Ib Txheej txheem cej luam

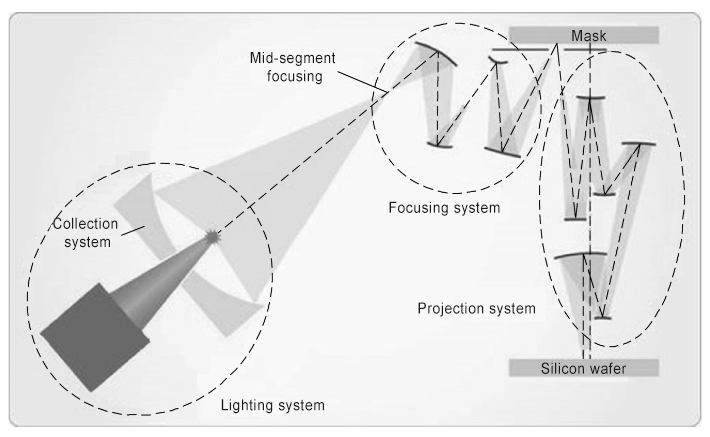

Hauv cov txheej txheem kev tsim hluav taws xob sib xyaw ua ke, photolithography yog cov txheej txheem tseem ceeb uas txiav txim siab qib kev sib koom ua ke ntawm kev sib koom ua ke. Lub luag haujlwm ntawm cov txheej txheem no yog ua ncaj ncees thiab xa cov ntaub ntawv hauv Circuit Court graphic los ntawm lub npog ntsej muag (tseem hu ua lub npog ntsej muag) mus rau cov khoom siv semiconductor substrate.

Lub hauv paus ntsiab lus ntawm cov txheej txheem photolithography yog siv cov tshuaj tiv thaiv photochemical ntawm photoresist coated rau ntawm qhov chaw ntawm lub substrate los sau cov qauv Circuit Court ntawm lub npog ntsej muag, yog li ua tiav lub hom phiaj ntawm kev hloov cov qauv kev sib txuas ntawm cov qauv mus rau lub substrate.

Cov txheej txheem yooj yim ntawm photolithography

Ua ntej, photoresist yog siv rau ntawm qhov chaw substrate siv lub tshuab txheej;

Tom qab ntawd, lub tshuab photolithography yog siv los nthuav tawm cov substrate coated nrog photoresist, thiab photochemical cov tshuaj tiv thaiv mechanism yog siv los sau cov ntaub ntawv npog cov qauv xa los ntawm lub tshuab photolithography, ua kom tiav cov kev sib txuas lus ncaj ncees, hloov pauv thiab rov ua dua ntawm daim npog ntsej muag rau lub substrate;

Thaum kawg, tus tsim tawm yog siv los tsim cov txheej txheem raug tshem tawm kom tshem tawm (lossis khaws cia) cov photoresist uas tau txais cov tshuaj tiv thaiv photochemical tom qab raug.

Ob txheej txheem photolithography

Txhawm rau hloov cov qauv tsim hluav taws xob ntawm lub npog ntsej muag rau silicon wafer, kev hloov pauv yuav tsum ua ntej ua tiav los ntawm cov txheej txheem raug, thiab tom qab ntawd cov qauv silicon yuav tsum tau txais los ntawm cov txheej txheem etching.

Txij li thaum lub teeb pom kev ntawm cov txheej txheem photolithography cheeb tsam siv lub teeb daj daj uas cov ntaub ntawv photosensitive tsis hnov tsw, nws tseem hu ua lub teeb daj.

Photolithography yog thawj zaug siv hauv kev lag luam luam ntawv thiab yog lub tshuab tseem ceeb rau kev tsim PCB thaum ntxov. Txij li thaum xyoo 1950, photolithography tau maj mam dhau los ua cov thev naus laus zis tseem ceeb rau kev hloov pauv hauv IC tsim.

Cov cim tseem ceeb ntawm cov txheej txheem lithography suav nrog kev daws teeb meem, rhiab heev, overlay raug, qhov tsis xws luag, thiab lwm yam.

Cov khoom tseem ceeb tshaj plaws hauv cov txheej txheem photolithography yog photoresist, uas yog cov khoom siv photosensitive. Txij li thaum lub rhiab heev ntawm photoresist nyob ntawm lub wavelength ntawm lub teeb qhov chaw, cov ntaub ntawv sib txawv photoresist yuav tsum tau rau cov txheej txheem photolithography xws li g / i kab, 248nm KrF, thiab 193nm ArF.

Cov txheej txheem tseem ceeb ntawm cov txheej txheem photolithography muaj xws li tsib kauj ruam

:

- Kev npaj zaj duab xis puag;

-Siv photoresist thiab mos ci;

- Kev sib tw, raug thiab tom qab kis tau ci;

-Tsim zaj duab xis nyuaj;

- Kev txhim kho nrhiav pom.

(1)Base zaj duab xis npaj: feem ntau yog ntxuav thiab lub cev qhuav dej. Vim tias tej yam kab mob yuav ua rau tsis muaj zog adhesion ntawm photoresist thiab wafer, kev tu kom huv tuaj yeem txhim kho qhov adhesion ntawm wafer thiab photoresist.

(2)Photoresist txheej: Qhov no yog ua tiav los ntawm kev tig lub silicon wafer. Txawv photoresists xav tau cov txheej txheem txheej txheej sib txawv, suav nrog kev sib hloov ceev, photoresist thickness, thiab kub.

Mos ci: ci tuaj yeem txhim kho qhov adhesion ntawm photoresist thiab silicon wafer, nrog rau kev sib xws ntawm photoresist thickness, uas yog qhov zoo rau kev tswj xyuas meej ntawm qhov ntev geometric ntawm cov txheej txheem etching tom ntej.

(3)Alignment thiab raug: Alignment thiab exposure yog cov kauj ruam tseem ceeb tshaj plaws hauv cov txheej txheem photolithography. Lawv xa mus rau aligning lub npog ntsej muag qauv nrog cov qauv uas twb muaj lawm ntawm lub wafer (los yog cov qauv pem hauv ntej), thiab tom qab ntawd irradiating nws nrog lub teeb tshwj xeeb. Lub teeb lub zog activates lub photosensitive Cheebtsam nyob rau hauv lub photoresist, yog li hloov lub npog qhov ncauj qauv mus rau lub photoresist.

Cov cuab yeej siv rau kev sib tw thiab raug yog lub tshuab photolithography, uas yog cov khoom siv kim tshaj plaws hauv cov txheej txheem kev tsim hluav taws xob tag nrho. Cov txheej txheem ntawm lub tshuab photolithography sawv cev rau theem ntawm kev nce qib ntawm tag nrho cov kab ntau lawm.

Tom qab raug ci: hais txog cov txheej txheem ci luv luv tom qab raug, uas muaj qhov sib txawv ntawm qhov sib sib zog nqus ultraviolet photoresists thiab cov pa i-line photoresists.

Rau kev sib sib zog nqus ultraviolet photoresist, tom qab kis tau ci tshem tawm cov khoom tiv thaiv hauv photoresist, tso cai rau photoresist yaj nyob rau hauv tus tsim tawm, yog li tom qab raug ci yog tsim nyog;

Rau cov pa i-line photoresists, tom qab kis tau ci tuaj yeem txhim kho qhov adhesion ntawm photoresist thiab txo qis sawv ntsug (sawv tsis muaj kev cuam tshuam rau ntawm ntug morphology ntawm photoresist).

(4)Txhim kho zaj duab xis nyuaj: siv tus tsim tawm kom yaj cov soluble ib feem ntawm photoresist (zoo photoresist) tom qab raug, thiab ua kom pom tseeb lub ntsej muag qauv nrog tus qauv photoresist.

Cov tsis tseem ceeb ntawm txoj kev loj hlob muaj xws li kev loj hlob kub thiab lub sij hawm, tus tsim tawm ntau npaum li cas thiab concentration, tu, thiab lwm yam. Los ntawm kev kho cov tsis muaj feem xyuam rau txoj kev loj hlob, qhov sib txawv ntawm dissolution npaum li cas ntawm qhov raug thiab unexposed qhov chaw ntawm lub photoresist yuav nce, yog li ntawd. tau qhov xav tau kev loj hlob zoo.

Hardening tseem hu ua hardening ci, uas yog cov txheej txheem ntawm kev tshem tawm cov kuab tshuaj ntxiv, tus tsim tawm, dej thiab lwm yam khoom tsis tsim nyog nyob rau hauv cov tsim photoresist los ntawm cua sov thiab evaporating lawv, thiaj li los txhim kho cov adhesion ntawm photoresist rau silicon substrate thiab lub etching kuj ntawm photoresist.

Qhov kub ntawm cov txheej txheem hardening txawv nyob ntawm qhov sib txawv photoresists thiab cov txheej txheem hardening. Lub hauv paus yog tias tus qauv photoresist tsis deform thiab photoresist yuav tsum tau ua kom txaus.

(5)Kev tshuaj xyuas kev txhim kho: Qhov no yog los xyuas qhov tsis xws luag hauv cov qauv photoresist tom qab kev loj hlob. Feem ntau, cov cuab yeej paub txog duab yog siv los txiav txim siab cov qauv nti tom qab kev txhim kho thiab muab piv nrog cov qauv khaws cia ua ntej tsis muaj qhov tsis zoo. Yog tias pom muaj qhov sib txawv, nws suav tias yog qhov tsis zoo.

Yog hais tias tus naj npawb ntawm qhov tsis xws luag tshaj ib qho nqi, cov silicon wafer raug txiav txim siab tias qhov kev sim ua tsis tiav thiab yuav raug muab tshem tawm lossis rov ua dua raws li qhov tsim nyog.

Hauv cov txheej txheem kev tsim hluav taws xob sib xyaw ua ke, feem ntau cov txheej txheem tsis tuaj yeem hloov pauv, thiab photolithography yog ib qho ntawm ob peb txheej txheem uas tuaj yeem rov ua haujlwm dua.

Peb photomasks thiab cov khoom siv photoresist

3.1 Photomask

Lub photomask, tseem hu ua photolithography daim npog qhov ncauj, yog ib tug tswv siv nyob rau hauv cov txheej txheem photolithography ntawm integrated circuit wafer manufacturing.

Cov txheej txheem tsim photomask yog los hloov cov ntaub ntawv tseem ceeb uas xav tau rau kev tsim khoom wafer tsim los ntawm kev sib koom ua ke hauv Circuit Court engineers rau hauv cov ntaub ntawv uas tuaj yeem lees paub los ntawm laser qauv generators lossis cov khoom siv hluav taws xob raug hluav taws xob los ntawm cov ntaub ntawv npog ntsej muag, kom nws tuaj yeem raug pom los ntawm cov khoom siv saum toj no ntawm cov khoom siv photomask substrate coated nrog cov khoom siv photosensitive; tom qab ntawd nws tau ua tiav los ntawm ntau cov txheej txheem xws li kev txhim kho thiab etching los kho cov qauv ntawm cov khoom siv substrate; Thaum kawg, nws raug tshuaj xyuas, kho, ntxuav, thiab zaj duab xis-laminated los tsim cov khoom siv npog ntsej muag thiab xa mus rau cov chaw tsim khoom siv hluav taws xob sib xyaw.

3.2 Photoresist

Photoresist, tseem hu ua photoresist, yog cov khoom siv photosensitive. Lub photosensitive Cheebtsam nyob rau hauv nws yuav undergone tshuaj hloov nyob rau hauv lub irradiation ntawm lub teeb, yog li ua rau kev hloov nyob rau hauv lub dissolution tus nqi. Nws lub luag haujlwm tseem ceeb yog hloov cov qauv ntawm lub npog ntsej muag mus rau lub substrate xws li wafer.

Ua hauj lwm hauv paus ntsiab lus ntawm photoresist: Ua ntej, lub photoresist yog coated ntawm lub substrate thiab pre-ci kom tshem tawm cov hnyav;

Thib ob, lub npog ntsej muag raug rau lub teeb, ua rau cov khoom siv photosensitive nyob rau hauv qhov chaw raug rau cov tshuaj tiv thaiv;

Tom qab ntawd, lub ncuav ci tom qab kis tau;

Thaum kawg, cov photoresist yog ib nrab yaj los ntawm kev txhim kho (rau qhov zoo photoresist, thaj chaw raug yaj; rau qhov tsis zoo photoresist, qhov chaw tsis pom kev yog yaj), yog li paub txog kev hloov pauv ntawm cov qauv sib xyaw ua ke los ntawm daim npog ntsej muag mus rau substrate.

Lub Cheebtsam ntawm photoresist mas muaj xws li zaj duab xis-forming resin, photosensitive tivthaiv, kab additives thiab hnyav.

Ntawm lawv, zaj duab xis-forming resin yog siv los muab cov khoom siv kho tshuab thiab etching tsis kam; cov photosensitive tivthaiv undergoes tshuaj hloov nyob rau hauv lub teeb, ua rau kev hloov nyob rau hauv lub dissolution tus nqi;

Cov khoom siv ntxiv muaj xws li dyes, viscosity enhancers, thiab lwm yam, uas yog siv los txhim kho kev ua haujlwm ntawm photoresist; cov kuab tshuaj yog siv los yaj cov khoom thiab sib tov sib npaug.

Lub photoresists tam sim no nyob rau hauv dav siv tau muab faib ua ib txwm photoresists thiab tshuaj amplified photoresists raws li photochemical tshuaj tiv thaiv mechanism, thiab kuj yuav muab faib ua ultraviolet, tob ultraviolet, ultraviolet ultraviolet, electron beam, ion beam thiab X-ray photoresists raws li tus photosensitivity wavelength ntawm cov duab.

Plaub cov khoom siv photolithography

Photolithography thev naus laus zis tau dhau los ntawm cov txheej txheem kev loj hlob ntawm kev sib cuag / sib thooj lithography, kho qhov muag lithography, kauj ruam-thiab-repeat lithography, scanning lithography, immersion lithography, thiab EUV lithography.

4.1 Sib cuag / Sib Nqus Lithography Tshuab

Hu rau lithography tshuab tau tshwm sim hauv xyoo 1960 thiab tau siv dav hauv xyoo 1970. Nws yog lub ntsiab lithography txoj kev nyob rau hauv lub era ntawm me me integrated circuits thiab yog tsuas yog siv los tsim integrated circuits nrog feature ntau thiab tsawg tshaj li 5μm.

Hauv kev sib cuag / qhov sib thooj lithography tshuab, wafer feem ntau yog muab tso rau ntawm tus kheej tswj txoj haujlwm kab rov tav thiab tig lub rooj ua haujlwm. Tus neeg teb xov tooj siv lub tshuab ntsuas hluav taws xob sib cais los saib xyuas txoj hauj lwm ntawm lub npog ntsej muag thiab wafer, thiab manually tswj txoj hauj lwm ntawm lub rooj ua hauj lwm kom haum lub ntsej muag thiab wafer. Tom qab lub wafer thiab daim npog ntsej muag raug sib dhos, ob qho tib si yuav raug nias ua ke kom lub npog ntsej muag yog nyob rau hauv kev sib cuag ncaj qha nrog photoresist ntawm qhov chaw ntawm lub wafer.

Tom qab tshem tawm lub hom phiaj ntawm lub tshuab tsom iav, cov xovxwm wafer thiab daim npog ntsej muag raug txav mus rau lub rooj sib kis kom raug. Lub teeb emissions los ntawm lub teeb mercury yog collimated thiab parallel mus rau lub ntsej muag los ntawm ib lub lens. Txij li thaum lub npog ntsej muag yog nyob rau hauv kev sib cuag ncaj qha nrog cov txheej txheem photoresist ntawm lub wafer, lub npog ntsej muag yog pauv mus rau txheej txheej photoresist ntawm qhov sib piv ntawm 1: 1 tom qab raug.

Hu rau cov khoom siv lithography yog qhov yooj yim tshaj plaws thiab pheej yig tshaj plaws optical lithography cov cuab yeej, thiab tuaj yeem ua tiav qhov cuam tshuam ntawm sub-micron feature loj cov duab, yog li nws tseem siv rau hauv kev tsim khoom me me thiab kev tshawb fawb hauv chav kuaj. Hauv kev tsim hluav taws xob loj sib xyaw ua ke, qhov sib thooj lithography thev naus laus zis tau qhia kom tsis txhob muaj qhov nce ntawm lithography cov nqi tshwm sim los ntawm kev sib cuag ncaj qha ntawm lub npog ntsej muag thiab lub wafer.

Kev sib thooj lithography tau dav siv nyob rau xyoo 1970s thaum lub sijhawm me me kev sib xyaw circuits thiab lub sijhawm thaum ntxov ntawm nruab nrab-teev kev sib xyaw circuits. Tsis zoo li kev sib cuag lithography, lub npog ntsej muag hauv qhov sib thooj lithography tsis yog nyob rau hauv kev sib cuag ncaj qha nrog lub photoresist ntawm lub wafer, tab sis qhov sib txawv uas muaj nitrogen yog sab laug. Lub npog ntsej muag ntab ntawm cov nitrogen, thiab qhov loj ntawm qhov sib txawv ntawm lub npog ntsej muag thiab wafer yog txiav txim siab los ntawm nitrogen siab.

Txij li thaum tsis muaj kev sib cuag ncaj qha ntawm wafer thiab lub npog ntsej muag nyob rau hauv qhov sib thooj lithography, qhov tsis xws luag qhia thaum lub sij hawm lithography txheej txheem raug txo, yog li txo qhov poob ntawm lub npog ntsej muag thiab txhim kho wafer tawm los. Hauv qhov sib thooj lithography, qhov sib txawv ntawm wafer thiab lub npog ntsej muag tso lub wafer nyob rau hauv cheeb tsam Fresnel diffraction. Lub xub ntiag ntawm diffraction txwv qhov kev txhim kho ntxiv ntawm kev daws teeb meem ntawm cov khoom sib thooj lithography, yog li cov cuab yeej no tsuas yog tsim nyog rau kev tsim cov kev sib xyaw ua ke nrog qhov ntau thiab tsawg tshaj 3μm.

4.2 Stepper thiab Repeater

Stepper yog ib qho khoom siv tseem ceeb tshaj plaws hauv keeb kwm ntawm wafer lithography, uas tau txhawb nqa cov txheej txheem sub-micron lithography rau hauv ntau lawm. Tus stepper siv qhov chaw raug zoo li qub ntawm 22mm × 22mm thiab lub lens optical projection nrog qhov txo qis ntawm 5: 1 lossis 4: 1 kom hloov cov qauv ntawm lub npog ntsej muag mus rau wafer.

Cov kauj ruam-thiab-repeat lithography tshuab feem ntau yog tsim los ntawm kev cuam tshuam subsystem, lub workpiece theem subsystem, lub npog ncauj theem subsystem, ib tug tsom/leveling subsystem, ib tug alignment subsystem, lub ntsiab ncej subsystem, ib tug wafer hloov subsystem, lub npog qhov ncauj hloov subsystem. , ib qho hluav taws xob subsystem, thiab software subsystem.

Cov txheej txheem ua hauj lwm ntawm ib kauj ruam-thiab-repeat lithography tshuab yog raws li nram no:

Ua ntej, lub wafer coated nrog photoresist yog pauv mus rau lub rooj workpiece los ntawm kev siv lub wafer hloov subsystem, thiab lub npog qhov ncauj yuav tsum tau pauv mus rau lub npog qhov ncauj lub rooj los ntawm kev siv lub npog qhov ncauj hloov subsystem;

Tom qab ntawd, lub kaw lus siv qhov kev tsom xam / qib theem subsystem los ua qhov ntsuas qhov siab ntawm ntau qhov ntawm lub wafer ntawm lub workpiece theem kom tau txais cov ntaub ntawv xws li qhov siab thiab qaij lub kaum sab xis ntawm qhov chaw ntawm lub wafer kom raug, kom qhov chaw raug. lub wafer yeej ib txwm tswj tau nyob rau hauv lub focal tob ntawm lub projection lub hom phiaj thaum lub sij hawm raug tus txheej txheem;Tom qab ntawd, lub kaw lus siv cov txheej txheem kev sib txuas ua ke los ua kom lub ntsej muag thiab wafer kom lub sij hawm raug cov txheej txheem qhov tseeb ntawm daim npog qhov ncauj qhov ntswg thiab wafer qauv hloov mus rau ib txwm nyob rau hauv cov kev cai overlay.

Thaum kawg, cov kauj ruam-thiab-tshwj xeeb ntawm tag nrho wafer nto yog ua tiav raws li txoj hauv kev kom paub txog cov qauv hloov pauv.

Tom ntej no stepper thiab scanner lithography tshuab yog ua raws li cov txheej txheem kev ua haujlwm saum toj no, txhim kho cov kauj ruam → raug xa mus rau scanning → raug, thiab tsom / qib → kev sib tw → raug rau ntawm tus qauv dual-theem rau kev ntsuas (tseem ceeb / qib → kev sib tw) thiab luam theej duab raug nyob rau hauv parallel.

Piv nrog rau cov kauj ruam-thiab-scan lithography tshuab, cov kauj ruam-thiab-repeat lithography tshuab tsis tas yuav ua kom tiav synchronous thim rov qab scanning ntawm lub npog ntsej muag thiab wafer, thiab tsis tas yuav tsum muaj lub ntsej muag lub ntsej muag scanning thiab synchronous scanning system. Yog li ntawd, cov qauv yog qhov yooj yim, tus nqi qis, thiab kev ua haujlwm yog txhim khu kev qha.

Tom qab IC thev naus laus zis nkag mus rau 0.25μm, daim ntawv thov ntawm cov kauj ruam-thiab-repeat lithography pib poob vim qhov zoo ntawm cov kauj ruam-thiab-scan lithography hauv scanning raug thaj tsam loj thiab raug sib xws. Tam sim no, qhov tseeb cov kauj ruam-thiab-repeat lithography muab los ntawm Nikon muaj qhov chaw zoo li qub ntawm kev pom qhov loj li ntawm cov kauj ruam-thiab-scan lithography, thiab tuaj yeem ua tiav ntau dua 200 wafers ib teev, nrog rau kev ua haujlwm siab heev. Hom lithography tshuab tam sim no tsuas yog siv rau kev tsim cov txheej txheem IC tsis tseem ceeb.

4.3 Stepper Scanner

Daim ntawv thov ntawm kauj ruam-thiab-scan lithography pib hauv 1990s. Los ntawm kev teeb tsa lub teeb pom kev sib txawv, cov txheej txheem thev naus laus zis tuaj yeem txhawb nqa cov txheej txheem sib txawv, los ntawm 365nm, 248nm, 193nm immersion rau EUV lithography. Tsis zoo li cov kauj ruam-thiab-repeat lithography, ib leeg-tsav kis ntawm kauj ruam-thiab-scan lithography txais yuav dynamic scanning, uas yog, daim npog ntsej muag ua tiav lub scanning txav synchronously txheeb ze rau wafer; Tom qab qhov kev nthuav tawm tam sim no tiav lawm, lub wafer yog nqa los ntawm lub workpiece theem thiab nqis mus rau tom ntej scanning teb txoj hauj lwm, thiab rov kis tau mus ntxiv; rov ua cov kauj ruam-thiab-scan raug ntau zaus kom txog thaum tag nrho cov teb ntawm tag nrho cov wafer raug.

Los ntawm kev teeb tsa ntau hom teeb pom kev zoo (xws li i-line, KrF, ArF), lub kauj ruam-scanner tuaj yeem txhawb nqa yuav luag txhua qhov thev naus laus zis ntawm cov txheej txheem semiconductor pem hauv ntej kawg. Cov txheej txheem silicon-raws li CMOS tau txais cov txheej txheem-scanners hauv ntau qhov txij li 0.18μm ntawm; cov huab ultraviolet (EUV) lithography tshuab tam sim no siv nyob rau hauv cov txheej txheem ntawm qis dua 7nm kuj siv stepper-scanning. Tom qab kev hloov kho ib nrab, lub kauj ruam-scanner kuj tuaj yeem txhawb kev tshawb fawb thiab kev tsim kho thiab tsim ntau cov txheej txheem uas tsis yog-silicon xws li MEMS, cov khoom siv hluav taws xob, thiab RF.

Lub tuam txhab tseem ceeb ntawm kauj ruam-thiab-scan projection lithography tshuab suav nrog ASML (Netherlands), Nikon (Nyiv), Canon (Nyiv) thiab SMEE (Tuam Tshoj). ASML launched TWINSCAN series ntawm kauj ruam-thiab-scan lithography tshuab nyob rau hauv 2001. Nws txais ib tug dual-theem system architecture, uas yuav ua tau zoo txhim kho cov zis tus nqi ntawm cov khoom thiab tau dhau los ua lub feem ntau lug siv high-end lithography tshuab.

4.4 Immersion Lithography

Nws tuaj yeem pom los ntawm Rayleigh cov mis nyuj uas, thaum qhov kev cuam tshuam wavelength tseem tsis hloov pauv, txoj hauv kev zoo los txhim kho cov duab daws teeb meem ntxiv yog txhawm rau nce tus lej aperture ntawm cov duab duab. Rau kev daws teeb meem hauv qab 45nm thiab siab dua, ArF qhuav raug txoj kev tsis tuaj yeem ua tau raws li qhov yuav tsum tau ua (vim tias nws txhawb nqa qhov kev daws teeb meem siab tshaj plaws ntawm 65nm), yog li nws yog qhov yuav tsum tau ua kom paub txog txoj kev immersion lithography. Hauv kev siv tshuab lithography ib txwm muaj, qhov nruab nrab ntawm lub lens thiab photoresist yog huab cua, thaum immersion lithography technology hloov cov huab cua nruab nrab nrog kua (feem ntau yog ultrapure dej nrog ib tug refractive index ntawm 1.44).

Qhov tseeb, immersion lithography tshuab siv lub shortening ntawm lub wavelength ntawm lub teeb qhov chaw tom qab lub teeb dhau los ntawm cov kua nruab nrab los txhim kho qhov kev daws teeb meem, thiab qhov shortening piv yog lub refractive index ntawm cov kua nruab nrab. Txawm hais tias lub tshuab lithography immersion yog ib hom step-and-scan lithography tshuab, thiab nws cov cuab yeej siv kev daws teeb meem tsis tau hloov, nws yog kev hloov kho thiab nthuav dav ntawm ArF kauj ruam-thiab-scan lithography tshuab vim kev qhia txog cov thev naus laus zis tseem ceeb ntsig txog. rau immersion.

Qhov kom zoo dua ntawm immersion lithography yog tias, vim qhov nce ntawm cov lej aperture ntawm lub kaw lus, cov duab daws teeb meem muaj peev xwm ntawm stepper-scanner lithography tshuab tau txhim kho, uas tuaj yeem ua tau raws li cov txheej txheem ntawm kev daws teeb meem hauv qab 45nm.

Txij li thaum lub tshuab immersion lithography tseem siv ArF lub teeb ci, qhov txuas ntxiv ntawm cov txheej txheem yog lav, txuag R & D nqi ntawm lub teeb ci, khoom siv thiab txheej txheem. Rau lub hauv paus no, ua ke nrog ntau yam duab thiab kev siv tshuab lithography, immersion lithography tshuab tuaj yeem siv ntawm cov txheej txheem ntawm 22nm thiab hauv qab no. Ua ntej EUV lithography tshuab tau raug muab tso rau hauv ntau lawm, lub tshuab lithography immersion tau siv dav thiab tuaj yeem ua tau raws li cov txheej txheem ntawm 7nm node. Txawm li cas los xij, vim qhov kev taw qhia ntawm cov kua immersion, qhov teeb meem engineering ntawm cov cuab yeej nws tus kheej tau nce ntau.

Nws cov thev naus laus zis tseem ceeb suav nrog immersion kua mov thiab rov qab siv tshuab, immersion ua kua field tu tshuab, immersion lithography kua paug thiab tsis xws luag tswj technology, kev loj hlob thiab txij nkawm ntawm ultra-loj lej aperture immersion projection lo ntsiab muag, thiab imaging zoo nrhiav tshuab nyob rau hauv immersion tej yam kev mob.

Tam sim no, kev lag luam ArFi kauj ruam-thiab-scan lithography tshuab yog muab los ntawm ob lub tuam txhab, xws li ASML ntawm Netherlands thiab Nikon ntawm Nyiv. Ntawm lawv, tus nqi ntawm ib qho ASML NXT1980 Di yog kwv yees li 80 lab euros.

4.5 Ultraviolet Lithography tshuab

Txhawm rau txhim kho qhov kev daws teeb meem ntawm photolithography, qhov raug wavelength raug txuas ntxiv luv dua tom qab siv lub teeb pom kev zoo, thiab cov teeb pom kev zoo ultraviolet nrog lub wavelength ntawm 10 mus rau 14 nm tau qhia raws li lub teeb pom kev. Lub wavelength ntawm lub teeb ultraviolet tsis tshua muaj luv luv, thiab lub teeb pom kev zoo uas tuaj yeem siv tau feem ntau yog tsim los ntawm ntau cov yeeb yaj kiab reflectors xws li Mo / Si lossis Mo / Be.

Ntawm lawv, qhov theoretical siab tshaj qhov xav tau ntawm Mo / Si multilayer zaj duab xis nyob rau hauv lub wavelength ntau ntawm 13.0 txog 13.5nm yog li 70%, thiab qhov theoretical siab tshaj plaws ntawm Mo / Be multilayer zaj duab xis ntawm luv luv wavelength ntawm 11.1nm yog li 80%. Txawm hais tias qhov kev xav ntawm Mo / Be multilayer film reflectors yog siab dua, Be yog cov tshuaj lom heev, yog li kev tshawb fawb ntawm cov ntaub ntawv no raug tso tseg thaum tsim EUV lithography technology.Tam sim no EUV lithography tshuab siv Mo / Si multilayer zaj duab xis, thiab nws qhov kev cuam tshuam wavelength kuj tau txiav txim siab yog 13.5nm.

Lub ntsiab hluav taws xob ultraviolet lub teeb pom kev zoo siv cov tshuab laser tsim cov ntshav (LPP), uas siv cov lasers siab siv los ua kom kub-melt Sn plasma kom tawm lub teeb. Rau lub sijhawm ntev, lub zog thiab qhov muaj nyob ntawm lub teeb ci tau ua rau muaj kev txwv tsis pub ua haujlwm ntawm EUV lithography tshuab. Los ntawm tus tswv oscillator fais fab amplifier, kev kwv yees ntshav plasma (PP) thev naus laus zis thiab hauv-situ sau daim iav tu tshuab, lub zog thiab kev ruaj ntseg ntawm EUV lub teeb pom kev zoo tau txhim kho zoo heev.

Lub tshuab EUV lithography yog tsim los ntawm subsystems xws li lub teeb qhov chaw, teeb pom kev zoo, lub hom phiaj lens, workpiece theem, daim npog qhov ncauj, wafer alignment, focusing/leveling, mask transmission, wafer transmission, and vacuum frame. Tom qab dhau los ntawm lub teeb pom kev zoo tsim los ntawm ntau txheej txheej coated reflectors, lub teeb ultraviolet huab cua yog irradiated ntawm daim npog ntsej muag. Lub teeb pom kev los ntawm lub npog ntsej muag nkag mus rau qhov kho qhov muag tag nrho qhov kev xav pom qhov system tsim los ntawm cov khoom siv hluav taws xob, thiab thaum kawg cov duab pom ntawm lub npog ntsej muag yog npaj rau saum npoo ntawm wafer hauv ib puag ncig lub tshuab nqus tsev.

Kev nthuav dav ntawm kev pom thiab kev pom kev pom ntawm EUV lithography tshuab yog ob qho tib si arc-zoo li tus, thiab ib kauj ruam-los-kauj ruam scanning txoj kev yog siv los ua kom tiav tag nrho wafer raug los txhim kho cov zis tawm. ASML's siab tshaj plaws NXE series EUV lithography tshuab siv lub teeb pom kev zoo nrog lub wavelength ntawm 13.5nm, lub ntsej muag lub ntsej muag (6 ° oblique tshwm sim), 4x txo qhov cuam tshuam qhov projection lub hom phiaj nrog 6- daim iav qauv (NA = 0.33), a scanning teb pom ntawm 26mm × 33mm, thiab lub tshuab nqus tsev raug.

Piv nrog rau cov tshuab lithography immersion, ib qho kev daws teeb meem ntawm EUV lithography tshuab siv cov khoom siv hluav taws xob ultraviolet tau zoo heev, uas tuaj yeem zam cov txheej txheem nyuaj uas yuav tsum tau muaj rau ntau lub photolithography los tsim cov duab siab. Tam sim no, ib qho kev daws teeb meem ntawm NXE 3400B lithography tshuab nrog tus lej aperture ntawm 0.33 txog 13nm, thiab cov zis tawm mus txog 125 daim / h.

Txhawm rau ua kom tau raws li qhov xav tau ntawm kev txuas ntxiv ntawm Moore Txoj Cai, yav tom ntej, EUV lithography tshuab nrog tus lej aperture ntawm 0.5 yuav siv lub hom phiaj phiaj xwm phiaj xwm nrog lub teeb pom kev hauv nruab nrab, siv qhov kev nthuav dav asymmetric ntawm 0.25 zaug / 0.125 zaug, thiab scanning exposure teb ntawm saib yuav raug txo los ntawm 26m × 33mm mus rau 26mm × 16.5mm, thiab ib leeg. Kev daws teeb meem raug tuaj yeem ncav cuag qis dua 8nm.

———————————————————————————————————————————————————————— ————————————————

Semicera tuaj yeem muab taugraphite qhov chaw, soft/rigid xav, silicon carbide qhov chaw, CVD silicon carbide qhov chaw, thiabSiC/TaC coated qhov chawnrog tag nrho cov txheej txheem semiconductor hauv 30 hnub.

Yog tias koj txaus siab rau cov khoom lag luam semiconductor saum toj no,thov tsis txhob yig tiv tauj peb thawj zaug.

Tel: +86-13373889683

WhatsApp: +86-15957878134

Email: sales01@semi-cera.com

Post lub sij hawm: Aug-31-2024