1. Taw qhia

Ion implantation yog ib qho ntawm cov txheej txheem tseem ceeb hauv kev tsim hluav taws xob sib txuas. Nws yog hais txog cov txheej txheem ntawm kev ua kom lub ion beam mus rau ib lub zog (feem ntau nyob rau hauv qhov ntau ntawm keV rau MeV) thiab tom qab ntawd txhaj nws mus rau saum npoo ntawm cov khoom siv los hloov lub cev lub cev ntawm cov khoom. Nyob rau hauv cov txheej txheem kev sib xyaw ua ke, cov khoom siv feem ntau yog silicon, thiab cov implanted impurity ions feem ntau yog boron ions, phosphorus ions, arsenic ions, indium ions, germanium ions, thiab lwm yam. khoom siv los yog tsim ib qho kev sib tshuam PN. Thaum qhov loj me ntawm kev sib xyaw ua ke raug txo mus rau lub sijhawm sub-micron, cov txheej txheem ion implantation tau dav siv.

Nyob rau hauv cov txheej txheem kev tsim hluav taws xob sib txuas, ion implantation feem ntau yog siv rau cov txheej faus sib sib zog nqus, rov qab doped qhov dej, qhov pib voltage hloov, qhov chaw thiab qhov dej txuas ntxiv implantation, qhov chaw thiab tso dej cog, polysilicon rooj vag doping, tsim PN junctions thiab resistors / capacitors, thiab lwm yam. Nyob rau hauv tus txheej txheem ntawm kev npaj cov ntaub ntawv silicon substrate ntawm insulators, faus oxide txheej yog tsim los ntawm high-concentration oxygen ion implantation, los yog ntse txiav yog tiav los ntawm high-concentration hydrogen ion implantation.

Ion implantation yog ua los ntawm ion implanter, thiab nws cov txheej txheem tseem ceeb tshaj plaws yog koob tshuaj thiab lub zog: cov koob tshuaj txiav txim siab qhov kawg concentration, thiab lub zog txiav txim siab ntau yam (piv txwv li, qhov tob) ntawm cov ions. Raws li kev tsim cov cuab yeej sib txawv, cov kev cog qoob loo tau muab faib ua cov koob tshuaj siab zog, nruab nrab koob tshuaj nruab nrab-zog, nruab nrab-dose low-zog, lossis high-dose low-zog. Txhawm rau kom tau txais cov txiaj ntsig zoo tshaj plaws implantation, cov implanters sib txawv yuav tsum tau nruab rau cov txheej txheem sib txawv.

Tom qab ion implantation, feem ntau yuav tsum tau mus rau qhov kub-kub annealing txheej txheem los kho cov lattice puas los ntawm ion implantation thiab qhib impurity ions. Hauv cov txheej txheem kev sib xyaw ua ke ib txwm muaj, txawm hais tias qhov ntsuas kub annealing muaj qhov cuam tshuam zoo rau doping, qhov kub ntawm cov txheej txheem ion implantation nws tus kheej tsis tseem ceeb. Ntawm cov txheej txheem thev naus laus zis hauv qab 14nm, qee qhov txheej txheem ion implantation yuav tsum tau ua nyob rau hauv qhov chaw qis lossis kub kub los hloov qhov cuam tshuam ntawm lattice puas, thiab lwm yam.

2. txheej txheem ion implantation

2.1 Cov Ntsiab Cai

Ion implantation yog cov txheej txheem doping tsim nyob rau xyoo 1960s uas zoo tshaj rau cov txheej txheem diffusion hauv ntau yam.

Qhov sib txawv tseem ceeb ntawm ion implantation doping thiab tsoos diffusion doping yog raws li nram no:

(1) Kev faib tawm ntawm impurity concentration hauv thaj av doped yog txawv. Lub ncov impurity concentration ntawm ion implantation yog nyob rau hauv lub siv lead ua, thaum lub ncov impurity concentration ntawm diffusion yog nyob rau saum npoo ntawm siv lead ua. (2) Ion implantation yog txheej txheem ua haujlwm ntawm chav tsev kub lossis txawm tias kub qis, thiab lub sijhawm tsim khoom luv luv. Diffusion doping xav tau kev kho mob ntev dua. (3) Ion implantation tso cai rau hloov tau yooj yim thiab meej xaiv ntawm cov khoom cog. (4) Txij li cov impurities raug cuam tshuam los ntawm thermal diffusion, lub waveform tsim los ntawm ion implantation nyob rau hauv lub siv lead ua yog zoo dua lub waveform tsim los ntawm diffusion nyob rau hauv lub siv lead ua. (5) Ion implantation feem ntau tsuas yog siv photoresist raws li cov khoom siv lub npog ntsej muag, tab sis diffusion doping yuav tsum muaj kev loj hlob lossis tso tawm ntawm cov yeeb yaj kiab ntawm qee qhov tuab raws li daim npog ntsej muag. (6) Ion implantation tau hloov pauv hloov pauv thiab dhau los ua cov txheej txheem doping tseem ceeb hauv kev tsim cov khoom sib xyaw ua ke niaj hnub no.

Thaum muaj teeb meem ion beam nrog qee lub zog foob pob lub hom phiaj (feem ntau yog wafer), cov ions thiab cov atoms ntawm lub hom phiaj saum npoo yuav ua rau muaj ntau yam kev sib cuam tshuam, thiab hloov lub zog mus rau lub hom phiaj atoms nyob rau hauv ib txoj kev zoo siab los yog ionize. lawv. Cov ions tseem tuaj yeem poob qee lub zog los ntawm lub zog hloov pauv, thiab thaum kawg yuav tawg los ntawm lub hom phiaj atoms lossis nres hauv cov khoom siv. Yog tias cov ions txhaj tshuaj hnyav dua, feem ntau ntawm cov ions yuav raug txhaj rau hauv lub hom phiaj. Ntawm qhov tsis sib xws, yog tias cov ions txhaj tshuaj sib dua, ntau qhov kev txhaj tshuaj ions yuav thaws tawm ntawm lub hom phiaj nto. Yeej, cov hluav taws xob siab ions txhaj rau hauv lub hom phiaj yuav sib tsoo nrog cov lattice atoms thiab cov hluav taws xob hauv cov phiaj xwm sib txawv. Ntawm lawv, kev sib tsoo ntawm ions thiab cov phiaj xwm atoms tuaj yeem suav tias yog kev sib tsoo elastic vim tias lawv nyob ze rau hauv pawg.

2.2 Cov tsis tseem ceeb ntawm ion implantation

Ion implantation yog ib txoj kev hloov tau yooj yim uas yuav tsum tau ua kom tau raws li cov qauv tsim thiab cov khoom tsim tawm. Qhov tseem ceeb ion implantation tsis yog: koob tshuaj, ntau yam.

Dose (D) yog hais txog tus naj npawb ntawm ions txhaj rau ib cheeb tsam ntawm silicon wafer nto, hauv atoms ib square centimeter (los yog ions ib square centimeter). D tuaj yeem xam los ntawm cov qauv hauv qab no:

Qhov twg D yog qhov koob tshuaj implantation (tus naj npawb ntawm ions/unit cheeb tsam); t yog lub sij hawm implantation; Kuv yog lub beam tam sim no; q yog tus nqi nqa los ntawm ion (ib qho nqi yog 1.6 × 1019C[1]); thiab S yog qhov chaw cog qoob loo.

Ib qho ntawm cov laj thawj tseem ceeb vim li cas ion implantation tau dhau los ua cov cuab yeej tseem ceeb hauv kev tsim khoom silicon wafer yog tias nws tuaj yeem rov cog cov tib koob tshuaj impurities rau hauv silicon wafers. Lub implanter ua tiav lub hom phiaj no nrog kev pab los ntawm tus nqi zoo ntawm cov ions. Thaum qhov zoo impurity ions tsim ib qho ion beam, nws cov nqi ntws yog hu ua ion beam tam sim no, uas yog ntsuas hauv mA. Qhov ntau ntawm nruab nrab thiab qis tam sim no yog 0.1 txog 10 mA, thiab qhov ntau ntawm cov tam sim no siab yog 10 mus rau 25 mA.

Qhov loj ntawm ion beam tam sim no yog qhov hloov pauv tseem ceeb hauv kev txhais cov koob tshuaj. Yog tias qhov tam sim no nce, tus naj npawb ntawm impurity atoms implanted ib chav tsev lub sij hawm kuj nce. Cov tam sim no siab yog qhov tsim nyog rau kev nce silicon wafer tawm los (txhaj tshuaj ntau dua rau ib lub sijhawm tsim khoom), tab sis nws kuj ua rau muaj teeb meem sib xws.

3. ion implantation khoom

3.1 Cov Qauv Txheej Txheem

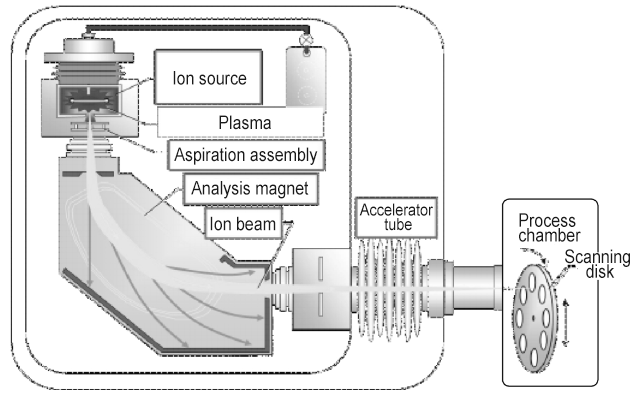

Ion implantation cov cuab yeej suav nrog 7 qhov yooj yim modules:

① ion qhov chaw thiab absorber;

② loj analyzer (xws li analytical hlau nplaum);

③ accelerator raj;

④ scanning disk;

⑤ electrostatic neutralization system;

⑥ txheej txheem chamber;

⑦ koob tshuaj tswj qhov system.

All modules yog nyob rau hauv ib puag ncig lub tshuab nqus tsev tsim los ntawm lub tshuab nqus tsev. Daim duab kos duab yooj yim ntawm ion implanter yog qhia hauv daim duab hauv qab no.

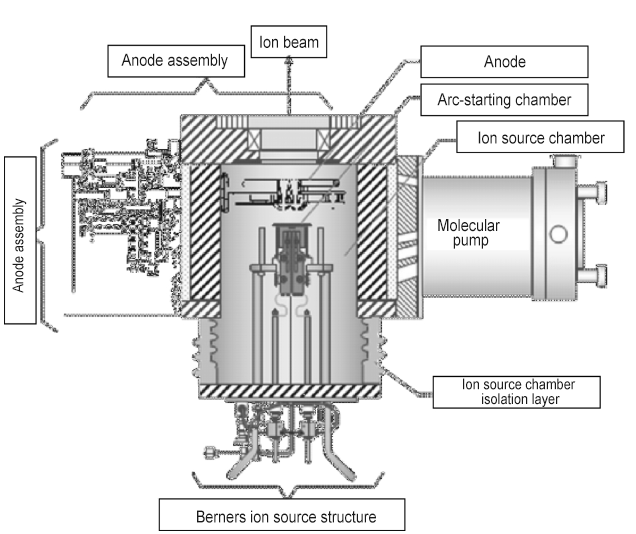

(1)Ion qhov chaw:

Feem ntau nyob rau hauv tib lub tshuab nqus tsev chamber raws li lub tshuab nqus tsev electrode. Cov impurities tos txhaj tshuaj yuav tsum muaj nyob rau hauv lub xeev ion thiaj li yuav tau tswj thiab ceev los ntawm hluav taws xob teb. Feem ntau siv B +, P +, As +, thiab lwm yam yog tau los ntawm ionizing atoms lossis molecules.

Cov khoom siv impurity siv yog BF3, PH3 thiab AsH3, thiab lwm yam, thiab lawv cov qauv tau qhia hauv daim duab hauv qab no. Cov electrons tso tawm los ntawm filament sib tsoo nrog roj atoms los tsim ions. Cov hluav taws xob feem ntau yog tsim los ntawm qhov chaw kub tungsten filament. Piv txwv li, lub Berners ion qhov chaw, lub cathode filament yog ntsia rau hauv ib tug arc chamber nrog ib tug roj inlet. Sab hauv phab ntsa ntawm lub arc chamber yog lub anode.

Thaum cov pa roj tau qhia, cov tam sim no loj dhau los ntawm cov filament, thiab qhov hluav taws xob ntawm 100 V yog siv los ntawm qhov zoo thiab qhov tsis zoo electrodes, uas yuav tsim hluav taws xob hluav taws xob nyob ib ncig ntawm lub filament. Cov ions zoo yog tsim tom qab cov hluav taws xob hluav taws xob siab sib tsoo nrog cov pa roj molecules.

Cov hlau nplaum sab nraud siv cov hlau nplaum sib nqus ua ke mus rau cov filament kom ionization thiab stabilize cov ntshav. Nyob rau hauv lub arc chamber, nyob rau lwm yam kawg ntawm lub filament, muaj ib tug tsis zoo them nqi reflector uas qhia cov electrons rov qab los txhim kho tiam thiab efficiency ntawm electrons.

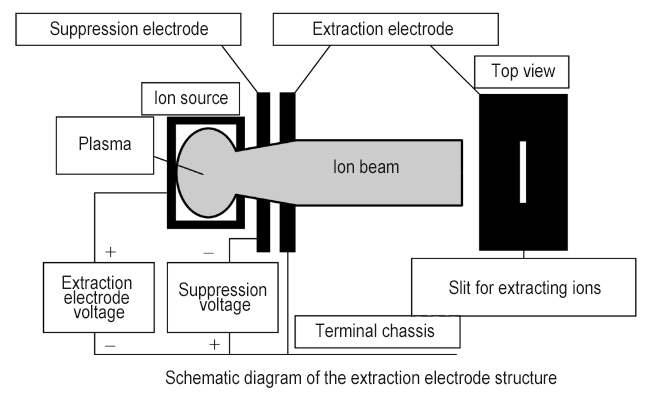

(2)Kev nqus:

Nws yog siv los sau cov ions zoo tsim nyob rau hauv arc chamber ntawm ion qhov chaw thiab tsim lawv rau hauv ib qho ion beam. Txij li thaum lub arc chamber yog lub anode thiab cov cathode yog tsis zoo pressurized ntawm lub suction electrode, lub hluav taws xob teb generated tswj cov ions zoo, ua rau lawv txav mus rau lub suction electrode thiab raug rho tawm ntawm lub ion slit, raws li qhia nyob rau hauv daim duab hauv qab no. . Lub zog hluav taws xob ntau dua, lub zog kinetic ntau dua qhov ions nce tom qab acceleration. Kuj tseem muaj qhov hluav taws xob hluav taws xob ntawm lub tshuab nqus hluav taws xob los tiv thaiv kev cuam tshuam los ntawm electrons hauv cov ntshav. Nyob rau tib lub sijhawm, cov hluav taws xob hluav taws xob tuaj yeem tsim cov ions rau hauv ib qho ion beam thiab tsom lawv mus rau hauv ib qho kev sib luag ion beam kwj kom nws dhau los ntawm cov khoom cog.

(3)Mass analyzer:

Tej zaum yuav muaj ntau hom ions tsim los ntawm ion qhov chaw. Nyob rau hauv lub acceleration ntawm lub anode voltage, cov ions txav ntawm ib tug ceev ceev. Cov ions sib txawv muaj qhov sib txawv ntawm cov atomic mass units thiab txawv qhov sib txawv ntawm qhov sib txawv.

(4)Accelerator raj:

Yuav kom tau txais kev nrawm dua, yuav tsum muaj lub zog ntau dua. Ntxiv rau qhov chaw hluav taws xob muab los ntawm anode thiab huab hwm coj tsom xam, ib qho hluav taws xob uas muab rau hauv lub raj accelerator kuj tseem yuav tsum tau ua kom nrawm. Lub accelerator raj muaj ib tug series ntawm electrodes cais los ntawm ib tug dielectric, thiab qhov tsis zoo voltage ntawm cov electrodes nce nyob rau hauv ib ntus los ntawm kev sib txuas series. Qhov siab dua qhov tag nrho qhov hluav taws xob, qhov ntau dua qhov ceev tau los ntawm cov ions, uas yog, ntau dua lub zog nqa. Lub zog siab tuaj yeem tso cai rau cov impurity ions raug txhaj rau hauv cov silicon wafer los ua qhov sib sib zog nqus sib sib zog nqus, thaum lub zog qis tuaj yeem siv los ua qhov sib txuas ntiav.

(5)Luam theej duab disk

Lub tsom ion beam feem ntau yog me me hauv txoj kab uas hla. Txoj kab uas hla ntawm lub nruab nrab beam tam sim no implanter yog hais txog 1 cm, thiab hais tias ntawm ib tug loj beam tam sim no implanter yog hais txog 3 cm. Tag nrho cov silicon wafer yuav tsum tau them los ntawm scanning. Qhov rov ua dua ntawm kev cog tshuaj yog txiav txim siab los ntawm kev tshuaj xyuas. Feem ntau, muaj plaub hom implanter scanning tshuab:

① electrostatic scanning;

② mechanical scanning;

③ hybrid scanning;

④ parallel scanning.

(6)Static hluav taws xob neutralization system:

Thaum lub sij hawm implantation txheej txheem, lub ion beam hits lub silicon wafer thiab ua rau tsub zuj zuj ntawm daim npog qhov ncauj. Cov txiaj ntsig tau txais txiaj ntsig hloov pauv cov nqi sib npaug hauv cov kab hluav taws xob ion, ua rau lub teeb pom kev loj dua thiab cov tshuaj faib tsis sib npaug. Nws kuj tseem tuaj yeem tawg los ntawm cov txheej txheem oxide saum npoo thiab ua rau cov cuab yeej tsis ua haujlwm. Tam sim no, silicon wafer thiab ion beam feem ntau yog muab tso rau hauv qhov chaw ruaj khov plasma ib puag ncig hu ua plasma electron da dej system, uas tuaj yeem tswj tau qhov kev them nyiaj ntawm silicon wafer. Txoj kev no rho tawm electrons los ntawm cov ntshav (feem ntau yog argon los yog xenon) nyob rau hauv ib tug arc chamber nyob rau hauv txoj kev ion beam thiab nyob ze ntawm silicon wafer. Lub plasma yog lim thiab tsuas yog cov electrons thib ob tuaj yeem ncav cuag qhov chaw ntawm silicon wafer kom tsis txhob muaj qhov zoo.

(7)txheej txheem kab noj hniav:

Kev txhaj tshuaj ntawm ion beams rau hauv silicon wafers tshwm sim hauv cov txheej txheem chamber. Cov txheej txheem chamber yog ib qho tseem ceeb ntawm lub implanter, nrog rau kev soj ntsuam qhov system, lub davhlau ya nyob twg chaw nres tsheb nrog lub tshuab nqus tsev vacuum rau kev thauj khoom thiab tshem tawm silicon wafers, silicon wafer hloov chaw, thiab lub computer tswj system. Tsis tas li ntawd, muaj qee cov khoom siv rau kev soj ntsuam cov koob tshuaj thiab tswj cov teebmeem channel. Yog tias siv tshuab scanning, qhov chaw nres tsheb davhlau ya nyob twg yuav loj heev. Lub tshuab nqus tsev ntawm cov txheej txheem chamber yog pumped mus rau hauv qab lub siab xav tau los ntawm cov txheej txheem los ntawm ib tug multi-theem mechanical twj tso kua mis, ib tug turbomolecular twj tso kua mis, thiab ib tug condensation twj tso kua mis, uas feem ntau yog hais txog 1 × 10-6Torr los yog tsawg dua.

(8)Dosage tswj system:

Kev tshuaj xyuas lub sij hawm tiag tiag hauv ib qho ion implanter yog ua tiav los ntawm kev ntsuas lub ion beam ncav cuag lub silicon wafer. Lub ion beam tam sim no yog ntsuas los ntawm lub sensor hu ua Faraday khob. Nyob rau hauv ib qho yooj yim Faraday system, muaj ib tug tam sim no sensor nyob rau hauv lub ion beam txoj kev uas ntsuas qhov tam sim no. Txawm li cas los xij, qhov no nthuav tawm qhov teeb meem, vim hais tias lub ion beam reacts nrog lub sensor thiab tsim cov electrons thib ob uas yuav ua rau kev nyeem ntawv tsis raug. Lub Faraday system tuaj yeem txwv cov khoom siv hluav taws xob thib ob uas siv hluav taws xob lossis cov hlau nplaum kom tau txais cov kab hluav taws xob tam sim no nyeem. Qhov ntsuas tam sim no los ntawm Faraday system yog pub rau hauv lub tshuab hluav taws xob siv hluav taws xob, uas ua raws li qhov tam sim no accumulator (uas tsis tu ncua khaws cov ntsuas hluav taws xob tam sim no). Tus maub los yog siv los txheeb xyuas tag nrho cov tam sim no rau lub sijhawm cog qoob loo thiab suav lub sijhawm xav tau rau ib koob tshuaj.

3.2 Kev kho puas tsuaj

Ion implantation yuav khob atoms tawm ntawm lub lattice qauv thiab ua rau cov silicon wafer lattice puas. Yog hais tias cov tshuaj implanted loj, lub implanted txheej yuav ua amorphous. Tsis tas li ntawd, cov ions implanted yeej tsis nyob hauv cov ntsiab lus lattice ntawm silicon, tab sis nyob rau hauv txoj hauj lwm lattice. Cov impurities interstitial no tsuas tuaj yeem qhib tau tom qab qhov kub thiab txias annealing txheej txheem.

Annealing tuaj yeem ua kom sov lub implanted silicon wafer los kho cov lattice defects; nws tseem tuaj yeem txav impurity atoms mus rau cov ntsiab lus lattice thiab qhib lawv. Qhov kub xav tau los kho cov kab laum qhov tsis xws luag yog li 500 ° C, thiab qhov kub yuav tsum tau ua kom cov impurity atoms yog li 950 ° C. Kev ua kom cov impurities muaj feem xyuam rau lub sij hawm thiab qhov kub thiab txias: lub sij hawm ntev thiab qhov kub thiab txias, qhov siab dua qhov impurities tau qhib. Muaj ob txoj hauv kev rau annealing silicon wafers:

① kub-kub rauv annealing;

② ceev thermal annealing (RTA).

Kub kub rauv annealing: Kub kub rauv annealing yog ib txwm annealing txoj kev, uas siv ib tug kub kub rauv kom sov lub silicon wafer rau 800-1000 ℃ thiab khaws cia rau 30 feeb. Ntawm qhov kub no, silicon atoms txav rov qab mus rau txoj hauj lwm lattice, thiab impurity atoms kuj tuaj yeem hloov cov silicon atoms thiab nkag mus rau hauv lattice. Txawm li cas los xij, kev kho cua sov ntawm qhov kub thiab lub sijhawm yuav ua rau muaj qhov tsis zoo ntawm qhov tsis huv, uas yog ib yam dab tsi uas niaj hnub IC tsim kev lag luam tsis xav pom.

Rapid Thermal Annealing: Rapid thermal annealing (RTA) kho silicon wafers nrog qhov kub thiab txias heev thiab luv luv ntawm lub hom phiaj kub (feem ntau yog 1000 ° C). Annealing ntawm implanted silicon wafers feem ntau yog ua nyob rau hauv ib tug ceev thermal processor nrog Ar los yog N2. Cov txheej txheem kub ceev ceev thiab lub sijhawm luv luv tuaj yeem ua kom zoo dua qub ntawm cov lattice defects, ua kom cov impurities thiab inhibition ntawm impurity diffusion. RTA kuj tseem tuaj yeem txo qhov kev hloov pauv hloov pauv hloov pauv thiab yog txoj hauv kev zoo tshaj plaws los tswj kev sib txuas qhov tob hauv qhov sib txuas ntiav ntiav.

———————————————————————————————————————————————————————— ————————————————

Semicera tuaj yeem muab taugraphite qhov chaw, soft/rigid xav, silicon carbide qhov chaw, CVD silicon carbide qhov chaw, thiabSiC/TaC coated qhov chawnrog hauv 30 hnub.

Yog tias koj txaus siab rau cov khoom lag luam semiconductor saum toj no,thov tsis txhob yig tiv tauj peb thawj zaug.

Tel: +86-13373889683

WhatsApp: +86-15957878134

Email: sales01@semi-cera.com

Post lub sij hawm: Aug-31-2024