Kev loj hlob sai ntawm SiC Tib Crystal SivCVD-SiC BulkTau qhov twg los ntawm Sublimation Method

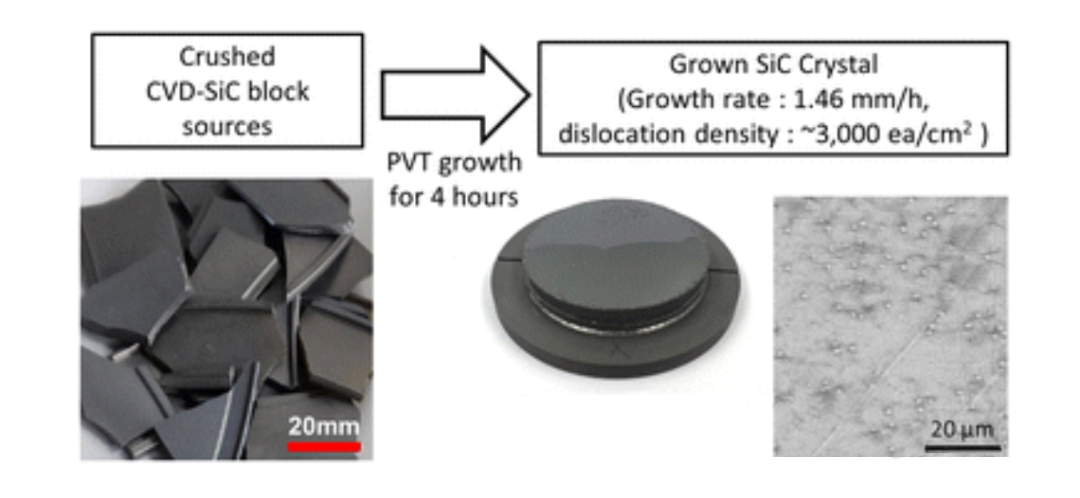

Los ntawm kev siv rov ua duaCVD-SiC blocksRaws li SiC qhov chaw, SiC crystals tau ua tiav ntawm tus nqi ntawm 1.46 mm / h los ntawm txoj kev PVT. Cov loj hlob siv lead ua lub micropipe thiab dislocation densities qhia tias txawm tias qhov kev loj hlob siab, cov khoom siv lead ua zoo heev.

Silicon carbide (SiC)yog qhov dav-bandgap semiconductor nrog cov khoom zoo heev rau kev siv hauv high voltage, siab zog, thiab siab zaus. Nws qhov kev thov tau loj hlob sai nyob rau xyoo tas los no, tshwj xeeb tshaj yog nyob rau hauv lub zog semiconductor teb. Rau kev siv hluav taws xob semiconductor, SiC ib leeg muaju yog loj hlob los ntawm sublimating high-purity SiC qhov chaw ntawm 2100-2500 ° C, ces recrystallizing rau cov noob siv lead ua siv lub cev vapor thauj (PVT) txoj kev, ua raws li kev ua kom tau ib qho siv lead ua substrates ntawm wafers. . Kev lig kev cai,SiC siv lead uayog zus siv PVT txoj kev ntawm kev loj hlob ntawm 0.3 mus rau 0.8 mm / h los tswj crystallinity, uas yog qeeb piv rau lwm yam siv lead ua siv lead ua siv nyob rau hauv semiconductor daim ntaub ntawv. Thaum SiC crystals loj hlob ntawm kev loj hlob siab siv txoj kev PVT, kev degradation zoo nrog rau cov pa roj carbon inclusions, txo purity, polycrystalline kev loj hlob, grain ciam teb tsim, thiab dislocation thiab porosity defects tsis tau txiav txim. Yog li ntawd, kev loj hlob sai ntawm SiC tsis tau tsim, thiab kev loj hlob qeeb ntawm SiC tau ua ib qho teeb meem loj rau kev tsim khoom ntawm SiC substrates.

Ntawm qhov tod tes, tsis ntev los no cov ntaub ntawv qhia txog kev loj hlob sai ntawm SiC tau siv cov txheej txheem kub kub chemical vapor deposition (HTCVD) es tsis yog PVT txoj kev. Txoj kev HTCVD siv lub vapor uas muaj Si thiab C raws li SiC qhov chaw hauv reactor. HTCVD tseem tsis tau siv rau kev tsim khoom loj ntawm SiC thiab xav tau kev tshawb fawb ntxiv thiab kev txhim kho rau kev lag luam. Interestingly, txawm nyob rau ntawm qhov loj hlob ntawm ∼ 3 mm / h, SiC ib leeg muaju tuaj yeem loj hlob nrog cov siv lead ua zoo siv txoj kev HTCVD. Lub caij no, SiC Cheebtsam tau siv rau hauv cov txheej txheem semiconductor nyob rau hauv ib puag ncig hnyav uas yuav tsum tau tswj cov txheej txheem purity siab heev. Rau cov txheej txheem semiconductor, ∼99.9999% (∼6N) purity SiC Cheebtsam feem ntau yog npaj los ntawm CVD txheej txheem los ntawm methyltrichlorosilane (CH3Cl3Si, MTS). Txawm li cas los xij, txawm hais tias qhov siab purity ntawm CVD-SiC Cheebtsam, lawv tau muab pov tseg tom qab siv. Tsis ntev los no, pov tseg CVD-SiC Cheebtsam tau raug suav tias yog SiC qhov chaw rau kev loj hlob siv lead ua, txawm hais tias qee qhov txheej txheem rov qab los suav nrog kev crushing thiab purification tseem yuav tsum tau ua kom tau raws li qhov xav tau ntawm cov khoom siv lead ua loj hlob. Nyob rau hauv txoj kev tshawb no, peb tau muab pov tseg CVD-SiC blocks los siv cov ntaub ntawv los ua ib qhov chaw loj hlob SiC crystals. CVD-SiC blocks rau ib qho kev loj hlob siv lead ua tau npaj raws li qhov loj-tswj crushed blocks, sib txawv hauv cov duab thiab qhov loj me piv rau kev lag luam SiC hmoov feem ntau siv hauv cov txheej txheem PVT, yog li tus cwj pwm ntawm SiC ib leeg siv lead ua kev loj hlob tau xav tias yuav muaj txiaj ntsig zoo. txawv. Ua ntej ua SiC ib qho kev loj hlob siv lead ua thwmsim, computer simulations tau ua kom ua tiav qhov kev loj hlob siab, thiab thaj chaw thermal tau teeb tsa raws li kev loj hlob ib leeg. Tom qab siv lead ua kev loj hlob, cov pob zeb loj hlob tau raug soj ntsuam los ntawm kev sib tshuam tomography, micro-Raman spectroscopy, high-resolution X-ray diffraction, thiab synchrotron dawb beam X-ray topography.

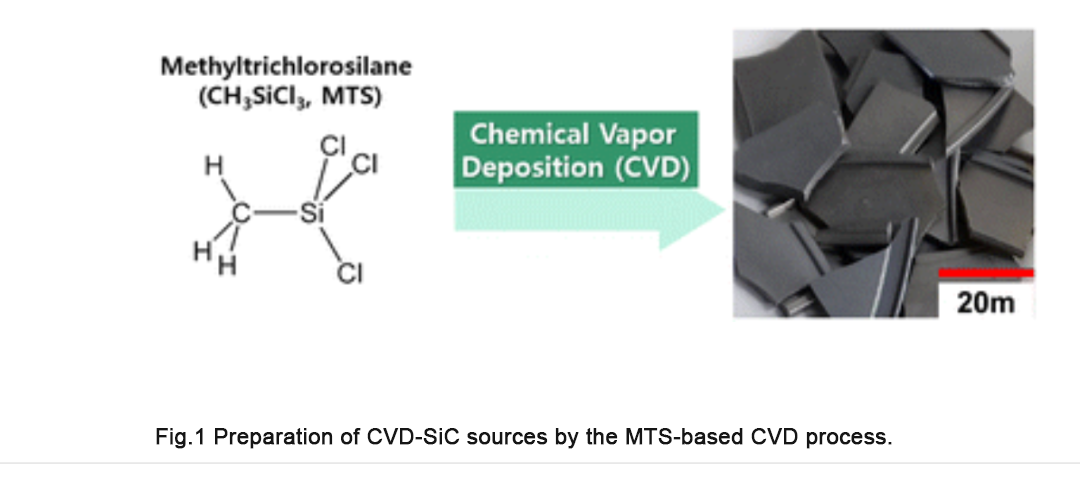

Daim duab 1 qhia txog CVD-SiC qhov chaw siv rau PVT kev loj hlob ntawm SiC crystals hauv txoj kev tshawb no. Raws li tau piav qhia hauv kev taw qhia, CVD-SiC Cheebtsam tau tsim los ntawm MTS los ntawm cov txheej txheem CVD thiab zoo li tus siv rau semiconductor siv los ntawm kev ua tshuab. N tau doped nyob rau hauv CVD txheej txheem kom ua tiav conductivity rau semiconductor txheej txheem kev siv. Tom qab siv rau hauv cov txheej txheem semiconductor, CVD-SiC cov khoom raug crushed los npaj qhov chaw rau kev loj hlob siv lead ua, raws li qhia hauv daim duab 1. Lub CVD-SiC qhov chaw tau npaj ua cov phaj nrog qhov nruab nrab tuab ntawm ∼0.5 hli thiab qhov nruab nrab particle loj ntawm 49.75mm ib.

Daim duab 1: CVD-SiC qhov chaw npaj los ntawm MTS-raws li CVD txheej txheem.

Daim duab 1: CVD-SiC qhov chaw npaj los ntawm MTS-raws li CVD txheej txheem.

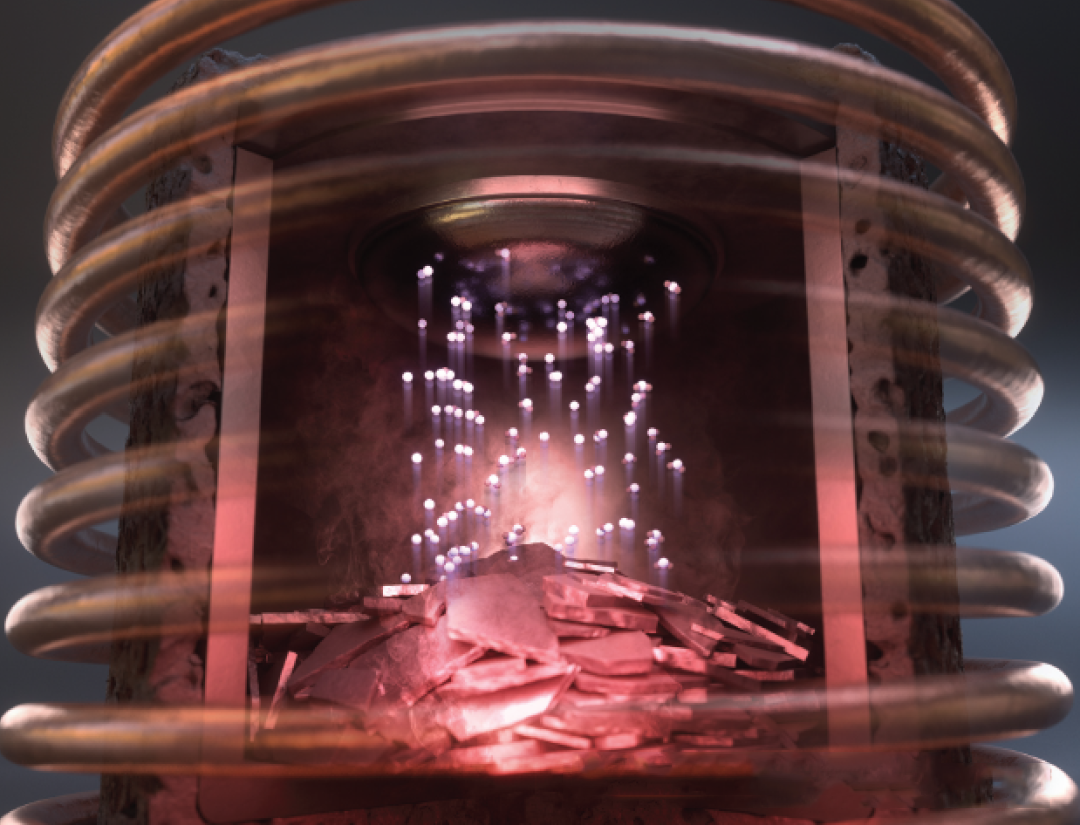

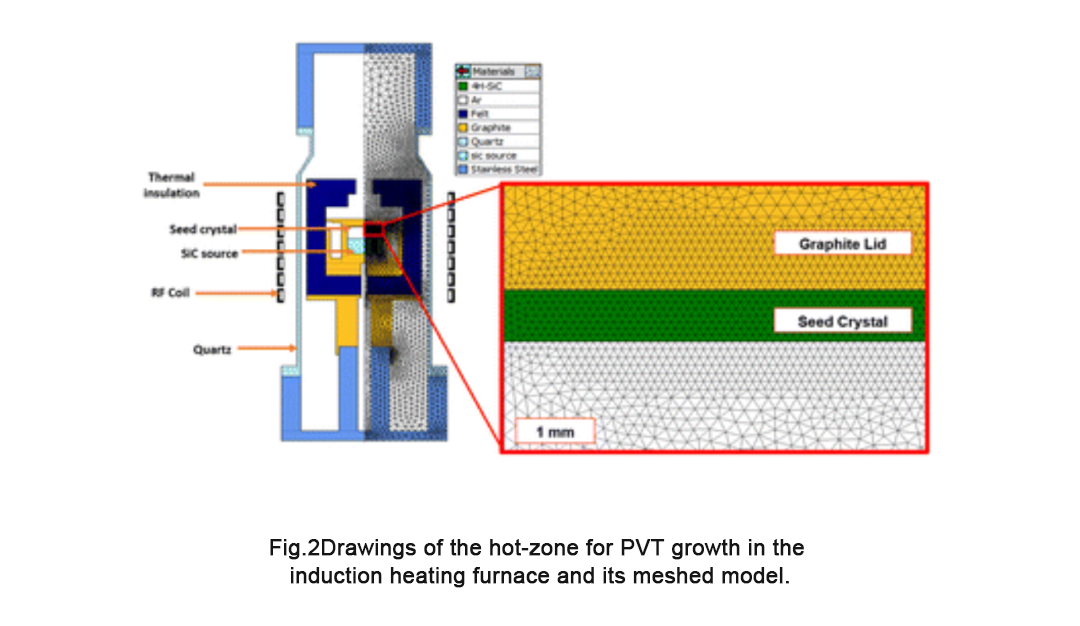

Siv CVD-SiC qhov chaw qhia hauv daim duab 1, SiC muaju tau loj hlob los ntawm PVT txoj hauv kev induction cua sov rauv. Txhawm rau ntsuas qhov kub thiab txias hauv cheeb tsam thermal, kev lag luam simulation code VR-PVT 8.2 (STR, Republic of Serbia) tau siv. Lub reactor nrog lub thermal cheeb tsam tau ua qauv raws li 2D axisymmetric qauv, raws li qhia hauv daim duab 2, nrog nws cov qauv mesh. Tag nrho cov ntaub ntawv siv nyob rau hauv lub simulation yog qhia nyob rau hauv daim duab 2, thiab lawv cov khoom muaj npe nyob rau hauv Table 1. Raws li cov simulation tshwm sim, SiC crystals tau loj hlob siv txoj kev PVT ntawm qhov kub thiab txias ntawm 2250-2350 ° C nyob rau hauv ib qho chaw Ar. 35 Torr rau 4 teev. A 4 ° tawm-axis 4H-SiC wafer tau siv los ua SiC noob. Cov pob zeb loj hlob tau raug soj ntsuam los ntawm micro-Raman spectroscopy (Witec, UHTS 300, Lub teb chaws Yelemees) thiab kev daws teeb meem siab XRD (HRXRD, X'Pert-PROMED, PANalytical, Netherlands). Cov impurity concentrations nyob rau hauv zus SiC crystals raug soj ntsuam siv dynamic theem nrab ion huab hwm coj spectrometry (SIMS, Cameca IMS-6f, Fabkis). Lub dislocation ceev ntawm cov noob qoob loo tau soj ntsuam siv synchrotron dawb beam X-ray topography ntawm Pohang Light Source.

Daim duab 2: Daim duab tshav kub thiab mesh qauv ntawm PVT kev loj hlob nyob rau hauv ib qho induction cua sov rauv.

Daim duab 2: Daim duab tshav kub thiab mesh qauv ntawm PVT kev loj hlob nyob rau hauv ib qho induction cua sov rauv.

Txij li HTCVD thiab PVT txoj kev loj hlob muaju nyob rau hauv cov roj-khoom sib npaug ntawm qhov kev loj hlob pem hauv ntej, kev loj hlob sai ntawm SiC los ntawm HTCVD txoj kev ua rau muaj kev sib tw ntawm kev loj hlob sai ntawm SiC los ntawm PVT txoj kev tshawb no. Txoj kev HTCVD siv cov roj av uas yooj yim khiav-tswj, thaum PVT txoj kev siv cov khoom siv uas tsis ncaj qha tswj kev ntws. Tus nqi ntws tau muab rau kev loj hlob pem hauv ntej hauv PVT txoj kev tuaj yeem tswj tau los ntawm sublimation tus nqi ntawm cov khoom siv los ntawm kev tswj qhov kub thiab txias, tab sis kev tswj xyuas qhov kub thiab txias hauv cov txheej txheem kev loj hlob tsis yooj yim rau kev ua tiav.

Los ntawm kev nce qhov kub thiab txias hauv PVT reactor, qhov kev loj hlob ntawm SiC tuaj yeem nce ntxiv los ntawm kev nce sublimation tus nqi ntawm qhov chaw. Yuav kom ua tiav qhov kev loj hlob ruaj khov siv lead ua, kev tswj kub ntawm kev loj hlob pem hauv ntej yog qhov tseem ceeb heev. Txhawm rau nce qhov kev loj hlob yam tsis tau tsim polycrystals, qhov kub-kub gradient yuav tsum tau ua tiav ntawm kev loj hlob pem hauv ntej, raws li qhia los ntawm SiC kev loj hlob ntawm HTCVD txoj kev. Tsis zoo ntsug cua sov conduction mus rau sab nraum qab ntawm lub hau yuav tsum dissipate cov cua kub nyob rau hauv kev loj hlob pem hauv ntej los ntawm thermal tawg mus rau qhov loj hlob nto, ua rau cov tsim ntawm ntau tshaj qhov chaw, piv txwv li, polycrystalline kev loj hlob.

Ob qhov kev hloov pauv loj thiab cov txheej txheem recrystallization hauv PVT txoj kev zoo ib yam li HTCVD txoj kev, txawm hais tias lawv txawv ntawm SiC qhov chaw. Qhov no txhais tau hais tias kev loj hlob sai ntawm SiC kuj tseem ua tiav thaum lub sublimation tus nqi ntawm SiC qhov siab txaus. Txawm li cas los xij, kev ua tiav zoo SiC ib leeg siv lead ua nyob rau hauv cov xwm txheej loj hlob ntawm PVT txoj kev muaj ntau qhov kev sib tw. Cov hmoov ua lag luam feem ntau muaj kev sib xyaw ntawm cov khoom me me thiab loj. Vim yog qhov sib txawv ntawm lub zog ntawm qhov sib txawv, cov khoom me me muaj qhov siab impurity concentrations thiab sublimate ua ntej cov khoom loj, ua rau cov impurity siab nyob rau hauv cov theem pib loj hlob ntawm cov siv lead ua. Tsis tas li ntawd, raws li cov khoom SiC decomposes rau hauv vapor hom xws li C thiab Si, SiC2 thiab Si2C ntawm qhov kub thiab txias, khoom C inevitably tsim thaum SiC qhov sublimates hauv PVT txoj kev. Yog tias cov khoom tsim C me me thiab lub teeb txaus, nyob rau hauv cov xwm txheej loj hlob sai, cov C me me, hu ua "C plua plav," tuaj yeem thauj mus rau cov khoom siv lead ua los ntawm kev hloov pauv loj, uas ua rau muaj kev cuam tshuam hauv cov khoom siv lead ua. Yog li ntawd, txhawm rau txo cov hlau impurities thiab C plua plav, qhov me me ntawm SiC qhov chaw feem ntau yuav tsum tau tswj kom muaj txoj kab uas hla tsawg dua 200 μm, thiab qhov kev loj hlob yuav tsum tsis pub tshaj ∼ 0.4 mm / h kom muaj kev hloov pauv qeeb thiab tsis suav nrog ntab. C plua plav. Hlau impurities thiab C hmoov av ua rau degradation ntawm zus SiC crystals, uas yog lub ntsiab obstacles rau kev loj hlob sai ntawm SiC ntawm txoj kev PVT.

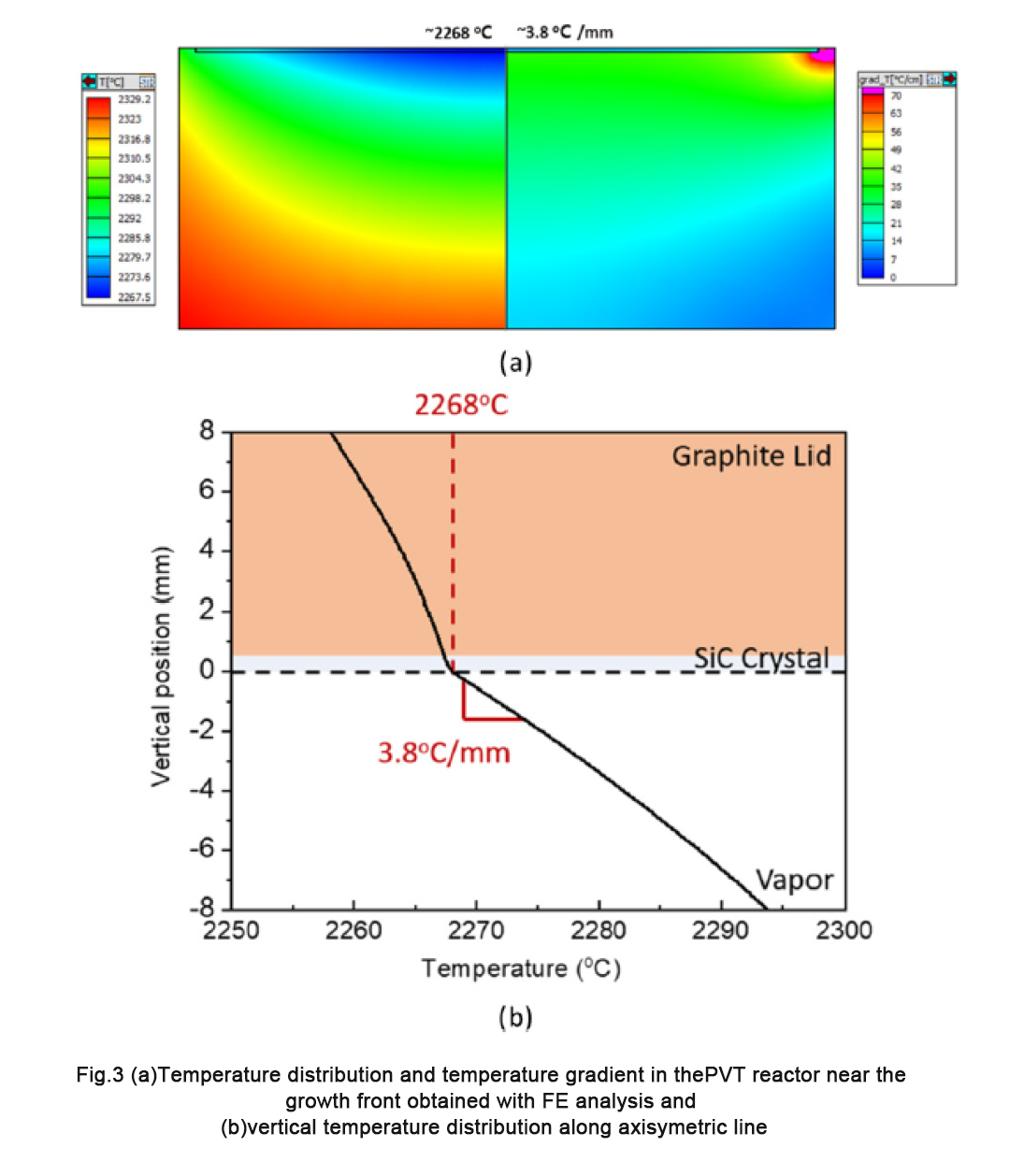

Hauv txoj kev tshawb no, crushed CVD-SiC qhov chaw tsis muaj cov khoom me me tau siv, tshem tawm cov plua plav C hauv qab muaj zog hloov pauv. Yog li, cov qauv thermal cheeb tsam tau tsim los siv multiphysics simulation-raws li PVT txoj kev kom ua tiav SiC kev loj hlob sai, thiab simulated kub faib thiab kub gradient yog qhia nyob rau hauv daim duab 3a.

Daim duab 3: (a) Qhov kub thiab txias gradient nyob ze ntawm kev loj hlob pem hauv ntej ntawm PVT reactor tau los ntawm finite element tsom xam, thiab (b) ntsug kub faib raws kab axisymmetric.

Piv nrog rau qhov chaw thermal thaj chaw rau kev loj hlob SiC crystals ntawm kev loj hlob ntawm 0.3 mus rau 0.8 mm / h nyob rau hauv ib tug me me kub gradient tsawg tshaj li 1 ° C / mm, lub thermal zone chaw nyob rau hauv txoj kev tshawb no muaj ib tug kuj loj kub gradient ntawm ∼ 3.8 ° C / mm ntawm qhov loj hlob ntawm ∼ 2268 ° C. Qhov kub gradient tus nqi hauv txoj kev tshawb no yog piv rau kev loj hlob sai ntawm SiC ntawm tus nqi ntawm 2.4 mm / h siv HTCVD txoj kev, qhov twg qhov kub gradient yog teem rau ∼14 ° C / hli. Los ntawm qhov ntsuas kub ntsug hauv daim duab 3b, peb tau lees paub tias tsis muaj qhov ntsuas kub rov qab uas tuaj yeem tsim cov polycrystals nyob ze ntawm kev loj hlob pem hauv ntej, raws li tau piav qhia hauv cov ntaub ntawv.

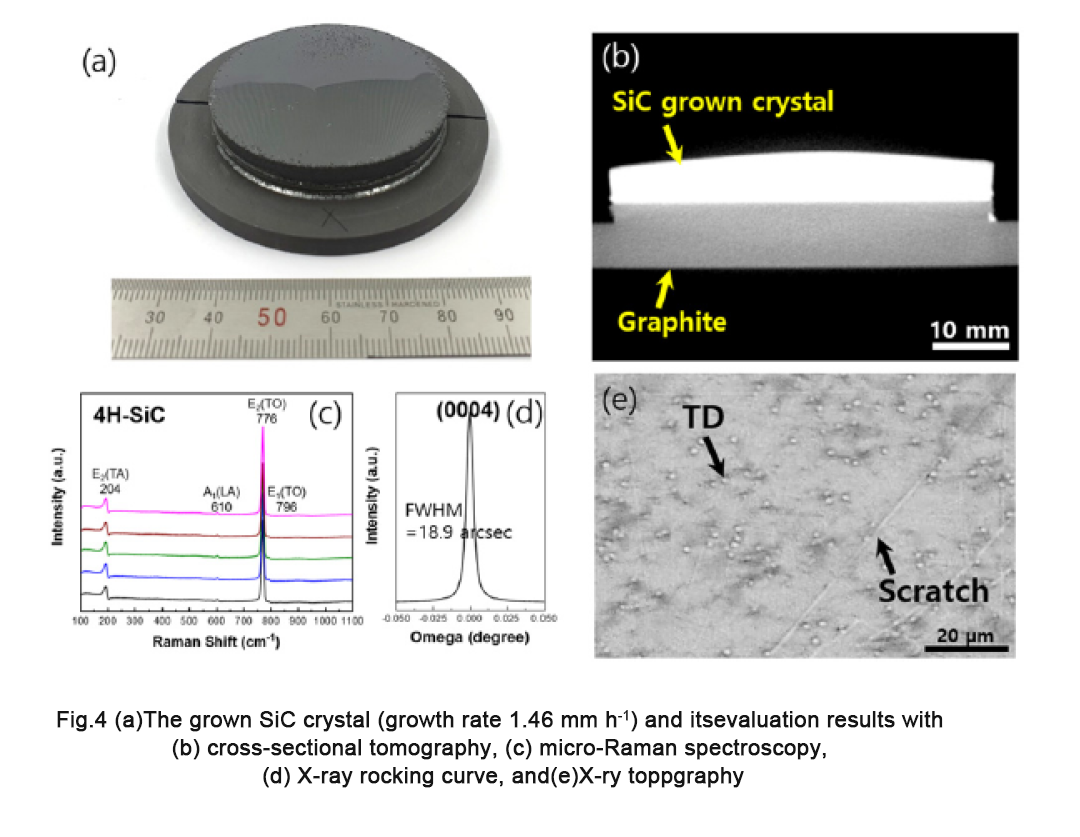

Siv cov txheej txheem PVT, SiC crystals tau loj hlob los ntawm CVD-SiC qhov chaw rau 4 teev, raws li qhia hauv daim duab 2 thiab 3. Ib tus neeg sawv cev SiC siv lead ua los ntawm cov qoob loo SiC yog qhia hauv daim duab 4a. Lub thickness thiab kev loj hlob ntawm SiC siv lead ua nyob rau hauv daim duab 4a yog 5.84 hli thiab 1.46 hli / h, feem. Qhov cuam tshuam ntawm SiC qhov chaw ntawm qhov zoo, polytype, morphology, thiab purity ntawm zus SiC siv lead ua qhia nyob rau hauv daim duab 4a tau soj ntsuam, raws li qhia nyob rau hauv daim duab 4b-e. Daim duab tomography cross-sectional nyob rau hauv daim duab 4b qhia tau hais tias cov siv lead ua kev loj hlob yog convex-puab vim hais tias ntawm lub suboptimal kev loj hlob tej yam kev mob. Txawm li cas los xij, micro-Raman spectroscopy nyob rau hauv daim duab 4c tau txheeb xyuas cov siv lead ua loj hlob raws li ib theem ntawm 4H-SiC yam tsis muaj polytype suav nrog. FWHM tus nqi ntawm (0004) ncov tau los ntawm X-ray rocking nkhaus tsom xam yog 18.9 arcseconds, kuj lees paub qhov zoo siv lead ua zoo.

Daim duab 4: (a) Loj SiC siv lead ua (kev loj hlob ntawm 1.46 mm / h) thiab nws cov txiaj ntsig kev ntsuam xyuas nrog (b) cross-sectional tomography, (c) micro-Raman spectroscopy, (d) X-ray rocking nkhaus, thiab ( e) X-ray topography.

Daim duab 4e qhia cov nqaj dawb X-ray topography txheeb xyuas cov khawb thiab cov xov tsis sib xws hauv polished wafer ntawm cov siv lead ua loj hlob. Lub dislocation ceev ntawm cov noob siv lead ua tau ntsuas yog ∼3000 ea / cm², me ntsis siab dua qhov dislocation ceev ntawm cov noob siv lead ua, uas yog ∼2000 ea / cm². Cov siv lead ua loj hlob tau lees paub tias muaj qhov sib txawv me me, piv rau cov siv lead ua zoo ntawm kev lag luam wafers. Interestingly, kev loj hlob sai ntawm SiC crystals tau tiav siv PVT txoj kev nrog crushed CVD-SiC qhov chaw nyob rau hauv ib tug loj kub gradient. Cov concentrations ntawm B, Al, thiab N nyob rau hauv zus tau tej cov siv lead ua yog 2.18 × 10¹⁶, 7.61 × 10¹⁵, thiab 1.98 × 10¹⁹ atoms / cm³, feem. Qhov concentration ntawm P nyob rau hauv zus tau tej cov siv lead ua yog qis dua qhov kev kuaj pom (<1.0 × 10¹⁴ atoms/cm³). Cov impurity concentrations tau tsawg txaus rau cov nqa khoom, tshwj tsis yog rau N, uas tau txhob txwm doped thaum lub sij hawm CVD txheej txheem.

Txawm hais tias kev loj hlob siv lead ua nyob rau hauv qhov kev tshawb fawb no yog me me txiav txim siab txog cov khoom lag luam, qhov ua tau zoo ntawm SiC kev loj hlob sai nrog cov siv lead ua zoo siv CVD-SiC los ntawm txoj kev PVT muaj qhov cuam tshuam loj. Txij li thaum CVD-SiC cov peev txheej, txawm tias lawv cov khoom zoo heev, yog tus nqi sib tw los ntawm kev rov ua dua cov ntaub ntawv pov tseg, peb cia siab tias lawv yuav siv dav dav raws li SiC cog lus los hloov SiC hmoov. Txhawm rau siv CVD-SiC cov peev txheej rau kev loj hlob sai ntawm SiC, kev ua kom zoo dua qhov kub thiab txias hauv PVT system yog xav tau, ua cov lus nug ntxiv rau kev tshawb fawb yav tom ntej.

Xaus

Nyob rau hauv txoj kev tshawb no, kev ua tau zoo ua qauv qhia ntawm kev loj hlob sai SiC siv lead ua siv crushed CVD-SiC blocks nyob rau hauv high-temperature gradient tej yam kev mob los ntawm txoj kev PVT tau tiav. Interestingly, kev loj hlob sai ntawm SiC crystals tau pom los ntawm kev hloov SiC qhov chaw nrog PVT txoj kev. Txoj kev no yuav tsum tau ua kom muaj txiaj ntsig zoo ntawm SiC ib leeg siv lead ua, thaum kawg txo cov nqi ntawm SiC substrates thiab txhawb kev siv cov khoom siv hluav taws xob ntau.

Post lub sij hawm: Lub Xya hli ntuj-19-2024