twj tso kua mis, tab sis txij li thaum cov tshuaj tiv thaiv cov khoom tsis yog gases, hais tias yog tso rau ntawm lub wafer los yog chamber phab ntsa.

Txhawm rau tiv thaiv kev tsim cov khoom, cov roj thib ob tuaj yeem nkag mus rau hauv lub chamber. Cov roj no yuav hnov mob nrog argon ions thiab ua rau lub cev thiab tshuaj etching txheej txheem. Ib feem ntawm cov roj yuav hnov mob nrog cov khoom siv saum npoo av, tab sis nws tseem yuav hnov mob nrog cov khoom polished los ua cov khoom siv roj. Yuav luag txhua yam khoom siv tuaj yeem etched los ntawm txoj kev no. Vim yog cov hluav taws xob ntsug, qhov hnav ntawm cov phab ntsa ntsug yog me me (siab anisotropy). Txawm li cas los xij, vim nws qhov kev xaiv qis thiab qeeb etching tus nqi, cov txheej txheem no tsis tshua muaj siv hauv kev tsim khoom semiconductor tam sim no.

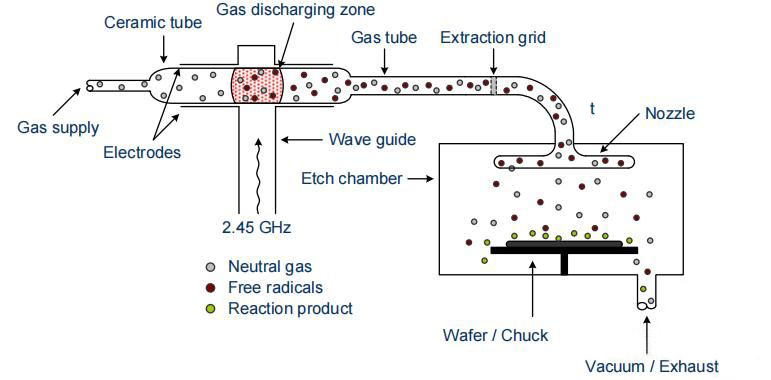

2. Plasma etching

Plasma etching yog cov txheej txheem tshuaj etching, tseem hu ua tshuaj qhuav etching. Nws qhov zoo dua yog tias nws tsis ua rau ion puas tsuaj rau lub wafer nto. Txij li cov hom nquag nyob rau hauv cov roj etching yog pub dawb rau kev txav mus los thiab cov txheej txheem etching yog isotropic, txoj kev no yog tsim rau tshem tawm tag nrho cov yeeb yaj kiab txheej (piv txwv li, ntxuav sab nraub qaum tom qab thermal oxidation).

Lub reactor downstream yog ib hom reactor feem ntau siv rau plasma etching. Nyob rau hauv lub reactor no, cov ntshav yog tsim los ntawm kev cuam tshuam ionization nyob rau hauv ib tug high-frequency hluav taws xob teb ntawm 2.45GHz thiab sib cais los ntawm lub wafer.

Hauv thaj chaw tso pa tawm, ntau yam khoom tsim tawm vim muaj kev cuam tshuam thiab kev zoo siab, suav nrog cov dawb radicals. Dawb radicals yog nruab nrab atoms los yog molecules nrog unsaturated electrons, yog li lawv yog heev reactive. Hauv cov txheej txheem plasma etching, qee cov roj nruab nrab, xws li tetrafluoromethane (CF4), feem ntau yog siv, uas tau nkag mus rau hauv cov pa paug hauv cheeb tsam los tsim cov hom tsiaj los ntawm ionization lossis decomposition.

Piv txwv li, hauv CF4 roj, nws tau nkag mus rau hauv cov pa paug hauv cheeb tsam thiab decomposed rau hauv fluorine radicals (F) thiab carbon difluoride molecules (CF2). Ib yam li ntawd, fluorine (F) tuaj yeem decomposed los ntawm CF4 los ntawm kev ntxiv oxygen (O2).

2 CF4 + O2 —> 2 COF2 + 2 F2

Cov fluorine molecule tuaj yeem faib ua ob qho kev ywj pheej fluorine atoms nyob rau hauv lub zog ntawm cov pa tawm hauv cheeb tsam, txhua tus yog fluorine dawb radical. Txij li thaum txhua lub fluorine atom muaj xya valence electrons thiab nyhav kom ua tiav cov khoom siv hluav taws xob ntawm cov roj inert, lawv txhua tus muaj zog heev. Ntxiv nrog rau qhov nruab nrab fluorine dawb radicals, yuav muaj cov khoom siv xws li CF + 4, CF + 3, CF + 2, thiab lwm yam hauv cheeb tsam tso pa tawm. Tom qab ntawd, tag nrho cov khoom no thiab cov dawb radicals tau nkag mus rau hauv lub etching chamber los ntawm cov raj ceramic.

Cov khoom raug them tuaj yeem raug thaiv los ntawm kev rho tawm gratings lossis rov ua dua nyob rau hauv cov txheej txheem ntawm kev tsim cov khoom nruab nrab los tswj lawv tus cwj pwm hauv lub etching chamber. Cov fluorine dawb radicals kuj tseem yuav tau txais ib nrab recombination, tab sis tseem muaj zog txaus nkag mus rau hauv lub etching chamber, reacts chemically ntawm lub wafer nto thiab ua rau cov khoom stripping. Lwm cov khoom nruab nrab tsis koom nrog cov txheej txheem etching thiab tau noj nrog rau cov khoom siv tshuaj tiv thaiv.

Piv txwv ntawm nyias zaj duab xis uas tuaj yeem etched hauv plasma etching:

• Silicon: Si + 4F —> SiF4

• Silicon dioxide: SiO2 + 4F —> SiF4 + O2

• Silicon nitride: Si3N4 + 12F—> 3SiF4 + 2N2

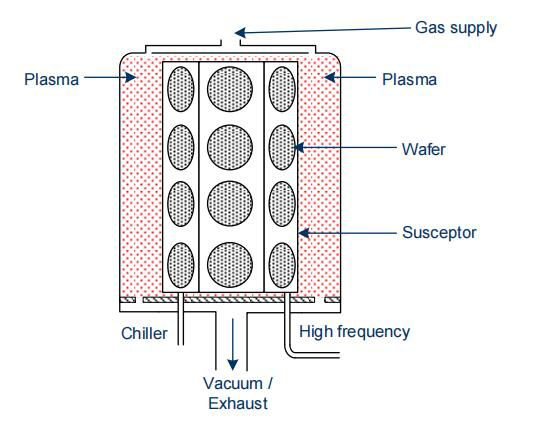

3.Reactive ion etching (RIE)

Reactive ion etching yog cov txheej txheem tshuaj-lub cev etching uas tuaj yeem tswj tau qhov kev xaiv zoo, etching profile, etching tus nqi, uniformity thiab repeatability. Nws tuaj yeem ua tiav isotropic thiab anisotropic etching profiles thiab yog li ntawd yog ib qho ntawm cov txheej txheem tseem ceeb tshaj plaws rau kev tsim ntau cov yeeb yaj kiab nyias hauv kev tsim khoom semiconductor.

Thaum lub sij hawm RIE, lub wafer muab tso rau ntawm ib tug high-frequency electrode (HF electrode). Los ntawm kev cuam tshuam ionization, lub plasma yog tsim nyob rau hauv uas cov electrons dawb thiab zoo ions muaj nyob. Yog tias qhov hluav taws xob zoo tau siv rau HF electrode, cov hluav taws xob dawb sib sau ua ke ntawm electrode nto thiab tsis tuaj yeem tawm ntawm electrode dua vim lawv cov electron affinity. Yog li ntawd, cov electrodes raug them mus rau -1000V (kev tsis ncaj ncees voltage) kom cov ions qeeb tsis tuaj yeem ua raws li cov hluav taws xob hloov pauv mus rau qhov tsis zoo electrode.

Thaum lub sij hawm ion etching (RIE), yog tias txoj kev tsis pub dawb ntawm cov ions siab, lawv tsoo lub wafer nto nyob rau hauv ib qho kev taw qhia yuav luag. Ua li no, cov ions nrawm nrawm tawm ntawm cov khoom siv thiab tsim cov tshuaj tiv thaiv los ntawm lub cev etching. Txij li thaum lub lateral sidewalls tsis cuam tshuam, etch profile tseem anisotropic thiab qhov hnav yog me me. Txawm li cas los xij, qhov kev xaiv tsis yog siab heev vim tias lub cev etching txheej txheem kuj tshwm sim. Tsis tas li ntawd, qhov nrawm ntawm cov ions ua rau muaj kev puas tsuaj rau wafer nto, uas yuav tsum tau thermal annealing los kho.

Cov tshuaj lom neeg ntawm cov txheej txheem etching yog ua tiav los ntawm cov dawb radicals reacting nrog rau saum npoo thiab cov ions lub cev ntaus cov khoom kom nws tsis rov qab los ntawm cov wafer los yog cov phab ntsa chamber, zam qhov redeposition phenomenon xws li ion beam etching. Thaum nce cov roj siab nyob rau hauv lub etching chamber, qhov txhais tau tias dawb txoj kev ntawm cov ions yog txo, uas ua rau kom tus naj npawb ntawm kev sib tsoo ntawm cov ions thiab cov roj molecules, thiab cov ions tau tawg mus rau ntau qhov sib txawv. Qhov no ua rau tsis tshua muaj kev taw qhia etching, ua rau cov txheej txheem etching ntau tshuaj.

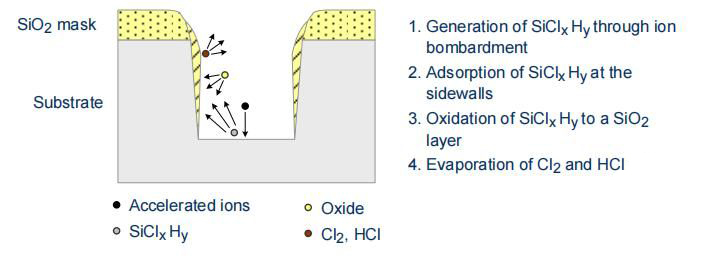

Anisotropic etch profiles yog tiav los ntawm passivating lub sidewalls thaum silicon etching. Oxygen yog nkag mus rau hauv lub etching chamber, qhov twg nws reacts nrog lub etched silicon los ua silicon dioxide, uas yog tso rau ntawm ntsug sidewalls. Vim yog ion bombardment, oxide txheej ntawm cov kab rov tav raug tshem tawm, tso cai rau cov txheej txheem etching txuas ntxiv mus. Txoj kev no tuaj yeem tswj cov duab ntawm qhov etch profile thiab qhov steepness ntawm sidewalls.

Tus nqi etch yog cuam tshuam los ntawm cov yam ntxwv xws li siab, HF lub tshuab hluav taws xob fais fab, cov txheej txheem roj, qhov tseeb ntawm cov roj ntws thiab qhov kub thiab txias, thiab nws qhov kev hloov pauv tau khaws cia qis dua 15%. Anisotropy nce nrog nce HF lub zog, txo qhov siab thiab txo qhov kub. Lub uniformity ntawm cov txheej txheem etching yog txiav txim los ntawm cov pa roj, electrode spacing thiab electrode khoom. Yog hais tias lub electrode nrug me me dhau lawm, lub plasma tsis tuaj yeem sib npaug sib npaug, ua rau tsis sib xws. Ua kom cov electrode nyob deb yuav txo tau tus nqi etching vim hais tias cov plasma faib nyob rau hauv ib tug loj ntim. Cov pa roj carbon monoxide yog cov khoom siv hluav taws xob nyiam vim tias nws tsim cov plasma tsis sib xws kom cov ntug ntawm lub wafer cuam tshuam zoo ib yam li qhov nruab nrab ntawm lub wafer.

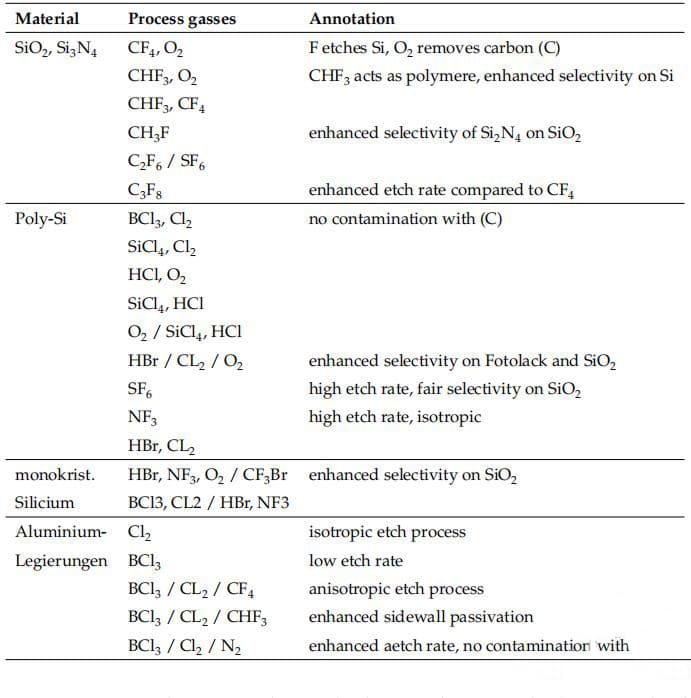

Cov txheej txheem roj ua lub luag haujlwm tseem ceeb hauv kev xaiv thiab etching tus nqi. Rau silicon thiab silicon tebchaw, fluorine thiab chlorine yog siv los ua kom tiav etching. Xaiv cov roj uas tsim nyog, kho cov roj ntws thiab siab, thiab tswj hwm lwm yam xws li kub thiab lub zog hauv cov txheej txheem tuaj yeem ua tiav qhov xav tau etch tus nqi, xaiv, thiab sib xws. Kev ua kom zoo ntawm cov kev ntsuas no feem ntau yog kho rau cov ntawv thov sib txawv thiab cov khoom siv.

Cov txheej txheem etching tsis txwv rau ib qho roj, roj sib tov, lossis cov txheej txheem ruaj khov. Piv txwv li, ib txwm oxide ntawm polysilicon tuaj yeem raug tshem tawm ua ntej nrog tus nqi siab thiab kev xaiv qis, thaum lub polysilicon tuaj yeem raug etched tom qab nrog kev xaiv ntau dua piv rau cov txheej hauv qab.

———————————————————————————————————————————————————————— ————————————————

Semicera tuaj yeem muab taugraphite qhov chaw, soft/rigid xav, silicon carbide qhov chaw,CVD silicon carbide qhov chaw, thiabSiC/TaC coated qhov chaw nrog hauv 30 hnub.

Yog tias koj txaus siab rau cov khoom lag luam semiconductor saum toj no,thov tsis txhob yig tiv tauj peb thawj zaug.

Tel: +86-13373889683

WhatsApp: + 86-15957878134

Email: sales01@semi-cera.com

Post lub sij hawm: Sep-12-2024