Txheej txheem cej luam ntawm Semiconductor txheej txheem

Cov txheej txheem semiconductor feem ntau suav nrog kev siv microfabrication thiab zaj duab xis thev naus laus zis los txuas tag nrho cov chips thiab lwm yam hauv ntau thaj tsam, xws li substrates thiab thav duab. Qhov no pab txhawb kev tshem tawm cov hlau lead terminals thiab encapsulation nrog cov yas insulating nruab nrab los ua ib qho kev sib xyaw ua ke, nthuav tawm raws li cov qauv peb sab, thaum kawg ua tiav cov txheej txheem ntim khoom semiconductor. Lub tswv yim ntawm cov txheej txheem semiconductor kuj muaj feem xyuam rau lub ntsiab lus nqaim ntawm semiconductor nti ntim. Los ntawm kev xav dav dav, nws hais txog kev ntim khoom engineering, uas suav nrog kev sib txuas thiab kho rau lub substrate, teeb tsa cov khoom siv hluav taws xob sib raug zoo, thiab tsim kom muaj kev ua tiav nrog kev ua haujlwm zoo.

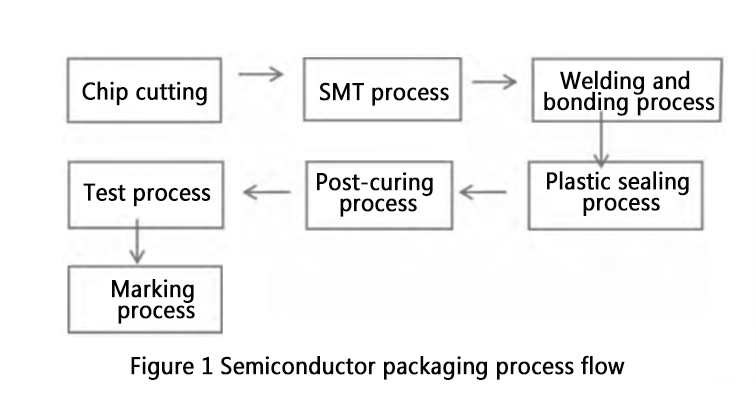

Semiconductor Ntim Txheej Txheem Flow

Cov txheej txheem ntim khoom semiconductor suav nrog ntau yam haujlwm, raws li tau piav qhia hauv daim duab 1. Txhua tus txheej txheem muaj cov kev xav tau tshwj xeeb thiab cov kev ua haujlwm zoo sib xws, yuav tsum tau soj ntsuam cov ncauj lus kom ntxaws thaum lub sijhawm ua haujlwm. Cov ntsiab lus tshwj xeeb yog raws li hauv qab no:

1. Chip Txiav

Nyob rau hauv cov txheej txheem ntim khoom semiconductor, chip txiav yuav tsum txiav cov silicon wafers rau hauv ib tus neeg cov chips thiab tshem tawm cov khoom siv silicon tam sim kom tsis txhob muaj kev cuam tshuam rau kev ua haujlwm tom ntej thiab kev tswj kom zoo.

2. Chip Mounting

Cov txheej txheem nti mounting tsom rau kev zam kev puas tsuaj hauv Circuit Court thaum lub sij hawm wafer sib tsoo los ntawm kev siv cov txheej txheem tiv thaiv zaj duab xis, tsis tu ncua hais txog kev ncaj ncees hauv Circuit Court.

3. Cov txheej txheem xaim hlau

Kev tswj xyuas qhov zoo ntawm cov txheej txheem kev sib txuas ntawm cov hlau txuas nrog kev sib txawv ntawm cov xov hlau kub los txuas cov nti cov ntaub ntawv sib txuas nrog cov ncej pads, kom ntseeg tau tias cov nti tuaj yeem txuas mus rau sab nraud circuits thiab tswj tag nrho cov txheej txheem kev ncaj ncees. Feem ntau, doped kub xov hlau thiab hlau alloyed kub yog siv.

Doped Gold Wires: Hom muaj xws li GS, GW, thiab TS, haum rau high-arc (GS:> 250 μm), nruab nrab-siab arc (GW: 200-300 μm), thiab nruab nrab-tsawg arc (TS: 100-200 μm) sib txuas ua ke.

Alloyed Gold Wires: Hom muaj xws li AG2 thiab AG3, haum rau qis-arc bonding (70-100 μm).

Cov kev xaiv txoj kab uas hla rau cov xov hlau no txawv ntawm 0.013 hli txog 0.070 hli. Xaiv qhov tsim nyog hom thiab txoj kab uas hla raws li kev ua haujlwm thiab cov qauv yog qhov tseem ceeb rau kev tswj kom zoo.

4. Moulding txheej txheem

Lub ntsiab circuitry nyob rau hauv molding ntsiab muaj encapsulation. Kev tswj qhov zoo ntawm cov txheej txheem molding tiv thaiv cov khoom, tshwj xeeb tshaj yog los ntawm sab nraud quab yuam ua rau muaj kev puas tsuaj ntau. Qhov no suav nrog kev tshuaj xyuas zoo ntawm cov khoom siv lub cev.

Peb txoj hauv kev tseem ceeb tam sim no tau siv: ntim cov ceramic, ntim yas, thiab ntim khoom ib txwm siv. Kev tswj hwm qhov kev faib ua feem ntawm txhua hom ntim khoom yog qhov tseem ceeb kom ua tau raws li kev xav tau ntawm cov khoom siv thoob ntiaj teb. Thaum lub sij hawm tus txheej txheem, yuav tsum muaj peev xwm, xws li preheating lub nti thiab txhuas thav duab ua ntej encapsulation nrog epoxy resin, molding, thiab tom qab pwm curing.

5. Cov txheej txheem tom qab kho

Tom qab cov txheej txheem molding, kev kho tom qab yuav tsum tau kho, tsom mus rau tshem tawm cov khoom siv ntau dhau ntawm cov txheej txheem lossis pob. Kev tswj kom zoo yog qhov tseem ceeb kom tsis txhob cuam tshuam tag nrho cov txheej txheem zoo thiab zoo li qub.

6. Cov txheej txheem kuaj

Thaum cov txheej txheem dhau los ua tiav, tag nrho cov txheej txheem zoo yuav tsum tau sim siv cov thev naus laus zis thiab cov cuab yeej siv siab heev. Cov kauj ruam no suav nrog kev sau cov ntaub ntawv ntxaws ntxaws, tsom mus rau seb lub nti ua haujlwm li cas raws li nws qib kev ua haujlwm. Muab tus nqi siab ntawm cov cuab yeej ntsuas, nws yog ib qho tseem ceeb kom tswj tau qhov zoo ntawm cov theem tsim khoom, suav nrog kev tshuaj xyuas qhov muag thiab kev ntsuas hluav taws xob.

Kev Ntsuas Hluav Taws Xob: Qhov no suav nrog kev ntsuas kev sib xyaw ua ke siv cov khoom siv ntsuas tsis siv neeg thiab xyuas kom txhua lub voj voog txuas nrog rau kev ntsuas hluav taws xob.

Kev Ntsuam Xyuas Kev Pom Zoo: Cov kws kho mob siv lub tshuab ntsuas ntsuas kom zoo xyuas cov khoom ntim tiav kom ntseeg tau tias lawv tsis muaj qhov tsis xws luag thiab ua tau raws li cov qauv ntim khoom semiconductor zoo.

7. Cov txheej txheem kos npe

Cov txheej txheem kos npe suav nrog kev xa cov chips kuaj mus rau ib lub tsev muag khoom ib nrab rau kev ua tiav, kev tshuaj xyuas zoo, ntim khoom, thiab xa khoom. Cov txheej txheem no suav nrog peb kauj ruam tseem ceeb:

1) Electroplating: Tom qab tsim cov hlau lead, cov khoom siv tiv thaiv corrosion yog siv los tiv thaiv oxidation thiab corrosion. Electroplating deposition tshuab feem ntau yog siv vim feem ntau cov txhuas yog ua los ntawm tin.

2) Khoov: Cov txheej txheem ua tiav yog tom qab ntawd zoo li tus, nrog rau lub voj voog sib xyaw ua ke muab tso rau hauv cov khoom siv lead ua, tswj cov hlau lead (J lossis L hom) thiab ntim ntim.

3) Laser Printing: Thaum kawg, cov khoom tsim tau luam tawm nrog tus qauv tsim, uas yog lub cim tshwj xeeb rau cov txheej txheem ntim khoom semiconductor, raws li qhia hauv daim duab 3.

Cov kev sib tw thiab cov lus pom zoo

Txoj kev kawm ntawm cov txheej txheem ntim khoom semiconductor pib nrog cov ntsiab lus ntawm cov tshuab semiconductor kom nkag siab txog nws cov ntsiab lus. Tom ntej no, tshuaj xyuas cov txheej txheem ntim cov dej ntws los xyuas kom meej meej kev tswj xyuas thaum lub sijhawm ua haujlwm, siv kev tswj xyuas kom zoo kom tsis txhob muaj teeb meem niaj hnub. Hauv cov ntsiab lus ntawm kev txhim kho niaj hnub no, kev txheeb xyuas cov teeb meem hauv cov txheej txheem ntim khoom semiconductor yog qhov tseem ceeb. Nws raug nquahu kom tsom mus rau kev tswj xyuas qhov zoo, ua tib zoo saib xyuas cov ntsiab lus tseem ceeb txhawm rau txhim kho cov txheej txheem kom zoo.

Kev tshuaj xyuas los ntawm kev tswj xyuas qhov zoo, muaj cov teeb meem tseem ceeb hauv kev siv vim muaj ntau cov txheej txheem nrog cov ntsiab lus tshwj xeeb thiab cov kev xav tau, txhua qhov cuam tshuam rau lwm tus. Kev tswj nruj yog xav tau thaum lub sijhawm ua haujlwm. Los ntawm kev siv tus cwj pwm ua haujlwm zoo thiab siv cov thev naus laus zis siab, cov txheej txheem ntim khoom semiconductor zoo thiab qib kev txawj tuaj yeem txhim kho, ua kom muaj txiaj ntsig zoo ntawm daim ntawv thov thiab ua tiav cov txiaj ntsig zoo tag nrho.(raws li qhia hauv daim duab 3).

Post lub sij hawm: May-22-2024