[Cov ntsiab lus piav qhia] Atmospheric siab sinteredsilicon carbideyog ib qho uas tsis yog-metallic carbide ua ke nrog silicon thiab carbon covalent bonds, thiab nws hardness yog thib ob tsuas yog pob zeb diamond thiab boron carbide. Cov tshuaj formula yog SiC. Cov xim tsis muaj xim, xiav thiab dub nyob rau hauv tsos thaum oxidized los yog muaj impurities.

Atmospheric siab sinteredsilicon carbideyog ib qho uas tsis yog-metallic carbide nrog silicon thiab carbon covalent daim ntawv cog lus, thiab nws hardness yog thib ob tsuas yog pob zeb diamond thiab boron carbide. Cov tshuaj formula yog SiC. Cov xim tsis muaj kob, xiav thiab dub nyob rau hauv tsos thaum oxidized los yog muaj impurities. Lub deformation ntawmsilicon carbidenrog pob zeb diamond qauv feem ntau hu ua emery. Lub hardness ntawm emery yog ze rau pob zeb diamond, zoo thermal stability, ruaj khov rau hydroxy acid aqueous tov thiab concentrated sulfuric acid, thiab tsis ruaj tsis khov rau cov kua qaub tov los yog phosphoric acid ntawm concentrated hydrogen acid thiab nitric acid. Alkalis uas yaj hauv qhov chaw hollow sib txawv. Nws muab faib ua hluavtawssilicon carbidethiab natural silicon carbide. Ntuj silicon carbide, hu ua carbonite, feem ntau pom nyob rau hauv kimberlite thiab volcanic amphibolite, tab sis nws cov nyiaj yog me me thiab tsis muaj nqi excavation.

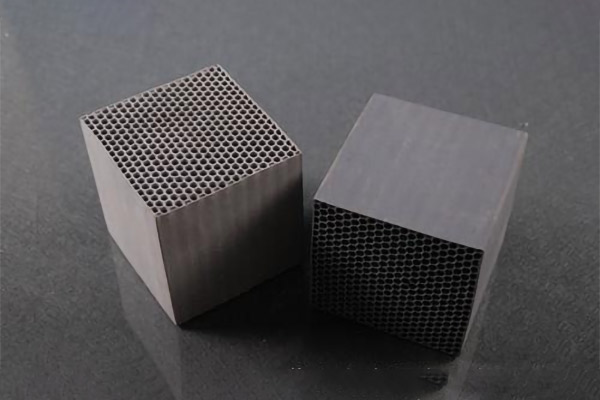

Industrial atmospheric siab sinteredsilicon carbideyog ib tug sib tov ntawm -SiC thiab -SiC thiab tuaj nyob rau hauv ob xim: dub thiab ntsuab. Ntshiab silicon carbide tsis muaj xim, muaj impurities yog dub, ntsuab, xiav, daj. Hexagonal thiab cubic grain ciam teb, cov siv lead ua yog phaj, compound kem. iav luster, ntom 3.17-3.47G / CM3, Morse hardness 9.2, lub tshuab tsom xam kuj ntawm 30380 ~ 33320MPa melting point: atmospheric 2050 pib sib txawv, rov qab cua 2600 pib sib txawv. Lub elastic coefficient yog 466, 480MPa. Lub zog tensile yog 171.5MPa. Lub zog compressive yog 1029MPa. Lub linear expansion coefficient yog (25 ~ 1000) 5.010 ~ 6 /, thiab thermal conductivity (20) yog 59w / (mk). Tshuaj stability, boiling nyob rau hauv HCI, H2SO4, HF yuav tsis erode.

Raws li kev siv sib txawv, atmospheric siab sintered silicon carbide muab faib ua abrasive, refractory cov ntaub ntawv, deoxidizer, hluav taws xob silicon carbide thiab lwm yam. SiC cov ntsiab lus ntawm abrasive silicon carbide yuav tsum tsis txhob tsawg dua 98%. Refractories nrog silicon carbide tau muab faib ua: (1) cov ntaub ntawv siab heev refractory dub silicon carbide, nws cov ntsiab lus SiC yog tib yam li kev sib tsoo silicon carbide. (2) Cov ntaub ntawv thib ob refractory dub silicon carbide, SiC cov ntsiab lus ntau dua 90%. (3) Cov ntsiab lus ntawm cov dub silicon carbide thiab SiC hauv cov qib qis refractories tsis tsawg dua 83%. Cov ntsiab lus ntawm silicon carbide thiab SiC siv hauv deoxidizer feem ntau yuav tsum tau siab dua 90%. Txawm li cas los xij, carbon industrial graphitization furnace rwb thaiv tsev, silicon carbide cov ntsiab lus ntawm ntau tshaj 45% ntawm kev kho mob kuj tseem siv tau los ua steelmaking deoxidizer. Silicon carbide rau deoxidizing tus neeg sawv cev muaj ob hom hmoov zoo thiab molding thaiv. Hmoov deoxidizer dub silicon carbide feem ntau muaj qhov loj me ntawm 4 ~ 0.5 hli thiab 0.5 ~ 0.1 hli. Hluav taws xob siv hluav taws xob silicon carbide muaj ob pawg loj. (1) Ntsuab silicon carbide siv rau hluav taws xob cua sov ntsiab lus tseem ceeb tib yam li ntsuab silicon carbide siv rau kev sib tsoo. (2) Silicon carbide rau cov neeg ntes tau tshwj xeeb cov khoom siv hluav taws xob, uas txawv ntawm cov xim dub silicon carbide rau kev sib tsoo cov ntaub ntawv refractory.

Kev siv atmospheric siab sintered silicon carbide

Atmospheric siab sintered silicon carbide cov khoom muaj kev ua haujlwm tshwj xeeb xws li kub tsis kam, hnav tsis kam, kub tsis kam, hluav taws kub tsis kam, hluav taws xob tiv thaiv, hluav taws xob zoo heev thiab thermal conductivity, thiab lwm yam, thiab tau siv dav hauv ntau lub tuam tsev ntawm kev lag luam hauv teb chaws. Hauv Suav teb, ntsuab silicon carbide feem ntau yog siv los ua abrasive. Dub silicon carbide yog siv los ua cov pob zeb sib tsoo, uas feem ntau yog siv los txiav thiab zom cov ntaub ntawv uas tsis muaj zog tensile, xws li iav, ceramics, pob zeb, refractories, thiab tseem siv rau kev sib tsoo cam khwb cia hlau qhov chaw thiab cov ntaub ntawv tsis yog hlau. Kev sib tsoo ua los ntawm ntsuab silicon carbide feem ntau yog siv rau kev sib tsoo ntawm cemented carbide, titanium alloy, kho qhov muag iav, thiab kuj rau kev sib tsoo ntawm lub tog raj kheej liner thiab cov cuab yeej siv hlau ceev. Cubic silicon carbide abrasives tsuas yog siv rau ultra-precision sib tsoo ntawm cov kabmob me me. Kev hnav tsis kam ntawm turbine impellers tuaj yeem txhim kho tau zoo los ntawm kev siv SIC hmoov rau lawv los ntawm electroplating. Siv cov cuab yeej siv siab los thawb lub cubic SiC200 zeb thiab W28 micro-hmoov mus rau lub tog raj kheej phab ntsa ntawm lub tshuab hluav taws xob sab hauv, lub tog raj kheej lub neej tuaj yeem ua tau ntau dua ob npaug.

Post lub sij hawm: Oct-11-2023