Cov khoom siv hluav taws xob semiconductor tuav lub luag haujlwm tseem ceeb hauv cov tshuab hluav taws xob hluav taws xob, tshwj xeeb tshaj yog nyob rau hauv cov ntsiab lus ntawm kev txhim kho sai ntawm cov thev naus laus zis xws li kev txawj ntse, 5G kev sib txuas lus thiab lub zog tshiab, cov kev xav tau ntawm lawv tau raug txhim kho.

Silicon carbide(4H-SiC) tau dhau los ua cov khoom siv zoo tshaj plaws rau kev tsim cov khoom siv hluav taws xob semiconductor vim nws qhov zoo xws li qhov dav bandgap, siab thermal conductivity, siab tawg teb zog, siab saturation drift tus nqi, tshuaj stability thiab hluav taws xob tsis kam. Txawm li cas los xij, 4H-SiC muaj siab hardness, siab brittleness, muaj zog tshuaj inertness, thiab siab ua nyuaj. Qhov zoo ntawm nws cov substrate wafer yog qhov tseem ceeb rau kev siv cov khoom siv loj.

Yog li ntawd, kev txhim kho qhov zoo ntawm 4H-SiC substrate wafers, tshwj xeeb tshaj yog tshem tawm cov txheej puas ntawm cov txheej txheem wafer, yog tus yuam sij kom ua tiav kev ua tau zoo, qis-tsawg thiab zoo 4H-SiC substrate wafer ua.

Kev sim

Qhov kev sim siv 4-nti N-hom 4H-SiC ingot loj hlob los ntawm lub cev vapor thauj txoj kev, uas yog ua tiav los ntawm cov hlau txiav, sib tsoo, sib tsoo ntxhib, zoo sib tsoo thiab polishing, thiab sau cov thickness ntawm C nto thiab Si nto. thiab qhov kawg wafer thickness nyob rau hauv txhua txoj kev.

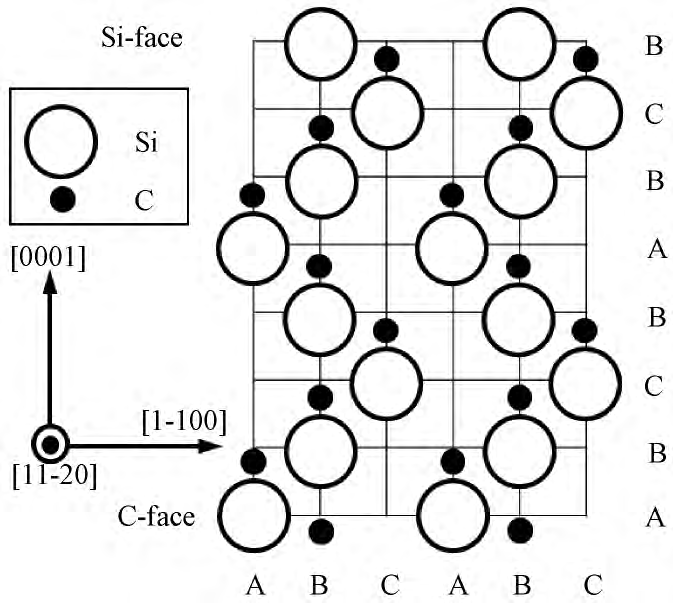

Daim duab 1 Schematic daim duab ntawm 4H-SiC siv lead ua qauv

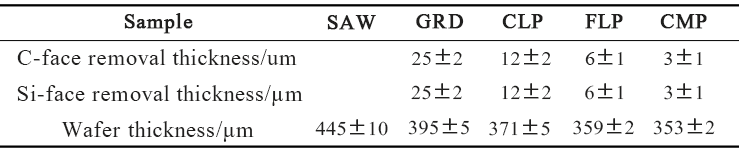

Daim duab 2 Thickness tshem tawm ntawm C-sab thiab Si-sab ntawm 4H-SiC wafertom qab sib txawv ua cov kauj ruam thiab thickness ntawm wafer tom qab ua

Lub thickness, deg morphology, roughness thiab mechanical zog ntawm lub wafer tau tag nrho cov yam ntxwv ntawm wafer geometry parameter tester, sib txawv cuam tshuam microscope, atomic force microscope, nto roughness ntsuas ntsuas thiab nanoindenter. Tsis tas li ntawd, high-resolution X-ray diffractometer tau siv los ntsuas cov siv lead ua zoo ntawm wafer.

Cov kauj ruam kev sim thiab cov kev sim no muab cov ncauj lus qhia ntxaws ntxaws rau kev kawm txog kev tshem tawm cov khoom siv thiab qhov zoo ntawm qhov chaw thaum ua tiav ntawm 4H-SiC wafers.

Los ntawm kev sim, cov kws tshawb fawb tau soj ntsuam cov kev hloov pauv ntawm cov khoom tshem tawm (MRR), qhov chaw morphology thiab roughness, nrog rau cov khoom siv kho tshuab thiab siv lead ua zoo ntawm 4H-SiC wafersnyob rau hauv kev sib txawv cov kauj ruam (hlau txiav, sib tsoo, ntxhib sib tsoo, nplua sib tsoo, polishing).

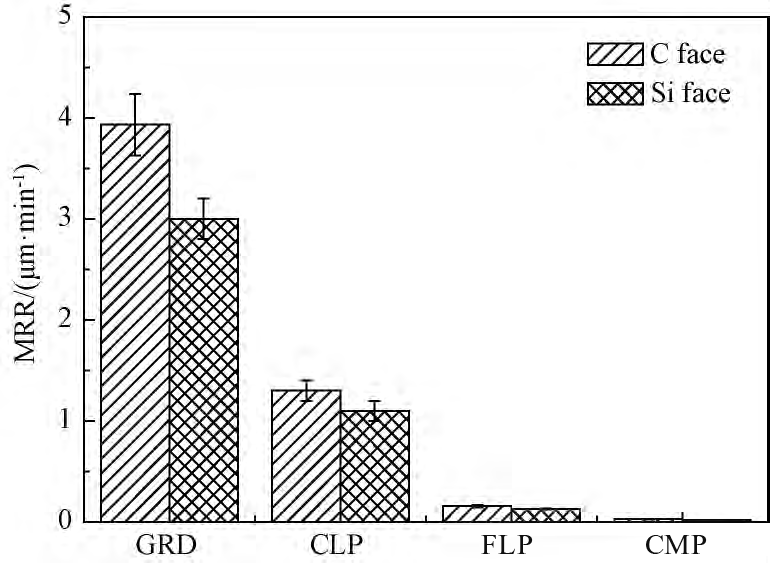

Daim duab 3 Cov khoom tshem tawm tus nqi ntawm C-ntsej muag thiab Si-face ntawm 4H-SiC wafernyob rau hauv cov txheej txheem sib txawv

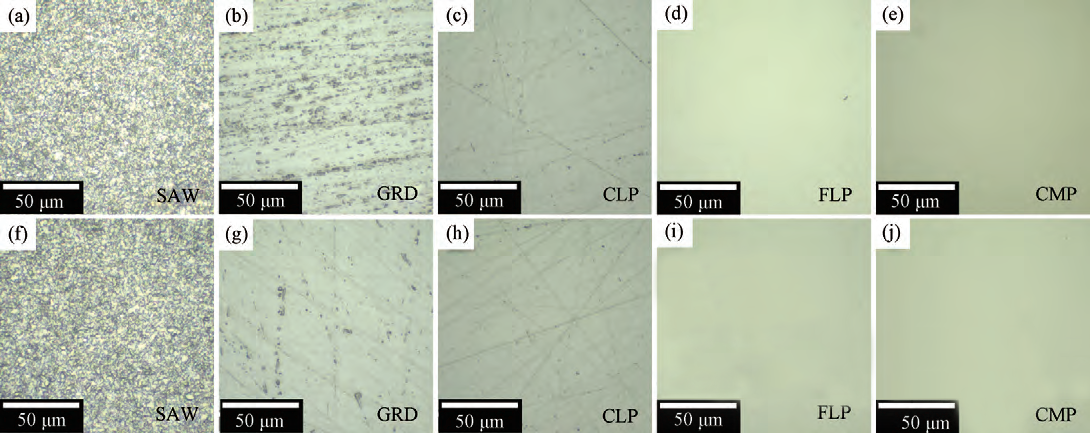

Txoj kev tshawb nrhiav pom tias vim yog anisotropy ntawm cov khoom siv ntawm cov khoom siv lead ua sib txawv ntawm 4H-SiC, muaj qhov sib txawv hauv MRR ntawm C-face thiab Si-face nyob rau hauv tib txoj kev, thiab MRR ntawm C-lub ntsej muag yog qhov siab dua. uas Si-face. Nrog rau kev nce qib ntawm kev ua cov kauj ruam, qhov saum npoo morphology thiab roughness ntawm 4H-SiC wafers maj mam optimized. Tom qab polishing, Ra ntawm C-ntsej muag yog 0.24nm, thiab Ra ntawm Si-face ncav cuag 0.14nm, uas tuaj yeem ua tau raws li qhov xav tau ntawm kev loj hlob epitaxial.

Daim duab 4 Optical microscope dluab ntawm C nto (a ~ e) thiab Si nto (f ~ j) ntawm 4H-SiC wafer tom qab sib txawv cov kauj ruam

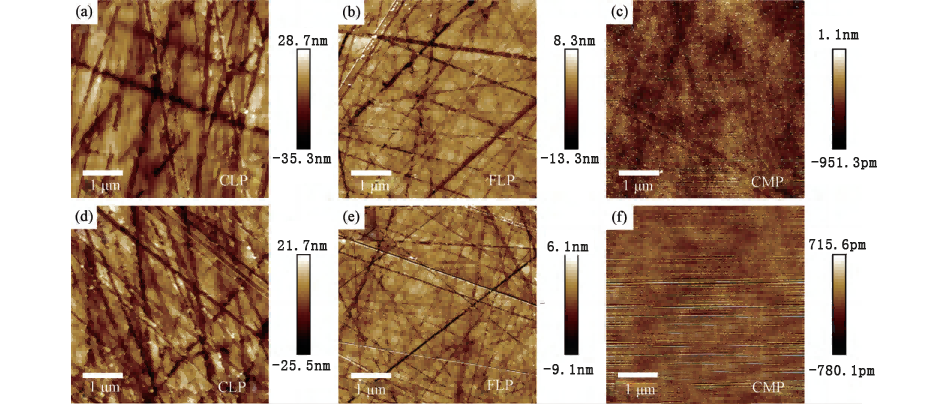

Daim duab 5 Atomic force microscope duab ntawm C nto (a ~ c) thiab Si nto (d ~ f) ntawm 4H-SiC wafer tom qab CLP, FLP thiab CMP ua cov kauj ruam

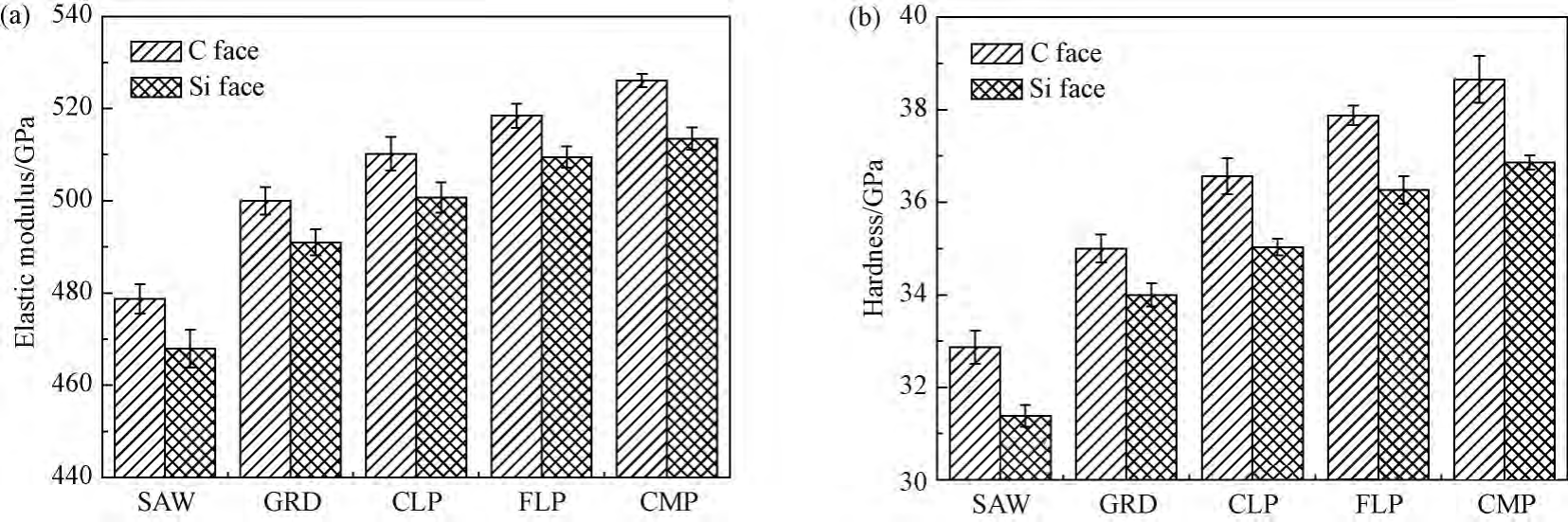

Daim duab 6 (a) elastic modulus thiab (b) hardness ntawm C nto thiab Si nto ntawm 4H-SiC wafer tom qab sib txawv cov kauj ruam

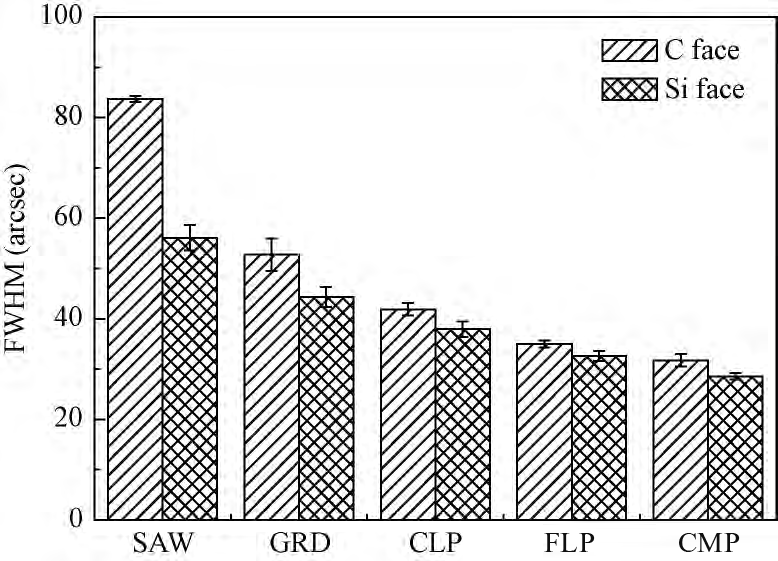

Kev ntsuas cov cuab yeej cuab yeej qhia tau hais tias C nto ntawm lub wafer muaj qhov tsis zoo dua li cov khoom siv Si saum npoo, ntau dua ntawm cov pob txha tawg thaum ua tiav, tshem tawm cov khoom sai dua, thiab qhov tsis zoo ntawm qhov morphology thiab roughness. Tshem tawm cov txheej puas ntawm cov txheej txheem ua tiav yog tus yuam sij rau kev txhim kho qhov zoo ntawm wafer. Qhov ib nrab-siab dav ntawm 4H-SiC (0004) rocking nkhaus yuav siv tau los intuitively thiab raug tus yam ntxwv thiab txheeb xyuas qhov kev puas tsuaj txheej txheej ntawm lub wafer.

Daim duab 7 (0004) rocking nkhaus ib nrab-dav ntawm C-ntsej muag thiab Si-face ntawm 4H-SiC wafer tom qab sib txawv cov kauj ruam

Cov txiaj ntsig kev tshawb fawb pom tau tias cov txheej txheem kev puas tsuaj ntawm lub wafer tuaj yeem maj mam tshem tawm tom qab 4H-SiC wafer ua, uas ua kom zoo dua qhov zoo ntawm lub wafer thiab muab cov ntaub ntawv siv rau kev ua haujlwm siab, qis-tsawg thiab ua haujlwm zoo. ntawm 4H-SiC substrate wafers.

Cov kws tshawb fawb tau ua tiav 4H-SiC wafers los ntawm cov txheej txheem sib txawv xws li kev txiav hlau, sib tsoo, sib tsoo ntxhib, sib tsoo zoo thiab polishing, thiab kawm txog cov teebmeem ntawm cov txheej txheem no ntawm qhov zoo ntawm cov wafer.

Cov txiaj ntsig tau pom tias nrog kev nce qib ntawm cov txheej txheem ua tiav, qhov saum npoo morphology thiab roughness ntawm wafer tau maj mam optimized. Tom qab polishing, roughness ntawm C-lub ntsej muag thiab Si-face ncav cuag 0.24nm thiab 0.14nm feem, uas ua tau raws li qhov yuav tsum tau ntawm kev loj hlob epitaxial. C-lub ntsej muag ntawm wafer muaj qhov tsis zoo dua li cov khoom siv Si-ntsej muag, thiab muaj kev cuam tshuam ntau dua rau cov pob txha tawg thaum ua haujlwm, ua rau qhov tsis zoo ntawm qhov chaw morphology thiab roughness. Tshem tawm cov txheej txheej puas ntawm cov txheej txheem ua tiav yog tus yuam sij rau kev txhim kho qhov zoo ntawm lub wafer. Qhov ib nrab-dav ntawm 4H-SiC (0004) rocking nkhaus tuaj yeem intuitively thiab raug tus yam ntxwv ntawm txheej txheej ntawm lub wafer.

Kev tshawb fawb qhia tau hais tias cov txheej puas rau ntawm qhov chaw ntawm 4H-SiC wafers yuav maj mam tshem tawm los ntawm 4H-SiC wafer ua, zoo txhim kho qhov zoo ntawm lub wafer, muab cov kev siv rau high-efficiency, tsawg-poob, thiab high- Kev ua haujlwm zoo ntawm 4H-SiC substrate wafers.

Lub sij hawm xa tuaj: Plaub Hlis-08-2024