Ib Taw Qhia

Etching nyob rau hauv lub integrated circuit manufacturing txheej txheem yog muab faib ua:

- ntub dej etching;

- Qhuav etching.

Thaum ntxov, ntub etching tau dav siv, tab sis vim nws cov kev txwv nyob rau hauv kab dav tswj thiab etching directionality, feem ntau cov txheej txheem tom qab 3μm siv qhuav etching. Kev ntub dej etching tsuas yog siv los tshem tawm qee yam khoom tshwj xeeb txheej thiab huv si seem.

Qhuav etching yog hais txog cov txheej txheem ntawm kev siv cov tshuaj gaseous etchants los teb cov ntaub ntawv ntawm lub wafer kom tshem tawm ib feem ntawm cov khoom uas yuav tsum tau muab tshem tawm thiab tsim cov tshuaj tiv thaiv tsis haum, uas tau muab rho tawm los ntawm cov tshuaj tiv thaiv chamber. Etchant feem ntau yog tsim ncaj qha lossis tsis ncaj los ntawm cov ntshav ntawm cov roj etching, yog li qhuav etching tseem hu ua plasma etching.

1.1 Plasma

Plasma yog ib qho roj nyob rau hauv lub xeev tsis muaj zog ionized tsim los ntawm glow tawm ntawm etching gas nyob rau hauv qhov kev txiav txim ntawm sab nraud electromagnetic teb (xws li generated los ntawm ib tug xov tooj cua zaus fais fab mov). Nws muaj xws li electrons, ions thiab nruab nrab active hais. Ntawm lawv, cov khoom nquag tuaj yeem cuam tshuam ncaj qha rau cov khoom siv etched kom ua tiav etching, tab sis cov tshuaj dawb huv no feem ntau tsuas yog tshwm sim hauv cov ntaub ntawv tsawg heev thiab tsis yog kev taw qhia; Thaum cov ions muaj qee lub zog, lawv tuaj yeem raug etched los ntawm lub cev ncaj qha sputtering, tab sis qhov etching tus nqi ntawm cov tshuaj tiv thaiv lub cev ntshiab no tsawg heev thiab cov kev xaiv tsis zoo.

Feem ntau plasma etching yog ua tiav nrog kev koom tes ntawm cov khoom nquag thiab ions tib lub sijhawm. Hauv cov txheej txheem no, ion bombardment muaj ob txoj haujlwm. Ib qho yog txhawm rau rhuav tshem cov atomic bonds ntawm qhov chaw ntawm cov khoom siv etched, yog li nce tus nqi ntawm cov khoom nruab nrab ntawm nws; Lwm qhov yog txhawm rau tshem tawm cov tshuaj tiv thaiv cov khoom tso rau ntawm cov tshuaj tiv thaiv kev sib txuas los pab txhawb lub etchant kom tag nrho hu rau saum npoo ntawm cov khoom siv etched, kom cov etching txuas ntxiv mus.

Cov khoom siv tshuaj tiv thaiv tso rau ntawm phab ntsa ntawm cov qauv etched tsis tuaj yeem raug tshem tawm zoo los ntawm kev taw qhia ion bombardment, yog li thaiv qhov etching ntawm phab ntsa thiab tsim anisotropic etching.

Qhov thib ob etching txheej txheem

2.1 Kev ntub dej thiab ntxuav

Kev ntub dej ntub dej yog ib qho ntawm cov thev naus laus zis tshaj plaws uas siv hauv kev tsim hluav taws xob sib txuas. Txawm hais tias feem ntau cov txheej txheem ntub dej tau raug hloov los ntawm anisotropic qhuav etching vim nws cov isotropic etching, nws tseem ua lub luag haujlwm tseem ceeb hauv kev ntxuav cov txheej tsis tseem ceeb ntawm qhov loj dua. Tshwj xeeb tshaj yog nyob rau hauv etching ntawm oxide tshem tawm residues thiab epidermal stripping, nws yog zoo dua thiab yig dua qhuav etching.

Cov khoom ntawm ntub etching feem ntau suav nrog silicon oxide, silicon nitride, ib leeg siv lead ua silicon thiab polycrystalline silicon. Kev ntub dej ntawm silicon oxide feem ntau siv hydrofluoric acid (HF) ua cov khoom siv tshuaj lom neeg tseem ceeb. Txhawm rau txhim kho kev xaiv, dilute hydrofluoric acid buffered los ntawm ammonium fluoride yog siv hauv cov txheej txheem. Txhawm rau kom muaj kev ruaj ntseg ntawm tus nqi pH, ib qho me me ntawm cov kua qaub muaj zog lossis lwm yam khoom tuaj yeem ntxiv. Doped silicon oxide yog yooj yim corroded dua li ntshiab silicon oxide. Cov tshuaj ntub dej ntub dej feem ntau yog siv los tshem tawm cov photoresist thiab lub ntsej muag tawv (silicon nitride). Kub phosphoric acid (H3PO4) yog cov kua tshuaj tseem ceeb siv rau cov tshuaj ntub dej kom tshem tawm silicon nitride, thiab muaj kev xaiv zoo rau silicon oxide.

Kev ntxuav ntub dej yog zoo ib yam li ntub dej etching, thiab feem ntau tshem tawm cov pa phem ntawm qhov chaw ntawm silicon wafers los ntawm cov tshuaj tiv thaiv, nrog rau cov khoom, cov khoom organic, hlau thiab oxides. Txoj kev ntub dej tseem ceeb yog txoj kev ntub dej. Txawm hais tias kev tu kom qhuav tuaj yeem hloov tau ntau txoj kev tu ntub dej, tsis muaj ib txoj hauv kev uas tuaj yeem hloov cov ntaub ntub ntub.

Feem ntau siv cov tshuaj ntxhua khaub ncaws ntub dej xws li sulfuric acid, hydrochloric acid, hydrofluoric acid, phosphoric acid, hydrogen peroxide, ammonium hydroxide, ammonium fluoride, thiab lwm yam. Hauv kev siv tswv yim, ib lossis ntau cov tshuaj yog tov nrog dej deionized hauv ib qho kev faib ua feem raws li xav tau. tsim cov tshuaj ntxuav, xws li SC1, SC2, DHF, BHF, thiab lwm yam.

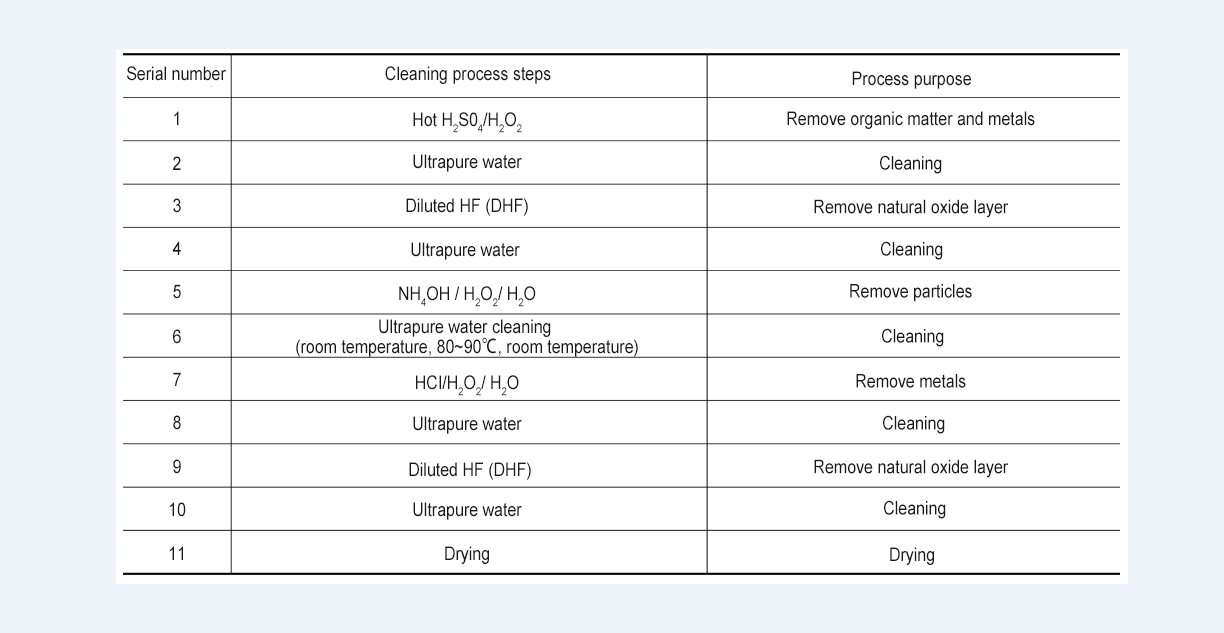

Kev ntxuav feem ntau yog siv rau hauv cov txheej txheem ua ntej oxide zaj duab xis deposition, vim hais tias kev npaj ntawm oxide zaj duab xis yuav tsum tau nqa tawm ntawm ib tug kiag li huv silicon wafer nto. Cov txheej txheem ntawm silicon wafer tu yog raws li nram no:

2.2 Qhuav Etching thiab tu

2.2.1 Qhuav Etching

Qhuav etching hauv kev lag luam feem ntau yog hais txog plasma etching, uas siv cov plasma nrog kev ua kom zoo dua rau cov khoom tshwj xeeb. Cov cuab yeej siv hauv cov txheej txheem tsim khoom loj siv cov plasma kub uas tsis muaj qhov sib npaug.

Plasma etching feem ntau yog siv ob hom kev tso tawm: capacitive coupled paug thiab inductive txuas txuas

Nyob rau hauv lub capacitively coupling discharge hom: plasma yog generated thiab tswj nyob rau hauv ob parallel phaj capacitors los ntawm ib tug sab nraud xov tooj cua zaus (RF) fais fab mov. Cov roj siab feem ntau yog ob peb millitorr mus rau kaum millitorr, thiab tus nqi ionization tsawg dua 10-5. Nyob rau hauv hom inductively co tso tawm: feem ntau ntawm ib tug qis roj siab (tsawg millitorr), lub plasma yog generated thiab tswj los ntawm inductively txuas input zog. Tus nqi ionization feem ntau yog ntau dua 10-5, yog li nws tseem hu ua high-density plasma. High-density plasma qhov chaw kuj tuaj yeem tau txais los ntawm electron cyclotron resonance thiab cyclotron yoj tawm. High-density plasma tuaj yeem txhim kho tus nqi etching thiab kev xaiv ntawm cov txheej txheem etching thaum txo qis kev puas tsuaj los ntawm nws tus kheej tswj cov ion ntws thiab ion foob pob hluav taws xob los ntawm sab nraud RF lossis microwave fais fab mov thiab RF bias fais fab mov ntawm lub substrate.

Cov txheej txheem qhuav etching yog raws li nram no: cov roj etching yog txhaj rau hauv lub tshuab nqus tsev cov tshuaj tiv thaiv chamber, thiab tom qab lub siab nyob rau hauv cov tshuaj tiv thaiv chamber yog stabilized, lub plasma yog generated los ntawm xov tooj cua zaus glow tawm; Tom qab raug cuam tshuam los ntawm high-speed electrons, nws decomposes los tsim dawb radicals, uas diffuse mus rau saum npoo ntawm substrate thiab yog adsorbed. Nyob rau hauv qhov kev txiav txim ntawm ion bombardment, cov adsorbed dawb radicals react nrog atom los yog molecules nyob rau saum npoo ntawm lub substrate los tsim gaseous byproducts, uas yog tawm los ntawm cov tshuaj tiv thaiv chamber. Cov txheej txheem tau qhia hauv daim duab hauv qab no:

Cov txheej txheem qhuav etching tuaj yeem muab faib ua plaub pawg hauv qab no:

(1)Lub cev sputtering etching: Nws tsuas yog tso siab rau lub zog ions hauv cov ntshav los txhawm rau txhawm rau saum npoo ntawm cov khoom etched. Tus naj npawb ntawm atoms sputtered nyob ntawm lub zog thiab lub kaum sab xis ntawm qhov teeb meem hais. Thaum lub zog thiab lub kaum sab xis tsis hloov, qhov sib txawv ntawm cov khoom sib txawv feem ntau txawv ntawm 2 mus rau 3 zaug, yog li tsis muaj kev xaiv. Cov txheej txheem tshuaj tiv thaiv feem ntau yog anisotropic.

(2)Tshuaj etching: Plasma muab cov pa roj-theem etching atoms thiab cov molecules, uas ua rau cov tshuaj lom neeg nrog rau cov khoom siv los tsim cov pa roj carbon monoxide. Cov tshuaj tiv thaiv ntshiab no muaj kev xaiv zoo thiab nthuav tawm cov yam ntxwv isotropic yam tsis xav txog cov qauv lattice.

Piv txwv li: Si (khoom) + 4F → SiF4 (gaseous), photoresist + O (gaseous) → CO2 (gaseous) + H2O (gaseous)

(3)Ion zog tsav etching: Ions yog ob qho tib si uas ua rau etching thiab lub zog nqa khoom. Lub etching efficiency ntawm xws li lub zog-carrying hais yog ntau tshaj ib qho kev txiav txim ntawm magnitude siab tshaj qhov yooj yim lub cev los yog tshuaj etching. Ntawm lawv, kev ua kom zoo ntawm lub cev thiab tshuaj tsis haum ntawm cov txheej txheem yog lub hauv paus ntawm kev tswj cov txheej txheem etching.

(4)Ion-barrier composite etching: Nws feem ntau yog hais txog lub cim ntawm polymer thaiv txheej tiv thaiv los ntawm cov khoom sib xyaw thaum lub sij hawm etching. Plasma xav tau cov txheej txheem tiv thaiv zoo li no los tiv thaiv cov tshuaj tiv thaiv etching ntawm sidewalls thaum lub sij hawm etching. Piv txwv li, ntxiv C rau Cl thiab Cl2 etching tuaj yeem tsim cov chlorocarbon compound txheej thaum etching los tiv thaiv cov phab ntsa los ntawm kev etched.

2.2.1 Qhuav tu

Kev ziab ziab feem ntau yog hais txog kev ntxuav plasma. Cov ions nyob rau hauv cov ntshav yog siv los bombard lub nto yuav tsum tau ntxuav, thiab lub atoms thiab molecules nyob rau hauv lub activated lub xeev muaj kev cuam tshuam nrog lub nto yuav tsum tau ntxuav, thiaj li mus tshem tawm thiab tshauv lub photoresist. Tsis zoo li qhuav etching, cov txheej txheem tsis tu ncua feem ntau tsis suav nrog cov kev taw qhia xaiv, yog li cov txheej txheem tsim tau yooj yim. Hauv cov txheej txheem ntau lawm, fluorine-based gases, oxygen lossis hydrogen feem ntau yog siv los ua lub cev tseem ceeb ntawm cov tshuaj tiv thaiv ntshav ntshav. Tsis tas li ntawd, ntxiv qee qhov nyiaj ntawm argon plasma tuaj yeem txhim kho cov nyhuv ion bombardment, yog li txhim kho kev tu kom zoo.

Hauv cov txheej txheem plasma qhuav tu, feem ntau siv tej thaj chaw deb plasma txoj kev. Qhov no yog vim hais tias nyob rau hauv cov txheej txheem ntxuav, nws yog cia siab tias yuav txo tau cov bombardment nyhuv ntawm ions nyob rau hauv lub plasma los tswj cov kev puas tsuaj los ntawm ion bombardment; thiab kev txhim kho cov tshuaj tiv thaiv ntawm cov tshuaj dawb radicals tuaj yeem txhim kho kev tu kom zoo. Cov ntshav tej thaj chaw deb tuaj yeem siv cov microwaves los tsim kom muaj qhov ruaj khov thiab siab dua cov tshuaj tiv thaiv kab mob uas nkag mus ua kom tiav cov tshuaj tiv thaiv kev ua kom huv. Feem ntau ntawm cov roj tu qhuav hauv kev lag luam siv cov roj fluorine-based gases, xws li NF3, thiab ntau dua 99% ntawm NF3 yog decomposed hauv microwave plasma. Yuav luag tsis muaj ion bombardment nyhuv nyob rau hauv cov txheej txheem ntxuav qhuav, yog li nws yog qhov zoo los tiv thaiv silicon wafer los ntawm kev puas tsuaj thiab txuas lub neej ntawm cov tshuaj tiv thaiv chamber.

Peb ntub etching thiab tu cov cuab yeej

3.1 Tank-hom wafer ntxuav tshuab

Lub tshuab ntxhua khaub ncaws-hom wafer yog tsim los ntawm lub hauv ntej-qhib wafer hloov lub thawv kis tau tus mob, lub wafer thauj khoom / tshem tawm cov kis tau tus mob, lub tshuab nqus cua nkag, cov tshuaj ua kua tank module, deionized dej tank module, lub tank kom qhuav. module thiab tswj module. Nws tuaj yeem ntxuav ntau lub thawv ntawm wafers tib lub sijhawm thiab tuaj yeem ua tiav qhuav-hauv thiab qhuav-tawm ntawm wafers.

3.2 Trench Wafer Etcher

3.3 Ib qho Wafer ntub cov khoom siv ua haujlwm

Raws li cov txheej txheem sib txawv, ib qho wafer ntub txheej txheem cov cuab yeej tuaj yeem muab faib ua peb pawg. Thawj qeb yog ib qho khoom siv tu wafer, uas nws lub hom phiaj tu muaj xws li hais, organic teeb meem, ntuj oxide txheej, hlau impurities thiab lwm yam kuab paug; qeb thib ob yog ib qho khoom siv wafer txhuam, uas nws lub hom phiaj tseem ceeb yog tshem tawm cov khoom ntawm qhov chaw ntawm wafer; qeb thib peb yog ib qho khoom siv wafer etching, uas yog siv los tshem tawm cov yeeb yaj kiab nyias. Raws li cov txheej txheem sib txawv, ib qho khoom siv wafer etching tuaj yeem muab faib ua ob hom. Thawj hom yog cov khoom siv etching me me, uas feem ntau yog siv los tshem tawm cov yeeb yaj kiab ua rau cov khaubncaws sab nraud povtseg tshwm sim los ntawm kev cog qoob loo ion zog; hom thib ob yog cov cuab yeej tshem tawm cov txheej txheem, uas yog siv los tshem tawm cov txheej txheem thaiv tom qab wafer thinning lossis tshuaj kho tshuab polishing.

Los ntawm kev xav ntawm tag nrho cov tshuab architecture, lub hauv paus architecture ntawm tag nrho cov hom ntawm ib leeg-wafer ntub txheej txheem cov cuab yeej zoo sib xws, feem ntau muaj 6 qhov chaw: lub ntsiab ncej, wafer hloov system, chamber module, tshuaj kua kua thiab hloov module, software system. thiab hluav taws xob tswj module.

3.4 Ib qho Wafer Cleaning Equipment

Cov khoom siv tu ib leeg yog tsim los ntawm RCA cov txheej txheem tu ib txwm, thiab nws lub hom phiaj yog los ntxuav cov khoom, organic teeb meem, ntuj oxide txheej, hlau impurities thiab lwm yam pa phem. Nyob rau hauv cov nqe lus ntawm cov txheej txheem daim ntawv thov, ib tug wafer tu cov cuab yeej yog tam sim no dav siv nyob rau hauv pem hauv ntej-kawg thiab rov qab-kawg txheej txheem ntawm integrated circuit manufacturing, xws li ntxuav ua ntej thiab tom qab tsim zaj duab xis, ntxuav tom qab plasma etching, ntxuav tom qab ion implantation, ntxuav tom qab tshuaj. mechanical polishing, thiab tu tom qab hlau deposition. Tsuas yog rau cov txheej txheem kub phosphoric acid, ib qho wafer tu cov cuab yeej yog qhov sib xws nrog txhua txoj kev tu.

3.5 Ib qho Wafer Etching Khoom

Cov txheej txheem lub hom phiaj ntawm ib qho wafer etching khoom yog tsuas yog nyias zaj duab xis etching. Raws li cov txheej txheem lub hom phiaj, nws tuaj yeem muab faib ua ob pawg, uas yog, lub teeb etching cov cuab yeej (siv tshem tawm cov txheej txheem kev puas tsuaj los ntawm cov khoom siv hluav taws xob ion implantation) thiab cov cuab yeej tshem tawm cov txheej txheem (siv tshem tawm cov txheej txheem thaiv tom qab wafer. thinning lossis chemical mechanical polishing). Cov ntaub ntawv uas yuav tsum tau muab tshem tawm hauv cov txheej txheem feem ntau muaj xws li silicon, silicon oxide, silicon nitride thiab hlau zaj duab xis txheej.

Plaub qhuav etching thiab tu cov cuab yeej

4.1 Kev faib tawm ntawm cov khoom siv plasma etching

Ntxiv nrog rau ion sputtering etching cov cuab yeej uas nyob ze rau cov tshuaj tiv thaiv lub cev ntshiab thiab cov khoom siv degumming uas nyob ze rau cov tshuaj tiv thaiv tshuaj dawb huv, plasma etching tuaj yeem raug faib ua ob pawg raws li qhov sib txawv plasma tiam thiab tswj technologies:

- Capacitively Coupled Plasma (CCP) etching;

-Inductively Coupled Plasma (ICP) etching.

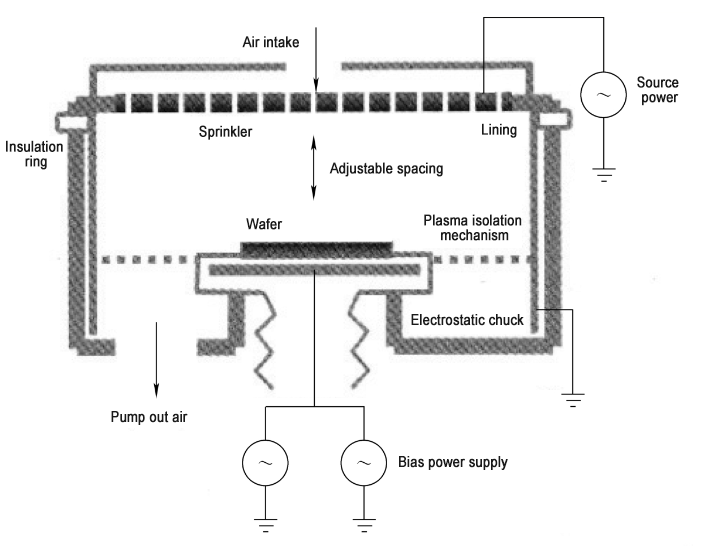

4.1.1 TSI

Capacitively coupled plasma etching yog txuas lub xov tooj cua zaus fais fab mov rau ib los yog ob qho tib si ntawm lub sab sauv thiab qis electrodes nyob rau hauv cov tshuaj tiv thaiv chamber, thiab cov plasma ntawm ob daim hlau ua ib tug capacitor nyob rau hauv ib tug yooj yim sib npaug Circuit Court.

Muaj ob lub technologies ntxov tshaj plaws:

Ib qho yog plasma etching thaum ntxov, uas txuas RF fais fab mov mus rau sab sauv electrode thiab qis electrode qhov twg wafer nyob hauv av. Vim tias cov plasma generated nyob rau hauv txoj kev no yuav tsis tsim ib tug txaus tuab ion sheath nyob rau saum npoo ntawm lub wafer, lub zog ntawm ion bombardment yog tsawg, thiab nws yog feem ntau siv nyob rau hauv cov txheej txheem xws li silicon etching uas siv active hais raws li lub ntsiab etchant.

Lwm qhov yog qhov ua kom muaj zog ion etching thaum ntxov (RIE), uas txuas lub RF fais fab mov mus rau qis electrode qhov twg lub wafer nyob, thiab thaj av sab sauv electrode nrog thaj tsam loj. Cov thev naus laus zis no tuaj yeem tsim cov ion tuab tuab, uas yog tsim rau cov txheej txheem dielectric etching uas yuav tsum muaj zog ion ntau dua los koom nrog cov tshuaj tiv thaiv. Nyob rau hauv lub hauv paus ntawm thaum ntxov reactive ion etching, ib tug DC magnetic teb perpendicular rau lub RF hluav taws xob teb yog ntxiv rau daim ntawv ExB drift, uas yuav ua rau kom muaj kev sib tsoo ntawm electrons thiab roj hais, li no zoo txhim kho cov ntshav concentration thiab etching tus nqi. Qhov etching no yog hu ua magnetic field enhanced reactive ion etching (MERIE).

Peb cov thev naus laus zis saum toj no muaj qhov tsis zoo, uas yog, cov ntshav plasma concentration thiab nws lub zog tsis tuaj yeem tswj tau nyias. Piv txwv li, nyob rau hauv thiaj li yuav nce tus nqi etching, tus txheej txheem ntawm kev nce cov ntshav hluav taws xob, tab sis nce cov pa hluav taws xob yuav ua rau muaj kev puas tsuaj rau hauv ion zog, uas yuav ua rau muaj kev puas tsuaj rau lub wafer. Nyob rau hauv lub xyoo caum dhau los, capacitive coupling technology tau txais ib tug tsim ntawm ntau yam RF qhov chaw, uas yog txuas nrog rau sab sauv thiab sab electrodes raws li los yog ob qho tib si rau lub qis electrode.

Los ntawm kev xaiv thiab sib txuam sib txawv RF zaus, thaj tsam electrode, qhov sib nrug, cov ntaub ntawv thiab lwm yam tsis tseem ceeb yog kev sib koom ua ke, cov plasma concentration thiab ion zog tuaj yeem raug txiav kom ntau li ntau tau.

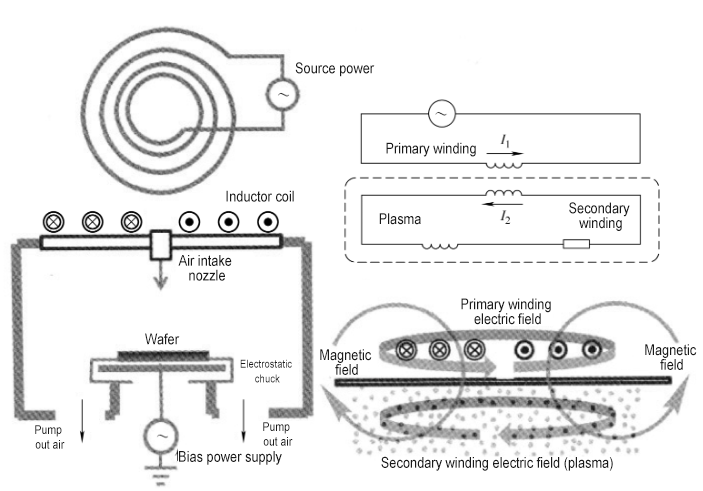

4.1.2 TSI

Inductively coupled plasma etching yog tso ib lossis ntau pawg ntawm coils txuas nrog lub xov tooj cua zaus fais fab mov ntawm lossis ib ncig ntawm cov tshuaj tiv thaiv chamber. Qhov chaw sib nqus sib nqus uas tsim los ntawm lub xov tooj cua zaus tam sim no hauv lub kauj nkag mus rau hauv cov tshuaj tiv thaiv chamber los ntawm lub qhov rais dielectric kom nrawm cov electrons, yog li tsim cov ntshav plasma. Nyob rau hauv ib qho yooj yim sib npaug Circuit Court (transformer), lub kauj yog thawj winding inductance, thiab cov ntshav yog qhov thib ob winding inductance.

Txoj kev sib txuas no tuaj yeem ua tiav cov ntshav plasma uas ntau dua ib qho kev txiav txim siab ntau dua li qhov kev sib txuas capacitive ntawm qhov tsis tshua muaj siab. Tsis tas li ntawd, qhov thib ob RF fais fab mov txuas nrog rau qhov chaw ntawm lub wafer raws li kev tsis ncaj ncees lub zog muab ion bombardment zog. Yog li ntawd, ion concentration nyob ntawm qhov chaw fais fab mov ntawm lub kauj thiab lub zog ion nyob ntawm qhov tsis ncaj ncees lawm, yog li ua tiav qhov kev txiav txim siab ntau dua ntawm cov concentration thiab lub zog.

4.2 Plasma Etching khoom

Yuav luag tag nrho cov etchants nyob rau hauv qhuav etching yog ncaj qha los yog indirectly generated los ntawm plasma, yog li qhuav etching feem ntau hu ua plasma etching. Plasma etching yog ib hom plasma etching hauv kev nkag siab dav. Nyob rau hauv ob qho tib si thaum ntxov flat-phaj reactor tsim, ib qho yog rau hauv av lub phaj qhov twg lub wafer nyob thiab lwm phaj txuas nrog RF qhov chaw; lwm tus yog qhov opposite. Hauv kev tsim yav dhau los, thaj tsam ntawm cov phaj hauv av feem ntau loj dua qhov chaw ntawm lub phaj txuas nrog RF qhov chaw, thiab cov pa roj hauv lub reactor siab. Lub ion sheath tsim nyob rau saum npoo ntawm lub wafer yog nyias, thiab lub wafer zoo li "immersed" nyob rau hauv plasma. Etching feem ntau ua tiav los ntawm cov tshuaj tiv thaiv ntawm cov khoom nquag hauv cov ntshav thiab cov khoom siv etched. Lub zog ntawm ion bombardment yog tsawg heev, thiab nws txoj kev koom tes hauv etching yog tsawg heev. Qhov kev tsim no hu ua plasma etching hom. Hauv lwm qhov kev tsim, vim tias qib kev koom tes ntawm ion bombardment yog qhov loj, nws hu ua reactive ion etching hom.

4.3 Reactive Ion Etching Khoom

Reactive ion etching (RIE) yog hais txog cov txheej txheem etching uas cov khoom nquag thiab cov ions raug nqi koom nrog hauv cov txheej txheem tib lub sijhawm. Ntawm lawv, cov khoom ua haujlwm feem ntau yog cov khoom nruab nrab (tseem hu ua dawb radicals), nrog rau siab concentration (li 1% mus rau 10% ntawm cov roj concentration), uas yog cov khoom tseem ceeb ntawm cov etchant. Cov khoom tsim los ntawm cov tshuaj tiv thaiv ntawm lawv thiab cov khoom etched yog volatilized thiab ncaj qha rho tawm los ntawm cov tshuaj tiv thaiv chamber, los yog accumulated nyob rau hauv etched nto; Thaum cov ions raug nqi qis dua (10-4 mus rau 10-3 ntawm cov roj concentration), thiab lawv tau nrawm nrawm los ntawm cov hluav taws xob hluav taws xob ntawm cov ion sheath tsim rau ntawm qhov chaw ntawm lub wafer kom tawg lub etched nto. Muaj ob lub luag haujlwm tseem ceeb ntawm cov khoom siv hluav taws xob. Ib qho yog txhawm rau rhuav tshem cov qauv atomic ntawm cov khoom siv etched, yog li ua kom tus nqi ntawm cov khoom nquag ua rau nws; lwm qhov yog los foob pob thiab tshem tawm cov khoom sib xyaw ua ke kom cov khoom siv etched nyob rau hauv tag nrho kev sib cuag nrog cov khoom nquag, kom cov etching txuas ntxiv.

Vim hais tias ions tsis ncaj qha koom rau hauv cov tshuaj tiv thaiv etching (los yog account rau ib qho me me, xws li kev tshem tawm ntawm lub cev thiab cov tshuaj etching ncaj qha ntawm cov ions nquag), nruj me ntsis hais lus, cov txheej txheem saum toj no etching yuav tsum hu ua ion-pab etching. Lub npe reactive ion etching tsis raug, tab sis nws tseem siv niaj hnub no. Cov cuab yeej RIE ntxov tshaj plaws tau muab tso rau hauv kev siv hauv xyoo 1980s. Vim yog siv ib qho RF fais fab mov thiab ib qho yooj yim cov tshuaj tiv thaiv chamber tsim, nws muaj kev txwv nyob rau hauv cov nqe lus ntawm etching tus nqi, uniformity thiab selectivity.

4.4 Magnetic Field Enhanced Reactive Ion Etching Khoom

MERIE (Magnetically Enhanced Reactive Ion Etching) ntaus ntawv yog ib qho khoom siv etching uas yog tsim los ntawm kev ntxiv DC magnetic teb rau lub tiaj tiaj RIE ntaus ntawv thiab yog npaj kom nce tus nqi etching.

MERIE cov cuab yeej tau muab tso rau hauv kev siv loj hauv xyoo 1990s, thaum ib qho khoom siv wafer etching tau dhau los ua cov khoom siv tseem ceeb hauv kev lag luam. Qhov loj tshaj qhov tsis zoo ntawm MERIE cov cuab yeej yog qhov sib txawv ntawm qhov tsis sib xws ntawm cov ntshav plasma concentration tshwm sim los ntawm cov hlau nplaum yuav ua rau muaj qhov sib txawv tam sim no lossis qhov sib txawv ntawm cov khoom siv hluav taws xob sib txuas, yog li ua rau cov cuab yeej puas. Txij li qhov kev puas tsuaj no tshwm sim los ntawm qhov tsis sib xws tam sim ntawd, kev sib hloov ntawm cov hlau nplaum tsis tuaj yeem tshem tawm nws. Raws li qhov loj ntawm kev sib xyaw ua ke txuas ntxiv zuj zus, lawv cov cuab yeej puas tsuaj tau nce siab rau cov ntshav plasma inhomogeneity, thiab cov thev naus laus zis ntawm kev nce tus nqi etching los ntawm kev txhim kho cov hlau nplaum tau maj mam hloov los ntawm ntau lub RF fais fab mov planar reactive ion etching tshuab, uas. yog, capacitively txuas plasma etching tshuab.

4.5 Capacitively coupled plasma etching khoom

Capacitively coupled plasma (CCP) etching cov cuab yeej yog ib yam khoom uas tsim cov ntshav nyob rau hauv cov tshuaj tiv thaiv chamber los ntawm capacitive coupling los ntawm kev siv lub xov tooj cua zaus (los yog DC) fais fab mov rau lub phaj electrode thiab siv rau etching. Nws txoj cai etching zoo ib yam li cov khoom siv reactive ion etching.

Daim duab yooj yim schematic ntawm CCP etching khoom yog qhia hauv qab no. Nws feem ntau siv ob lossis peb qhov RF ntawm cov zaus sib txawv, thiab qee qhov kuj siv DC fais fab mov. Qhov zaus ntawm RF fais fab mov yog 800kHz ~ 162MHz, thiab cov khoom siv feem ntau yog 2MHz, 4MHz, 13MHz, 27MHz, 40MHz thiab 60MHz. RF fais fab khoom siv nrog zaus ntawm 2MHz lossis 4MHz feem ntau hu ua RF qhov chaw qis. Lawv feem ntau txuas nrog rau qis electrode qhov twg wafer nyob. Lawv muaj txiaj ntsig zoo hauv kev tswj cov ion zog, yog li lawv tseem hu ua cov khoom siv hluav taws xob tsis zoo; RF fais fab mov uas muaj zaus tshaj 27MHz yog hu ua high-frequency RF qhov chaw. Lawv tuaj yeem txuas nrog rau sab sauv electrode lossis qis electrode. Lawv muaj txiaj ntsig zoo hauv kev tswj cov ntshav plasma, yog li lawv tseem hu ua cov khoom siv hluav taws xob. Lub 13MHz RF fais fab mov yog nyob rau hauv nruab nrab thiab feem ntau suav hais tias muaj ob qho tib si ntawm cov haujlwm saum toj no tab sis kuj tsis muaj zog. Nco ntsoov tias txawm hais tias cov ntshav plasma concentration thiab lub zog tuaj yeem hloov kho nyob rau hauv qee qhov ntau los ntawm lub zog ntawm RF qhov chaw sib txawv (hu ua decoupling effect), vim cov yam ntxwv ntawm kev sib txuas capacitive, lawv tsis tuaj yeem hloov kho thiab tswj nws tus kheej kiag li.

Lub zog faib ntawm ions muaj qhov cuam tshuam loj rau cov ncauj lus kom ntxaws ntawm etching thiab kev puas tsuaj ntawm cov cuab yeej, yog li kev txhim kho thev naus laus zis los ua kom zoo dua ion zog faib tau dhau los ua ib qho ntawm cov ntsiab lus tseem ceeb ntawm cov khoom siv etching siab heev. Tam sim no, cov thev naus laus zis uas tau ua tiav hauv kev tsim khoom suav nrog ntau lub RF hybrid tsav, DC superposition, RF ua ke nrog DC pulse bias, thiab synchronous pulsed RF tso tawm ntawm kev tsis ncaj ncees lub zog thiab cov khoom siv hluav taws xob.

CCP etching khoom yog ib qho ntawm ob hom kev siv ntau tshaj plaws ntawm cov khoom siv plasma etching. Nws yog tsuas yog siv nyob rau hauv cov txheej txheem etching ntawm dielectric cov ntaub ntawv, xws li lub rooj vag sidewall thiab nyuaj daim npog qhov ncauj etching nyob rau hauv pem hauv ntej theem ntawm logic nti txheej txheem, hu rau lub qhov etching nyob rau hauv nruab nrab theem, mosaic thiab txhuas pad etching nyob rau hauv lub rov qab theem, raws li zoo raws li etching ntawm qhov sib sib zog nqus trenches, qhov sib sib zog nqus qhov thiab thaiv qhov sib tiv tauj hauv 3D flash nco nti txheej txheem (siv silicon nitride / silicon oxide qauv ua piv txwv).

Muaj ob qhov teeb meem tseem ceeb thiab cov lus qhia txhim kho tau ntsib los ntawm CCP etching cov cuab yeej. Ua ntej, nyob rau hauv daim ntawv thov ntawm tsis tshua muaj siab ion zog, etching muaj peev xwm ntawm high nam piv qauv (xws li lub qhov thiab zawj etching ntawm 3D flash nco yuav tsum tau ib tug ratio siab tshaj 50: 1). Txoj kev tam sim no ntawm kev ua kom lub zog tsis zoo los ua kom lub zog ion tau siv RF cov khoom siv hluav taws xob txog li 10,000 watts. Nyob rau hauv qhov kev pom ntawm qhov loj ntawm cov cua kub generated, qhov txias thiab kub tswj tshuab ntawm cov tshuaj tiv thaiv chamber yuav tsum tau txhim kho tas li. Qhov thib ob, yuav tsum muaj kev sib tw hauv kev tsim cov roj etching tshiab los daws qhov teeb meem ntawm kev muaj peev xwm etching.

4.6 Inductively Coupled Plasma Etching Khoom

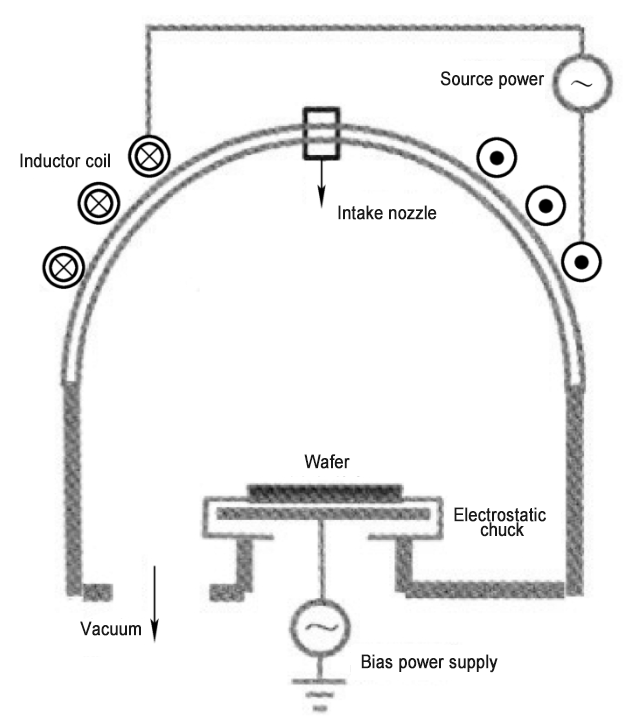

Inductively coupled plasma (ICP) etching cov cuab yeej yog ib qho cuab yeej uas sib txuas lub zog ntawm lub xov tooj cua zaus lub zog mus rau hauv cov tshuaj tiv thaiv chamber nyob rau hauv daim ntawv ntawm magnetic teb ntawm inductor coil, yog li tsim cov ntshav rau etching. Nws txoj ntsiab cai etching kuj yog rau qhov dav dav reactive ion etching.

Muaj ob lub ntsiab ntawm cov ntshav plasma tsim rau ICP etching khoom. Ib qho yog transformer coupled plasma (TCP) technology tsim thiab tsim los ntawm Lam Research. Nws inductor kauj yog muab tso rau ntawm lub dielectric qhov rais dav hlau saum toj no cov tshuaj tiv thaiv chamber. 13.56MHz RF teeb liab tsim ib qho chaw sib nqus sib nqus nyob rau hauv lub kauj uas yog perpendicular rau lub qhov rais dielectric thiab radially diverges nrog lub kauj axis ua qhov chaw.

Lub magnetic teb nkag mus rau hauv cov tshuaj tiv thaiv chamber los ntawm lub dielectric qhov rais, thiab lub alternating magnetic teb generates ib tug alternating hluav taws xob teb thaum uas tig mus rau lub dielectric qhov rais nyob rau hauv cov tshuaj tiv thaiv chamber, yog li ua tiav cov dissociation ntawm cov etching roj thiab generating plasma. Txij li thaum lub hauv paus ntsiab lus no tuaj yeem nkag siab tias yog lub tshuab hloov pauv nrog lub inductor coil ua lub hauv paus winding thiab cov ntshav hauv cov tshuaj tiv thaiv chamber raws li qhov thib ob winding, ICP etching muaj npe tom qab qhov no.

Lub ntsiab kom zoo dua ntawm TCP thev naus laus zis yog cov qauv yooj yim los ntsuas. Piv txwv li, los ntawm 200mm wafer mus rau 300mm wafer, TCP tuaj yeem tswj tau cov nyhuv tib yam los ntawm kev nce qhov loj ntawm lub kauj.

Lwm qhov kev tsim cov ntshav plasma yog decoupled plasma source (DPS) technology tsim thiab tsim los ntawm Applied Materials, Inc. ntawm Tebchaws Meskas. Nws inductor kauj yog peb-dimensionally raug mob ntawm lub qhov rais hemispherical dielectric. Lub hauv paus ntsiab lus ntawm kev tsim cov ntshav plasma zoo ib yam li cov thev naus laus zis TCP tau hais tseg, tab sis cov pa roj dissociation efficiency yog qhov siab, uas yog qhov tsim nyog kom tau txais cov ntshav plasma ntau dua.

Txij li qhov ua tau zoo ntawm inductive coupling los tsim cov ntshav plasma yog siab dua li ntawm capacitive coupling, thiab cov plasma feem ntau yog tsim nyob rau hauv cheeb tsam ze ntawm lub qhov rais dielectric, nws cov plasma concentration yog qhov pib txiav txim siab los ntawm lub zog ntawm cov khoom siv hluav taws xob txuas nrog lub inductor. coil, thiab lub zog ion nyob rau hauv lub ion sheath nyob rau saum npoo ntawm lub wafer yog yeej txiav txim siab los ntawm lub hwj chim ntawm lub bias fais fab mov, yog li ntawd lub concentration thiab lub zog ntawm lub wafer. ions tuaj yeem tswj tau ntawm nws tus kheej, yog li ua tiav decoupling.

ICP etching khoom yog ib qho ntawm ob hom kev siv ntau tshaj plaws ntawm cov khoom siv plasma etching. Nws yog tsuas yog siv rau etching ntawm silicon ntiav trenches, germanium (Ge), polysilicon rooj vag lug, hlau rooj vag lug, strained silicon (Strained-Si), hlau xov hlau, hlau pads (Pads), mosaic etching hlau hard masks thiab ntau yam txheej txheem nyob rau hauv ntau yam imaging technology.

Tsis tas li ntawd, nrog kev nce ntawm peb-dimensional integrated circuits, CMOS duab sensors thiab micro-electro-mechanical systems (MEMS), nrog rau kev nce ceev hauv daim ntawv thov ntawm silicon vias (TSV), qhov loj-loj oblique qhov thiab sib sib zog nqus silicon etching nrog txawv morphologies, ntau manufacturers tau launched etching khoom tsim tshwj xeeb rau cov kev siv. Nws cov yam ntxwv yog qhov loj etching qhov tob (tsawg lossis ntau pua microns), yog li nws feem ntau ua haujlwm nyob rau hauv cov pa roj siab, siab siab thiab siab zog.

———————————————————————————————————————————————————————— ————————————————

Semicera tuaj yeem muab taugraphite qhov chaw, soft/rigid xav, silicon carbide qhov chaw, CVD silicon carbide qhov chaw, thiabSiC/TaC coated qhov chawnrog hauv 30 hnub.

Yog tias koj txaus siab rau cov khoom lag luam semiconductor saum toj no,thov tsis txhob yig tiv tauj peb thawj zaug.

Tel: +86-13373889683

WhatsApp: +86-15957878134

Email: sales01@semi-cera.com

Post lub sij hawm: Aug-31-2024