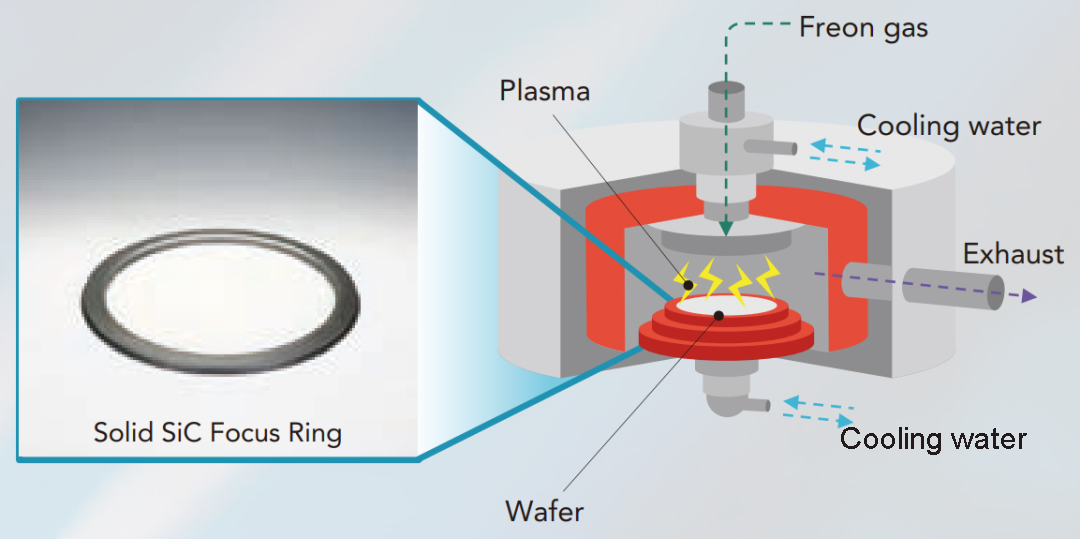

Hauv cov khoom siv plasma etching, cov khoom siv ceramic ua lub luag haujlwm tseem ceeb, suav nrogtsom nplhaib.Cov tsom nplhaib, muab tso rau ib ncig ntawm lub wafer thiab nyob rau hauv kev sib cuag ncaj qha nrog nws, yog ib qho tseem ceeb rau tsom lub plasma mus rau lub wafer los ntawm kev thov voltage rau lub nplhaib. Qhov no txhim kho cov uniformity ntawm cov txheej txheem etching.

Daim ntawv thov ntawm SiC Focus Rings hauv Etching Machine

SiC CVD Cheebtsamhauv etching tshuab, xws litsom rings, gas da dej, platens, thiab ntug rings, tau txais txiaj ntsig vim SiC qhov tsis tshua muaj kev cuam tshuam nrog cov tshuaj chlorine thiab fluorine-based etching gases thiab nws cov conductivity, ua rau nws yog ib qho khoom siv zoo tshaj plaws rau cov khoom siv plasma etching.

Qhov zoo ntawm SiC ua lub nplhaib tsom iav

Vim qhov ncaj qha raug rau cov ntshav hauv lub tshuab nqus tsev cov tshuaj tiv thaiv chamber, tsom rings yuav tsum tau ua los ntawm cov ntaub ntawv plasma-resistant. Ib txwm tsom rings, ua los ntawm silicon los yog quartz, raug kev txom nyem los ntawm tsis zoo etching kuj nyob rau hauv fluorine-raws li plasmas, ua rau kom ceev corrosion thiab txo efficiency.

Sib piv ntawm Si thiab CVD SiC Focus Rings:

1. Higher Density:Txo etching ntim.

2. Wide Bandgap: Muab cov rwb thaiv tsev zoo heev.

3. High Thermal Conductivity & Tsawg Expansion Coefficient: Resistant rau thermal shock.

4. High Elasticity:Zoo tsis kam rau txhua yam cuam tshuam.

5. High Hardness: Hnav thiab corrosion-resistant.

SiC sib koom silicon cov hluav taws xob conductivity thaum muab kev tiv thaiv zoo rau ionic etching. Raws li kev sib xyaw ua ke ntawm miniaturization zuj zus, qhov kev thov rau cov txheej txheem etching muaj txiaj ntsig ntau ntxiv. Cov cuab yeej siv plasma etching, tshwj xeeb tshaj yog cov uas siv capacitive coupled plasma (CCP), yuav tsum tau muaj zog plasma siab, uaSiC tsom ringsnrov zuj zus.

Si thiab CVD SiC Focus Ring Parameters:

| Parameter | Silicon (Si) | Tom ntej: CVD Silicon Carbide (SiC) |

| Qhov ceev (g / cm³) | 2.33 ib | 3.21 |

| Band Gap (eV) | 1.12 | 2.3 |

| Thermal conductivity (W / cm ° C) | 1.5 | 5 |

| Thermal Expansion Coefficient (x10⁻⁶/°C) | 2.6 | 4 |

| Elastic Modulus (GPa) | 150 | 440 |

| Hardness | qis | Siab dua |

Kev tsim cov txheej txheem ntawm SiC Focus Rings

Hauv cov khoom siv semiconductor, CVD (Chemical Vapor Deposition) feem ntau yog siv los tsim cov khoom siv SiC. Lub nplhaib tsom iav yog tsim los ntawm kev tso SiC rau hauv cov duab tshwj xeeb los ntawm vapor deposition, ua raws li kev siv tshuab los ua cov khoom kawg. Cov khoom sib piv rau vapor deposition yog tsau tom qab nws kim heev kev sim, ua tsis xws li resistivity zoo ib yam. Txawm li cas los xij, cov khoom sib txawv etching tej zaum yuav xav tau cov nplhaib uas muaj qhov sib txawv ntawm qhov sib txawv, xav tau cov khoom siv tshiab piv rau txhua qhov tshwj xeeb, uas yog siv sijhawm ntev thiab kim.

Los ntawm kev xaivSiC tsom ringslos ntawmSemiconductor, cov neeg siv khoom tuaj yeem ua tiav cov txiaj ntsig ntawm kev hloov mus ntev dua thiab kev ua haujlwm zoo dua yam tsis muaj kev nce nqi ntau.

Rapid Thermal Processing (RTP) Cheebtsam

CVD SiC qhov tshwj xeeb thermal zog ua rau nws zoo tagnrho rau RTP daim ntawv thov. RTP Cheebtsam, suav nrog ntug rings thiab platens, tau txais txiaj ntsig los ntawm CVD SiC. Thaum lub sij hawm RTP, khaus khaus pulses yog siv rau ib tug neeg wafers rau lub sij hawm luv luv, ua raws li los ntawm ceev ceev. CVD SiC ntug rings, ua nyias thiab tsis tshua muaj thermal mass, tsis khaws cov cua kub tseem ceeb, ua rau lawv tsis muaj kev cuam tshuam los ntawm cov cua kub ceev thiab cua txias.

Plasma Etching Cheebtsam

CVD SiC cov tshuaj tiv thaiv siab ua rau nws haum rau etching daim ntaub ntawv. Ntau lub etching chamber siv CVD SiC roj faib daim hlau los faib cov roj etching, muaj ntau txhiab qhov me me rau cov ntshav plasma dispersion. Piv nrog rau lwm cov ntaub ntawv, CVD SiC muaj qhov qis dua nrog cov tshuaj chlorine thiab fluorine gases. Nyob rau hauv qhuav etching, CVD SiC Cheebtsam xws li tsom rings, ICP platens, ciam rings, thiab da dej hau yog feem ntau siv.

SiC tsom rings, nrog rau lawv cov voltage thov rau plasma tsom, yuav tsum muaj txaus conductivity. Feem ntau ua los ntawm silicon, tsom rings raug rau reactive gases uas muaj fluorine thiab chlorine, ua rau inevitable corrosion. SiC tsom rings, nrog rau lawv superior corrosion kuj, muaj lifespans ntev dua piv rau silicon rings.

Kev sib piv Lifecycle:

· SiC Focus Rings:Hloov txhua 15 mus rau 20 hnub.

· Silicon Focus Rings:Hloov txhua 10 mus rau 12 hnub.

Txawm hais tias SiC rings yog 2 mus rau 3 lub sij hawm kim dua silicon rings, ncua sij hawm hloov lub voj voog txo cov nqi hloov tag nrho, vim tias tag nrho cov khoom hnav hauv lub chamber raug hloov ib txhij thaum lub chamber qhib rau kev hloov lub nplhaib.

Semicera Semiconductor's SiC Focus Rings

Semicera Semiconductor muab SiC tsom rings ntawm tus nqi ze rau cov ntawm silicon rings, nrog rau lub sij hawm ua tus coj ntawm kwv yees li 30 hnub. Los ntawm kev sib koom ua ke ntawm Semicera's SiC tsom rings rau hauv cov khoom siv plasma etching, kev ua tau zoo thiab kev ua haujlwm ntev tau txhim kho, txo cov nqi kho tag nrho thiab txhim kho kev tsim khoom. Tsis tas li ntawd, Semicera tuaj yeem hloov kho qhov kev tiv thaiv ntawm lub nplhaib tsom kom tau raws li cov neeg siv khoom tshwj xeeb.

Los ntawm kev xaiv SiC tsom rings los ntawm Semicera Semiconductor, cov neeg siv khoom tuaj yeem ua tiav cov txiaj ntsig ntawm kev hloov mus ntev dua thiab kev ua tau zoo dua yam tsis muaj tus nqi nce ntxiv.

Post lub sij hawm: Lub Xya hli ntuj-10-2024