Silicon carbide (SiC) substrates muaj ntau yam tsis xws luag uas tiv thaiv kev ua haujlwm ncaj qha. Txhawm rau tsim cov chips wafers, ib zaj duab xis ib leeg yuav tsum tau cog rau ntawm SiC substrate los ntawm cov txheej txheem epitaxial. Zaj duab xis no yog hu ua epitaxial txheej. Yuav luag tag nrho cov khoom siv SiC tau paub txog ntawm cov ntaub ntawv epitaxial, thiab cov ntaub ntawv zoo homoepitaxial SiC tsim lub hauv paus rau kev txhim kho SiC. Kev ua tau zoo ntawm cov ntaub ntawv epitaxial ncaj qha txiav txim siab ua haujlwm ntawm SiC li.

Cov cuab yeej siv siab tam sim no thiab kev ntseeg siab SiC tsim cov kev cai nruj ntawm qhov chaw morphology, qhov tsis xws luag, doping uniformity, thiab thickness uniformity ntawmepitaxialcov ntaub ntawv. Ua tiav qhov loj-loj, tsis muaj qhov tsis xws luag, thiab siab sib xws SiC epitaxy tau dhau los ua qhov tseem ceeb rau kev txhim kho ntawm SiC kev lag luam.

Ua tau zoo SiC epitaxy cia siab rau cov txheej txheem thiab cov cuab yeej siv siab heev. Tam sim no, txoj kev siv dav tshaj plaws rau SiC epitaxial kev loj hlob yogChemical Vapor Deposition (CVD).CVD muaj kev tswj xyuas meej ntawm epitaxial zaj duab xis tuab thiab doping concentration, tsis muaj qhov tsis xws luag, kev loj hlob nruab nrab, thiab kev tswj cov txheej txheem, ua rau nws muaj kev ntseeg siab rau kev lag luam kev lag luam.

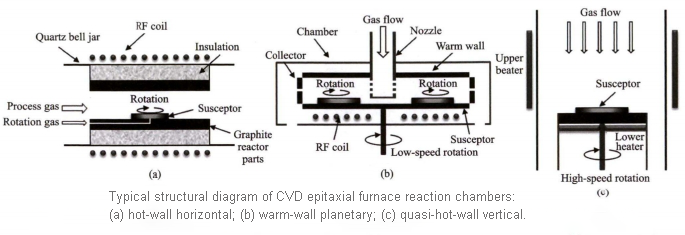

SiC CVD epitaxyFeem ntau siv cov khoom siv kub-phab ntsa lossis sov-phab ntsa CVD. Kev loj hlob kub (1500-1700 ° C) ua kom muaj kev txuas ntxiv ntawm 4H-SiC crystalline daim ntawv. Raws li kev sib raug zoo ntawm cov roj ntws cov kev taw qhia thiab lub substrate nto, cov tshuaj tiv thaiv chav ntawm cov CVD systems yuav muab faib mus rau hauv kab rov tav thiab ntsug.

Qhov zoo ntawm SiC epitaxial furnaces yog txiav txim los ntawm peb yam: epitaxial kev loj hlob kev ua tau zoo (xws li thickness uniformity, doping uniformity, tsis xws luag, thiab loj hlob tus nqi), kub kev ua tau zoo ntawm cov cuab yeej (xws li cua sov / cua txias tus nqi, siab tshaj plaws kub, thiab kub uniformity. ), thiab tus nqi-zoo (nrog rau cov nqi tsev thiab cov peev txheej ntau lawm).

Qhov sib txawv ntawm peb hom SiC Epitaxial Growth Rauv

1.Hot-wall Kab rov tav CVD Systems:

-Nta:Feem ntau feature ib leeg-wafer loj-loj-loj-loj hlob tshuab tsav los ntawm roj floatation rotation, ua tau zoo heev intra-wafer metrics.

-Tus Neeg Sawv Cev Qauv:LPE's Pe1O6, muaj peev xwm ntawm automated wafer loading / unloading ntawm 900 ° C. Paub txog kev loj hlob siab, luv luv epitaxial cycles, thiab zoo ib yam intra-wafer thiab inter-khiav kev ua tau zoo.

-Kev ua tau zoo:Rau 4-6 nti 4H-SiC epitaxial wafers nrog thickness ≤30μm, nws ua tiav intra-wafer thickness non-uniformity ≤2%, doping concentration non-uniformity ≤5%, defect defect ntom ≤1 cm-², thiab tsis xws luag thaj chaw saum npoo (2mm × 2mm hlwb) ≥90%.

-Cov neeg tsim khoom hauv tsev: Cov tuam txhab xws li Jingsheng Mechatronics, CETC 48, North Huachuang, thiab Nasset Intelligent tau tsim cov cuab yeej zoo sib xws SiC epitaxial ib leeg nrog cov khoom tsim tawm.

2. Warm-wall Planetary CVD Systems:

-Nta:Siv lub hauv paus kev npaj rau lub hauv paus rau kev loj hlob ntawm ntau wafer ib batch, txhim kho cov txiaj ntsig zoo.

-Cov Qauv Sawv Cev:Aixtron's AIXG5WWC (8x150mm) thiab G10-SiC (9x150mm lossis 6x200mm) series.

-Kev ua tau zoo:Rau 6-nti 4H-SiC epitaxial wafers nrog thickness ≤10μm, nws ua tiav inter-wafer thickness sib txawv ± 2.5%, intra-wafer thickness non-uniformity 2%, inter-wafer doping concentration sib txawv ± 5%, thiab intra-wafer doping concentration tsis sib xws <2%.

-Kev sib tw:Kev txwv tsis pub siv rau hauv kev lag luam hauv tsev vim tsis muaj cov ntaub ntawv tsim khoom ntau lawm, kev cuam tshuam hauv kev ntsuas kub thiab dej ntws, thiab R&D txuas ntxiv yam tsis muaj kev siv loj.

3. Quasi-kub-wall Vertical CVD Systems:

- Nta:Siv cov cuab yeej siv sab nraud rau kev sib hloov ntawm cov substrate high-speed substrate, txo ciam txheej thickness thiab txhim kho epitaxial kev loj hlob tus nqi, nrog inherent zoo hauv kev tswj tsis xws luag.

- Cov Qauv Sawv Cev:Nuflare's single-wafer EPIREVOS6 thiab EPIREVOS8.

-Kev ua tau zoo:Ua tiav qhov kev loj hlob ntau tshaj 50μm / h, deg defect ceev tswj hauv qab 0.1 cm-², thiab intra-wafer thickness thiab doping concentration non-uniformity ntawm 1% thiab 2.6%, feem.

-Kev txhim kho hauv tsev:Cov tuam txhab xws li Xingsandai thiab Jingsheng Mechatronics tau tsim cov cuab yeej zoo sib xws tab sis tsis tau ua tiav kev siv loj.

Cov ntsiab lus

Txhua yam ntawm peb hom qauv ntawm SiC epitaxial kev loj hlob cov cuab yeej muaj cov yam ntxwv sib txawv thiab tuav cov lag luam tshwj xeeb raws li cov ntawv thov. Kub-phab ntsa kab rov tav CVD muaj kev loj hlob sai heev thiab sib npaug zoo thiab sib xws tab sis muaj kev ua haujlwm qis dua vim kev ua haujlwm ib leeg. Sov-phab ntsa planetary CVD ho txhim kho kev tsim khoom tab sis ntsib cov teeb meem hauv kev tswj ntau qhov sib xws. Quasi-kub-phab ntsa ntsug CVD ua tau zoo hauv kev tswj tsis raug nrog cov qauv nyuaj thiab xav tau kev saib xyuas thiab kev ua haujlwm ntau.

Raws li kev lag luam hloov zuj zus mus, kev ua kom zoo dua qub thiab hloov kho dua tshiab hauv cov cuab yeej siv no yuav ua rau muaj kev txhim kho ntxiv, ua si lub luag haujlwm tseem ceeb hauv kev ua kom tau raws li ntau haiv neeg epitaxial wafer specifications rau thickness thiab tsis xws luag.

Qhov zoo thiab qhov tsis zoo ntawm qhov sib txawv SiC Epitaxial Growth Rauv

| Rauv hom | Qhov zoo | Qhov tsis zoo | Cov neeg sawv cev ntawm cov neeg tsim khoom |

| Kub-wall Kab rov tav CVD | Kev loj hlob sai, qauv yooj yim, kev saib xyuas yooj yim | Lub voj voog tu ncua luv | LPE (Ltalis), TEL (Nyiv) |

| Warm-wall Planetary CVD | Muaj peev xwm ntau lawm, ua haujlwm tau zoo | Cov qauv tsis yooj yim, kev tswj tsis tau yooj yim | Aixtron (Lub teb chaws Yelemees) |

| Quasi-hot-wall Vertical CVD | Kev tswj tsis raug zoo heev, lub sijhawm ua haujlwm ntev | Complex qauv, yooj yim los tswj | Nuflare (Nyiv) |

Nrog rau kev txhim kho kev lag luam tas mus li, peb hom khoom siv no yuav ua kom zoo dua qub thiab hloov kho dua tshiab, ua rau muaj kev txhim kho ntxiv uas haum rau ntau yam epitaxial wafer specifications rau thickness thiab tsis xws luag.

Post lub sij hawm: Lub Xya hli ntuj-19-2024