1. Taw qhia

Cov txheej txheem ntawm kev txuas cov khoom (cov khoom siv raw) rau saum npoo ntawm cov ntaub ntawv substrate los ntawm cov txheej txheem ntawm lub cev lossis tshuaj hu ua nyias zaj duab xis loj hlob.

Raws li kev ua haujlwm sib txawv, kev sib xyaw ua ke ntawm cov yeeb yaj kiab nyias nyias tuaj yeem muab faib ua:

- Lub cev Vapor Deposition (PVD);

-Chemical Vapor Deposition (CVD);

-Txuas ntxiv.

2. Nyias zaj duab xis loj hlob txheej txheem

2.1 Lub cev vapor deposition thiab sputtering txheej txheem

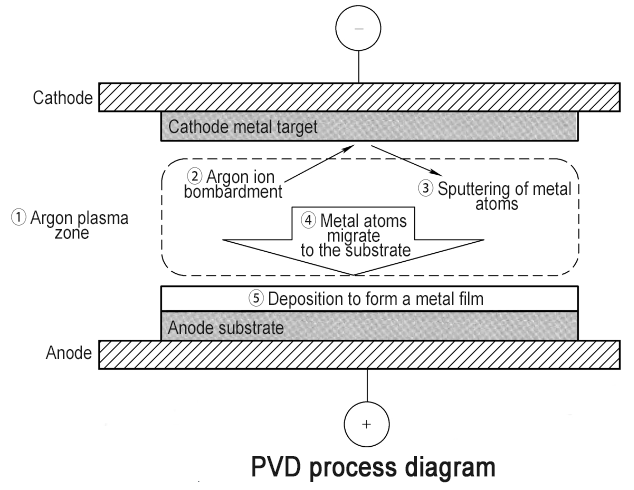

Lub cev vapor deposition (PVD) txheej txheem yog hais txog kev siv lub cev txoj kev xws li nqus evaporation, sputtering, plasma txheej thiab molecular beam epitaxy los ua ib tug nyias zaj duab xis nyob rau saum npoo ntawm wafer.

Hauv kev lag luam VLSI, PVD thev naus laus zis tau siv dav tshaj plaws yog sputtering, uas yog siv rau electrodes thiab hlau sib txuas ntawm kev sib txuas ua ke. Sputtering yog txheej txheem uas tsis tshua muaj roj [xws li argon (Ar)] ionized rau hauv ions (xws li Ar +) nyob rau hauv qhov kev txiav txim ntawm ib qho hluav taws xob sab nraud nyob rau hauv lub tshuab nqus tsev siab, thiab bombard cov khoom lub hom phiaj nyob rau hauv ib tug high voltage ib puag ncig, knocking tawm atoms los yog molecules ntawm lub hom phiaj cov ntaub ntawv, thiab ces mus txog ntawm lub nto ntawm lub wafer los ua ib tug nyias zaj duab xis tom qab ib tug kev sib tsoo-dawb ya davhlau txheej txheem. Ar muaj cov khoom siv tshuaj ruaj khov, thiab nws cov ions yuav tsis hnov mob rau cov khoom siv thiab cov yeeb yaj kiab. Raws li kev sib koom ua ke chips nkag mus rau 0.13μm tooj liab interconnect era, tooj liab barrier khoom txheej siv titanium nitride (TiN) los yog tantalum nitride (TaN) zaj duab xis. Qhov kev thov rau kev lag luam thev naus laus zis tau txhawb kev tshawb fawb thiab kev tsim cov tshuaj tiv thaiv kab mob sputtering technology, uas yog, nyob rau hauv sputtering chamber, ntxiv rau Ar, kuj muaj ib tug reactive gas nitrogen (N2), yog li ntawd lub Ti los yog Ta bombarded los ntawm lub phiaj cov khoom Ti los yog Ta reacts nrog N2 los tsim cov TiN los yog TaN zaj duab xis xav tau.

Muaj peb txoj kev siv sputtering, uas yog DC sputtering, RF sputtering thiab magnetron sputtering. Raws li kev sib koom ua ke ntawm kev sib xyaw ua ke txuas ntxiv mus ntxiv, cov txheej txheem ntawm ntau txheej hlau thaiv yog nce, thiab kev siv PVD thev naus laus zis tau dhau los ua ntau dua. PVD cov ntaub ntawv muaj xws li Al-Si, Al-Cu, Al-Si-Cu, Ti, Ta, Co, TiN, TaN, Ni, WSi2, thiab lwm yam.

PVD thiab sputtering txheej txheem feem ntau yog ua tiav nyob rau hauv ib tug heev kaw cov tshuaj tiv thaiv chamber nrog ib tug nqus tsev kawm ntawv ntawm 1 × 10-7 mus rau 9 × 10-9 Torr, uas yuav xyuas kom meej lub purity ntawm cov roj thaum lub sij hawm cov tshuaj tiv thaiv; Nyob rau tib lub sijhawm, ib qho hluav taws xob sab nraud yuav tsum tau ionize cov pa roj tsawg los tsim kom muaj qhov hluav taws xob txaus txaus los tua lub hom phiaj. Lub ntsiab tsis zoo rau kev ntsuam xyuas PVD thiab sputtering txheej txheem muaj xws li cov hmoov av, nrog rau cov nqi kuj, uniformity, reflectivity thickness thiab kev ntxhov siab ntawm cov zaj duab xis tsim.

2.2 Tshuaj Vapor Deposition thiab Sputtering txheej txheem

Chemical vapor deposition (CVD) yog hais txog cov txheej txheem thev naus laus zis uas muaj ntau yam gaseous reactants nrog cov kev sib txawv ib feem ntawm cov kev sib txawv ntawm cov kev sib txawv ntawm qhov kub thiab txias, thiab cov khoom tsim tawm tau muab tso rau saum npoo ntawm cov khoom siv substrate kom tau txais qhov xav tau nyias. zaj duab xis. Hauv cov txheej txheem tsim hluav taws xob sib xyaw ua ke, cov khoom siv zaj duab xis tau txais feem ntau yog cov khoom sib txuas xws li oxides, nitrides, carbides, lossis cov ntaub ntawv xws li polycrystalline silicon thiab amorphous silicon. Selective epitaxial kev loj hlob, uas yog feem ntau siv tom qab 45nm node, xws li qhov chaw thiab ntws SiGe los yog Si selective epitaxial loj hlob, kuj yog ib tug CVD technology.

Cov thev naus laus zis no tuaj yeem txuas ntxiv tsim cov ntaub ntawv siv lead ua ib yam ntawm tib hom lossis zoo ib yam li cov thawj lattice ntawm ib qho siv lead ua substrate ntawm silicon los yog lwm yam ntaub ntawv raws li thawj lattice. CVD yog dav siv nyob rau hauv kev loj hlob ntawm insulating dielectric films (xws li SiO2, Si3N4 thiab SiON, thiab lwm yam) thiab hlau films (xws li tungsten, thiab lwm yam).

Feem ntau, raws li kev faib tawm siab, CVD tuaj yeem muab faib ua atmospheric pressure chemical vapor deposition (APCVD), sub-atmosphere pressure chemical vapor deposition (SAPCVD) and low pressure chemical vapor deposition (LPCVD).

Raws li qhov ntsuas kub, CVD tuaj yeem muab faib ua qhov kub thiab txias / qis kub oxide zaj duab xis tshuaj vapor deposition (HTO / LTO CVD) thiab ceev thermal chemical vapor deposition (Rapid Thermal CVD, RTCVD);

Raws li cov tshuaj tiv thaiv, CVD tuaj yeem muab faib ua silane-based CVD, polyester-based CVD (TEOS-based CVD) thiab hlau organic chemical vapor deposition (MOCVD);

Raws li kev faib hluav taws xob, CVD tuaj yeem muab faib ua cov thermal chemical vapor deposition (Thermal CVD), plasma enhanced chemical vapor deposition (Plasma Enhanced CVD, PECVD) thiab high density plasma chemical vapor deposition (High Density Plasma CVD, HDPCVD). Tsis ntev los no, flowable chemical vapor deposition (Flowable CVD, FCVD) nrog rau qhov sib txawv zoo filling muaj peev xwm kuj tau tsim.

Cov yeeb yaj kiab CVD sib txawv muaj cov khoom sib txawv (xws li tshuaj lom neeg muaj pes tsawg leeg, dielectric tsis tu ncua, nro, kev ntxhov siab thiab tawg hluav taws xob) thiab tuaj yeem siv cais raws li cov txheej txheem sib txawv (xws li kub, qib kev pab them nqi, kev ua kom tiav, thiab lwm yam).

2.3 Atomic txheej deposition txheej txheem

Atomic layer deposition (ALD) yog hais txog lub deposition ntawm atoms txheej los ntawm txheej ntawm ib tug substrate khoom los ntawm loj hlob ib tug atomic zaj duab xis txheej los ntawm txheej. Ib tug raug ALD txais yuav cov txheej txheem ntawm input gaseous precursors rau hauv lub reactor nyob rau hauv ib tug alternating pulsed yam.

Piv txwv li, ua ntej, cov tshuaj tiv thaiv precursor 1 yog nkag mus rau hauv lub substrate nto, thiab tom qab cov tshuaj adsorption, ib tug atomic txheej yog tsim nyob rau hauv lub substrate nto; tom qab ntawd lub precursor 1 seem nyob rau hauv lub substrate nto thiab nyob rau hauv cov tshuaj tiv thaiv chamber yog pumped tawm los ntawm lub twj tso kua mis cua; Tom qab ntawd cov tshuaj tiv thaiv precursor 2 yog nkag mus rau hauv lub substrate nto, thiab chemically reacts nrog precursor 1 adsorbed ntawm lub substrate nto los tsim cov ntaub ntawv nyias nyias thiab cov khoom los ntawm lub substrate nto; thaum lub precursor 1 reacts kiag li, cov tshuaj tiv thaiv yuav cia li txiav, uas yog tus kheej-limiting yam ntxwv ntawm ALD, thiab ces cov seem reactants thiab by-products raug rho tawm los npaj rau theem tom ntej ntawm kev loj hlob; los ntawm kev rov ua cov txheej txheem saum toj no tsis tu ncua, qhov tso tawm ntawm cov ntaub ntawv nyias zaj duab xis loj hlob los ntawm txheej nrog ib qho atoms tuaj yeem ua tiav.

Ob leeg ALD thiab CVD yog txoj hauv kev los qhia txog cov tshuaj tiv thaiv gaseous los teb cov tshuaj lom neeg ntawm cov substrate nto, tab sis qhov txawv yog tias cov tshuaj tiv thaiv gaseous ntawm CVD tsis muaj cov yam ntxwv ntawm kev loj hlob ntawm tus kheej. Nws tuaj yeem pom tau tias tus yuam sij rau kev txhim kho ALD thev naus laus zis yog nrhiav cov neeg ua ntej nrog kev txwv tus kheej cov tshuaj tiv thaiv.

2.4 Epitaxial txheej txheem

Epitaxial txheej txheem yog hais txog cov txheej txheem ntawm kev loj hlob ib qho kev txiav txim tag nrho ib txheej siv lead ua rau ntawm lub substrate. Feem ntau hais lus, cov txheej txheem epitaxial yog kom loj hlob ib txheej siv lead ua nrog tib lub lattice orientation raws li tus thawj substrate ntawm ib tug siv lead ua substrate. Epitaxial txheej txheem yog dav siv nyob rau hauv semiconductor manufacturing, xws li epitaxial silicon wafers nyob rau hauv lub integrated circuit kev lag luam, embedded qhov chaw thiab ntws epitaxial loj hlob ntawm MOS transistors, epitaxial loj hlob ntawm LED substrates, thiab lwm yam.

Raws li lub xeev sib txawv ntawm qhov kev loj hlob, txoj kev loj hlob epitaxial tuaj yeem muab faib ua cov theem epitaxy, kua theem epitaxy, thiab vapor theem epitaxy. Hauv kev tsim hluav taws xob sib xyaw ua ke, feem ntau siv cov txheej txheem epitaxial yog cov khoom theem epitaxy thiab vapor theem epitaxy.

Khoom theem epitaxy: hais txog kev loj hlob ntawm ib txheej siv lead ua ntawm ib lub substrate siv cov khoom siv. Piv txwv li, thermal annealing tom qab ion implantation yog qhov ua tau zoo ntawm cov txheej txheem epitaxy. Thaum lub sij hawm ion implantation, silicon atoms ntawm silicon wafer yog bombarded los ntawm high-zog implanted ions, tawm hauv lawv cov thawj lattice txoj hauj lwm thiab ua amorphous, tsim amorphous silicon txheej. Tom qab qhov kub thiab txias thermal annealing, cov amorphous atoms rov qab mus rau lawv txoj haujlwm lattice thiab nyob twj ywm raws li atomic crystal orientation hauv substrate.

Txoj kev loj hlob ntawm vapor theem epitaxy muaj xws li tshuaj vapor theem epitaxy, molecular beam epitaxy, atomic txheej epitaxy, thiab lwm yam. Nyob rau hauv integrated circuit manufacturing, tshuaj vapor theem epitaxy yog feem ntau siv. Lub hauv paus ntsiab lus ntawm cov tshuaj vapor theem epitaxy yog qhov pib zoo ib yam li cov tshuaj vapor deposition. Ob qho tib si yog cov txheej txheem uas tso cov yeeb yaj kiab nyias los ntawm kev siv tshuaj lom neeg ntawm cov wafers tom qab sib xyaw roj.

Qhov txawv yog vim hais tias cov tshuaj vapor theem epitaxy loj hlob ib leeg siv lead ua txheej, nws muaj ntau dua qhov yuav tsum tau rau cov impurity cov ntsiab lus nyob rau hauv cov khoom thiab kev huv si ntawm wafer nto. Cov txheej txheem tshuaj vapor thaum ntxov epitaxial silicon yuav tsum tau ua nyob rau hauv qhov kub thiab txias (ntau dua 1000 ° C). Nrog rau kev txhim kho cov txheej txheem cov cuab yeej, tshwj xeeb tshaj yog kev siv tshuab nqus tsev vacuum txauv chamber, kev huv huv ntawm cov khoom siv kab noj hniav thiab qhov chaw ntawm silicon wafer tau zoo heev, thiab silicon epitaxy tuaj yeem nqa tawm ntawm qhov kub thiab txias (600-700 ° C). C). Cov txheej txheem epitaxial silicon wafer yog kom loj hlob ib txheej ntawm ib leeg siv lead ua silicon rau ntawm qhov chaw ntawm silicon wafer.

Piv nrog rau cov thawj silicon substrate, cov epitaxial silicon txheej muaj ntau dua purity thiab tsawg dua lattice defects, yog li txhim kho cov tawm los ntawm semiconductor manufacturing. Tsis tas li ntawd, qhov kev loj hlob tuab thiab doping concentration ntawm epitaxial silicon txheej loj hlob ntawm silicon wafer tuaj yeem tsim tau yooj yim, uas coj tau yooj yim rau kev tsim cov cuab yeej, xws li txo cov substrate kuj thiab txhim kho substrate cais. Cov txheej txheem embedded qhov-drain epitaxial txheej txheem yog ib tug technology dav siv nyob rau hauv advanced logic technology nodes.

Nws hais txog cov txheej txheem ntawm epitaxially loj hlob doped germanium silicon los yog silicon nyob rau hauv qhov chaw thiab ntws cheeb tsam ntawm MOS transistors. Cov txiaj ntsig tseem ceeb ntawm kev qhia txog cov txheej txheem embedded-drain epitaxial muaj xws li: kev loj hlob ntawm pseudocrystalline txheej uas muaj kev ntxhov siab vim kev hloov pauv ntawm lattice, txhim kho channel cab kuj; nyob rau hauv-situ doping ntawm qhov chaw thiab ntws yuav txo tau cov cab kuj ntawm qhov chaw-drain hlws ris thiab txo qhov tsis xws luag ntawm high-zog ion implantation.

3. nyias zaj duab xis loj hlob khoom

3.1 Cov khoom siv nqus tsev vacuum

Nqus evaporation yog txheej txheej txheej uas ua kom sov cov khoom hauv lub tshuab nqus tsev kom ua rau lawv evaporate, vaporize lossis sublimate, thiab tom qab ntawd condense thiab tso rau ntawm qhov chaw ntawm cov khoom siv substrate ntawm qhov kub thiab txias.

Feem ntau nws muaj peb ntu, uas yog lub tshuab nqus tsev, evaporation system thiab cua sov system. Lub tshuab nqus tsev muaj lub tshuab nqus tsev thiab lub tshuab nqus tsev twj, thiab nws lub luag haujlwm tseem ceeb yog muab lub tshuab nqus tsev tsim nyog rau evaporation. Cov txheej txheem evaporation muaj ib lub rooj evaporation, cov khoom siv cua sov thiab ntsuas qhov ntsuas kub.

Lub hom phiaj cov khoom yuav tsum tau evaporated (xws li Ag, Al, thiab lwm yam) muab tso rau ntawm lub rooj evaporation; Cov cua kub thiab ntsuas kub ntsuas qhov ntsuas yog qhov kaw-voj siv los tswj cov evaporation kub kom ntseeg tau tias cov evaporation du. Lub tshuab cua sov muaj cov theem wafer thiab cov khoom siv cua sov. Lub wafer theem yog siv los tso lub substrate uas nyias zaj duab xis yuav tsum tau evaporated, thiab cov cua sov tivthaiv yog siv los paub substrate cua sov thiab ntsuas kub ntsuas kev tswj xyuas.

Lub tshuab nqus tsev ib puag ncig yog ib qho tseem ceeb heev nyob rau hauv lub tshuab nqus tsev evaporation txheej txheem, uas muaj feem xyuam rau tus nqi evaporation thiab qhov zoo ntawm cov zaj duab xis. Yog tias lub tshuab nqus tsev kawm tsis tau raws li qhov yuav tsum tau ua, cov vaporized atoms lossis molecules yuav sib tsoo ntau zaus nrog cov roj seem ntawm cov roj molecules, ua rau lawv txoj kev dawb me me, thiab cov atoms lossis molecules yuav tawg heev, yog li hloov cov kev taw qhia ntawm kev txav thiab txo cov yeeb yaj kiab. tsim tus nqi.

Tsis tas li ntawd, vim muaj cov seem ntawm cov roj impurity roj molecules, cov yeeb yaj kiab tso tawm yog cov kab mob loj thiab tsis zoo, tshwj xeeb tshaj yog thaum lub siab nce siab ntawm lub chamber tsis tau raws li tus qauv thiab muaj cov pa tawm, cua yuav xau mus rau hauv lub tshuab nqus tsev chamber. , uas yuav muaj kev cuam tshuam loj rau cov yeeb yaj kiab zoo.

Cov yam ntxwv ntawm cov khoom siv nqus tsev vacuum evaporation txiav txim siab tias qhov sib xws ntawm txheej txheej ntawm cov substrates loj yog qhov tsis zoo. Txhawm rau txhim kho nws qhov sib xws, txoj kev nce qhov chaw-substrate nrug thiab tig lub substrate feem ntau yog saws, tab sis nce qhov chaw-substrate nrug yuav txi qhov kev loj hlob thiab purity ntawm zaj duab xis. Nyob rau tib lub sijhawm, vim qhov nce hauv qhov chaw nqus tsev, qhov kev siv ntawm cov khoom evaporated yog txo.

3.2 DC lub cev vapor deposition khoom

Direct tam sim no lub cev vapor deposition (DCPVD) tseem hu ua cathode sputtering los yog nqus DC ob-theem sputtering. Lub hom phiaj ntawm lub tshuab nqus tsev DC sputtering yog siv los ua cathode thiab cov substrate yog siv los ua anode. Vacuum sputtering yog tsim cov ntshav los ntawm ionizing cov txheej txheem roj.

Cov khoom siv hluav taws xob hauv cov ntshav tau nrawm nrawm hauv qhov hluav taws xob kom tau txais qee lub zog. Cov khoom uas muaj lub zog txaus foob rau saum npoo ntawm cov khoom siv, kom lub hom phiaj atoms sputtered tawm; cov sputtered atoms nrog ib tug tej yam kinetic zog txav mus rau lub substrate los ua ib tug nyias zaj duab xis nyob rau saum npoo ntawm lub substrate. Cov roj siv rau sputtering feem ntau yog cov pa roj tsawg, xws li argon (Ar), yog li cov yeeb yaj kiab tsim los ntawm sputtering yuav tsis muaj kab mob; Tsis tas li ntawd, lub atomic radius ntawm argon yog tsim nyog rau sputtering.

Qhov loj ntawm sputtering hais yuav tsum nyob ze rau qhov loj ntawm lub hom phiaj atoms yuav tsum sputtered. Yog hais tias cov khoom loj dhau los yog me me dhau lawm, cov khoom siv hluav taws xob tsis tuaj yeem tsim tau. Ntxiv nrog rau qhov loj ntawm lub atom, qhov loj ntawm lub atom tseem yuav cuam tshuam rau qhov zoo ntawm sputtering. Yog hais tias lub sputtering particle qhov chaw yog lub teeb dhau, lub hom phiaj atoms yuav tsis raug sputtered; Yog hais tias cov sputtering hais hnyav dhau lawm, lub hom phiaj yuav "khoov" thiab lub hom phiaj yuav tsis raug sputtered.

Cov khoom siv hom phiaj siv hauv DCPVD yuav tsum yog tus neeg xyuas pib. Qhov no yog vim hais tias thaum lub argon ions nyob rau hauv cov txheej txheem roj bombard lub hom phiaj cov khoom, lawv yuav recombine nrog cov electrons nyob rau saum npoo ntawm lub hom phiaj cov khoom. Thaum cov khoom siv lub hom phiaj yog tus neeg xyuas pib xws li cov hlau, cov khoom siv hluav taws xob tau siv los ntawm qhov kev sib txuas ua ke no yooj yim dua los ntawm cov khoom siv hluav taws xob thiab cov hluav taws xob dawb hauv lwm qhov ntawm cov khoom siv los ntawm cov khoom siv hluav taws xob, kom lub ntsej muag ntawm lub hom phiaj cov khoom siv los ntawm cov khoom siv hluav taws xob. tag nrho tseem tsis zoo them thiab sputtering yog khaws cia.

Ntawm qhov tsis sib xws, yog tias cov khoom siv lub hom phiaj yog ib qho insulator, tom qab cov khoom siv hluav taws xob nyob rau saum npoo ntawm cov khoom siv tau rov ua dua, cov hluav taws xob dawb hauv lwm qhov ntawm cov khoom siv lub hom phiaj tsis tuaj yeem rov ua dua los ntawm hluav taws xob conduction, thiab txawm tias cov nqi zoo yuav sib sau rau ntawm qhov chaw. nto ntawm lub hom phiaj cov khoom, ua rau lub hom phiaj cov khoom muaj peev xwm sawv, thiab qhov tsis zoo nqi ntawm lub hom phiaj cov khoom yog tsis muaj zog kom txog rau thaum nws ploj mus, nws thiaj li ua rau qhov kev txiav ntawm sputtering.

Yog li ntawd, txhawm rau ua kom cov ntaub ntawv insulating kuj siv tau rau sputtering, nws yog ib qho tsim nyog yuav tsum nrhiav lwm txoj kev sputtering. Xov tooj cua zaus sputtering yog ib txoj kev sputtering uas haum rau ob qho tib si conductive thiab non-conductive lub hom phiaj.

Lwm qhov tsis zoo ntawm DCPVD yog qhov hluav taws xob hluav taws xob siab thiab cov hluav taws xob tawg ntawm lub substrate muaj zog. Ib txoj hauv kev zoo los daws qhov teeb meem no yog siv magnetron sputtering, yog li magnetron sputtering yog qhov muaj txiaj ntsig tiag tiag hauv kev sib koom ua ke.

3.3 RF Lub Cev Vapor Deposition Khoom

Xov tooj cua zaus lub cev vapor deposition (RFPVD) siv xov tooj cua zaus lub zog raws li qhov excitation qhov chaw thiab yog PVD txoj kev haum rau ntau yam hlau thiab cov ntaub ntawv uas tsis yog hlau.

Qhov ntau zaus ntawm RF fais fab mov siv hauv RFPVD yog 13.56MHz, 20MHz, thiab 60MHz. Qhov zoo thiab qhov tsis zoo ntawm RF fais fab mov tshwm sim ua ke. Thaum lub hom phiaj PVD nyob rau hauv qhov zoo ib nrab voj voog, vim hais tias lub hom phiaj nto yog nyob rau hauv ib tug zoo muaj peev xwm, cov electrons nyob rau hauv cov txheej txheem cua yuav ntws mus rau lub hom phiaj nto mus rau neutralize tus nqi zoo accumulated nyob rau hauv nws nto, thiab txawm mus txuas ntxiv electrons, ua rau nws nto tsis zoo biased; Thaum lub hom phiaj sputtering nyob rau hauv qhov tsis zoo ib nrab voj voog, qhov zoo ions yuav txav mus rau lub hom phiaj thiab yuav ua rau ib nrab neutralized ntawm lub hom phiaj nto.

Qhov tseem ceeb tshaj plaws yog qhov kev txav ceev ntawm cov hluav taws xob hauv RF hluav taws xob yog nrawm dua li qhov zoo ions, thaum lub sij hawm ntawm qhov zoo thiab qhov tsis zoo ib nrab voj voog yog tib yam, yog li tom qab ua tiav lub voj voog, lub hom phiaj saum npoo yuav yog. "net" tsis zoo them nqi. Yog li ntawd, nyob rau hauv thawj ob peb lub voj voog, tus nqi tsis zoo ntawm lub hom phiaj saum npoo qhia tau tias muaj kev nce ntxiv; tom qab ntawd, lub hom phiaj nto mus txog qhov muaj peev xwm tsis zoo; Tom qab ntawd, vim hais tias tus nqi tsis zoo ntawm lub hom phiaj muaj kev cuam tshuam rau electrons, tus nqi ntawm qhov zoo thiab qhov tsis zoo tau txais los ntawm lub hom phiaj electrode nyhav sib npaug, thiab lub hom phiaj nthuav tawm cov nqi tsis zoo.

Los ntawm cov txheej txheem saum toj no, nws tuaj yeem pom tias cov txheej txheem ntawm kev tsim hluav taws xob tsis zoo tsis muaj dab tsi ua nrog cov khoom ntawm cov khoom siv nws tus kheej, yog li RFPVD txoj kev tuaj yeem tsis tsuas yog daws qhov teeb meem ntawm sputtering ntawm insulating lub hom phiaj, tab sis kuj zoo sib xws. nrog cov pa hlau conductor lub hom phiaj.

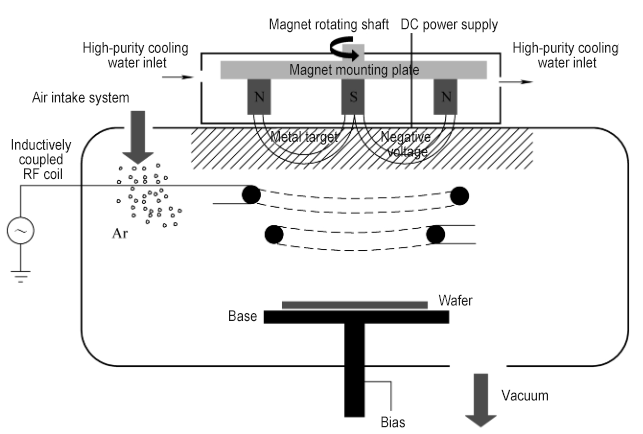

3.4 Magnetron sputtering khoom

Magnetron sputtering yog PVD txoj kev uas ntxiv cov hlau nplaum rau tom qab ntawm lub hom phiaj. Cov hlau nplaum ntxiv thiab DC fais fab mov (los yog AC fais fab mov) system tsim ib qhov chaw magnetron sputtering. Lub sputtering qhov chaw yog siv los tsim ib qho kev sib tham sib electromagnetic teb nyob rau hauv lub chamber, ntes thiab txwv kev txav ntau ntawm electrons nyob rau hauv lub plasma nyob rau hauv lub chamber, ncua txoj kev txav ntawm electrons, thiab yog li nce lub concentration ntawm cov ntshav, thiab thaum kawg ua tiav ntau. tso nyiaj.

Tsis tas li ntawd, vim hais tias ntau electrons raug khi ze ntawm qhov chaw ntawm lub hom phiaj, lub foob pob ntawm lub substrate los ntawm electrons raug txo, thiab qhov kub ntawm lub substrate yog txo. Piv nrog rau lub tiaj-phaj DCPVD thev naus laus zis, ib qho ntawm cov cuab yeej pom tseeb tshaj plaws ntawm magnetron lub cev vapor deposition tshuab yog tias qhov hluav taws xob tawm hluav taws xob qis dua thiab ruaj khov dua.

Vim nws cov plasma concentration siab dua thiab loj dua sputtering tawm los, nws muaj peev xwm ua tau zoo heev deposition efficiency, deposition thickness tswj nyob rau hauv ib tug loj loj ntau yam, meej muaj pes tsawg leeg tswj thiab qis ignition voltage. Yog li ntawd, magnetron sputtering yog nyob rau hauv ib tug tseem ceeb txoj hauj lwm nyob rau hauv tam sim no hlau zaj duab xis PVD. Qhov yooj yim tshaj plaws magnetron sputtering qhov tsim yog muab ib pawg hlau nplaum nyob rau sab nraum qab ntawm lub hom phiaj tiaj tus (sab nraum lub tshuab nqus tsev) los tsim kom muaj cov hlau nplaum sib npaug rau lub hom phiaj hauv cheeb tsam hauv cheeb tsam ntawm lub hom phiaj.

Yog tias muab cov hlau nplaum ruaj khov, nws qhov chaw sib nqus yog qhov ruaj khov, uas ua rau muaj qhov sib nqus ruaj khov sib nqus ntawm lub hom phiaj ntawm lub chamber. Tsuas yog cov ntaub ntawv nyob rau hauv tej cheeb tsam ntawm lub hom phiaj yog sputtered, lub hom phiaj kev siv tus nqi yog tsawg, thiab cov uniformity ntawm lub npaj zaj duab xis yog tsis zoo.

Muaj qee qhov tshwm sim uas cov hlau sputtered lossis lwm yam khoom siv yuav raug tso rov qab rau ntawm lub hom phiaj nto, yog li sib sau ua ke rau hauv cov khoom thiab ua rau muaj qhov tsis xws luag. Yog li ntawd, kev lag luam magnetron sputtering qhov chaw feem ntau siv cov hlau nplaum tig los txhim kho cov yeeb yaj kiab sib xws, lub hom phiaj siv tus nqi, thiab tag nrho lub hom phiaj sputtering.

Nws yog ib qho tseem ceeb kom sib npaug ntawm peb yam. Yog tias qhov sib npaug tsis zoo, nws yuav ua rau cov yeeb yaj kiab zoo sib xws thaum txo qhov kev siv lub hom phiaj (ua kom lub neej luv), lossis ua tsis tiav tag nrho lub hom phiaj sputtering lossis tag nrho lub hom phiaj corrosion, uas yuav ua rau muaj teeb meem particle thaum lub sij hawm sputtering. txheej txheem.

Hauv magnetron PVD thev naus laus zis, nws yog ib qho tsim nyog yuav tsum xav txog kev hloov cov hlau nplaum sib nqus, lub hom phiaj zoo, lub hom phiaj cua txias thiab magnetron sputtering qhov chaw, nrog rau kev ua haujlwm ntawm lub hauv paus uas nqa lub wafer, xws li wafer adsorption thiab kub tswj. Nyob rau hauv cov txheej txheem PVD, qhov kub ntawm lub wafer yog tswj kom tau txais cov qauv siv lead ua uas yuav tsum tau muaj, cov nplej loj thiab kev taw qhia, nrog rau kev ruaj ntseg ntawm kev ua haujlwm.

Txij li thaum lub tshav kub conduction ntawm sab nraum qab ntawm lub wafer thiab saum npoo ntawm lub hauv paus yuav tsum tau ib tug tej yam siab, feem ntau yog nyob rau hauv qhov kev txiav txim ntawm ob peb Torr, thiab lub siab ua hauj lwm ntawm lub chamber feem ntau yog nyob rau hauv qhov kev txiav txim ntawm ob peb mTorr, lub siab nyob rau tom qab. ntawm lub wafer yog ntau dua qhov siab ntawm qhov saum npoo ntawm lub wafer, yog li yuav tsum muaj lub tshuab chuck lossis electrostatic chuck rau txoj haujlwm thiab txwv lub wafer.

Lub tshuab chuck vam khom ntawm nws tus kheej qhov hnyav thiab ntug ntawm wafer kom ua tiav qhov haujlwm no. Txawm hais tias nws muaj qhov zoo ntawm cov qauv yooj yim thiab insensitivity rau cov khoom ntawm wafer, lub ntug nyhuv ntawm wafer yog pom tseeb, uas yog tsis conducive rau nruj tswj hais. Yog li ntawd, nws tau maj mam hloov los ntawm electrostatic chuck nyob rau hauv cov txheej txheem tsim IC.

Rau cov txheej txheem uas tsis yog qhov tshwj xeeb rau qhov kub thiab txias, tsis yog adsorption, uas tsis yog-ntug hu rau shelving txoj kev (tsis muaj qhov sib txawv ntawm qhov kub thiab txias ntawm lub wafer) kuj tseem siv tau. Thaum lub sij hawm PVD txheej txheem, lub chamber hauv ob sab phlu thiab nto ntawm qhov chaw nyob rau hauv kev sib cuag nrog cov ntshav plasma yuav muab tso thiab them. Thaum cov yeeb yaj kiab tso tawm ntau tshaj qhov txwv, cov yeeb yaj kiab yuav tawg thiab tev tawm, ua rau muaj teeb meem particle.

Yog li ntawd, kev kho saum npoo ntawm qhov chaw xws li hauv ob sab phlu yog tus yuam sij rau kev ncua qhov kev txwv no. Surface sandblasting thiab aluminium spraying yog ob txoj kev siv ntau, lub hom phiaj yog txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhim kho kev sib raug zoo ntawm zaj duab xis thiab hauv ob sab phlu.

3.5 Ionization Lub cev Vapor Deposition Khoom

Nrog rau kev txhim kho txuas ntxiv ntawm microelectronics thev naus laus zis, qhov tshwj xeeb qhov loj me tau dhau los ua me thiab me. Txij li thaum PVD thev naus laus zis tsis tuaj yeem tswj hwm qhov kev xa tawm ntawm cov khoom, lub peev xwm ntawm PVD nkag mus rau hauv qhov thiab cov kab nqaim uas muaj qhov sib piv siab yog txwv, ua rau kev nthuav dav ntawm cov khoom siv PVD ib txwm muaj kev sib tw. Nyob rau hauv cov txheej txheem PVD, raws li qhov sib piv ntawm qhov pore groove nce, qhov kev pab them nqi hauv qab txo qis, tsim cov eaves zoo li overhanging qauv ntawm lub ces kaum sab saum toj, thiab tsim cov kev pab cuam tsis muaj zog tshaj plaws ntawm lub kaum sab xis.

Ionized lub cev vapor deposition tshuab tau tsim los daws qhov teeb meem no. Nws thawj zaug plasmatizes cov hlau atoms sputtered los ntawm lub hom phiaj nyob rau hauv ntau txoj kev, thiab tom qab ntawd kho lub bias voltage loaded ntawm lub wafer tswj cov kev taw qhia thiab lub zog ntawm cov hlau ions kom tau ib tug ruaj khov directional hlau ion ntws los npaj ib tug nyias zaj duab xis, yog li txhim kho. qhov kev pab cuam ntawm lub hauv qab ntawm cov kauj ruam ntawm siab nam piv los ntawm lub qhov thiab nqaim raws.

Qhov tshwj xeeb ntawm ionized hlau plasma tshuab yog qhov sib ntxiv ntawm lub xov tooj cua zaus coil hauv chamber. Thaum lub sij hawm tus txheej txheem, lub siab ua hauj lwm ntawm lub chamber yog tswj nyob rau hauv ib tug kuj siab lub xeev (5 mus rau 10 lub sij hawm ib txwm ua hauj lwm siab). Thaum lub sij hawm PVD, lub xov tooj cua zaus coil yog siv los tsim lub thib ob plasma cheeb tsam, nyob rau hauv uas lub argon plasma concentration nce nrog lub zog ntawm xov tooj cua zaus thiab roj siab. Thaum cov hlau atoms sputtered los ntawm lub hom phiaj dhau los ntawm cheeb tsam no, lawv cuam tshuam nrog high-density argon plasma los ua hlau ions.

Kev siv RF qhov chaw ntawm lub wafer cab kuj (xws li electrostatic chuck) tuaj yeem ua rau muaj qhov tsis zoo ntawm lub wafer kom nyiam cov hlau zoo ions mus rau hauv qab ntawm qhov pore groove. Qhov kev taw qhia hlau ion ntws perpendicular mus rau qhov chaw wafer txhim kho cov kauj ruam hauv qab kev pab cuam ntawm qhov sib piv siab pores thiab nqaim raws.

Cov kev tsis zoo tsis zoo siv rau lub wafer kuj ua rau ions ua rau lub ntsej muag wafer (rov qab sputtering), uas ua rau lub cev tsis muaj zog ntawm lub qhov ncauj qhov ncauj thiab sputters cov zaj duab xis tso rau hauv qab mus rau sab phab ntsa ntawm cov ces kaum ntawm lub qhov pore hauv qab. zawj, yog li txhim kho cov kauj ruam npog ntawm cov ces kaum.

3.6 Atmospheric Pressure Chemical Vapor Deposition Equipment

Atmospheric pressure chemical vapor deposition (APCVD) cov cuab yeej hais txog cov cuab yeej uas txau cov tshuaj tiv thaiv gaseous ntawm qhov ceev mus tas li mus rau saum npoo ntawm cov khoom cua sov hauv qab ib puag ncig nrog lub siab ze ntawm atmospheric siab, ua rau cov tshuaj tiv thaiv rau cov tshuaj lom neeg. lub substrate nto, thiab cov tshuaj tiv thaiv cov khoom yog tso rau ntawm lub substrate nto los ua ib tug nyias zaj duab xis.

APCVD cov cuab yeej yog cov khoom siv CVD ntxov tshaj plaws thiab tseem siv dav hauv kev tsim khoom thiab kev tshawb fawb tshawb fawb. APCVD cov cuab yeej siv tau los npaj cov yeeb yaj kiab nyias xws li ib leeg siv lead ua silicon, polycrystalline silicon, silicon dioxide, zinc oxide, titanium dioxide, phosphosilicate iav, thiab borophosphosilicate iav.

3.7 Cov Khoom Siv Hluav Taws Xob Hluav Taws Xob Hluav Taws Xob

Low-pressure chemical vapor deposition (LPCVD) cov cuab yeej yog hais txog cov khoom siv uas siv cov khoom siv roj ntsha los ua cov tshuaj lom neeg ntawm cov khoom siv hauv qab ntawm qhov cua sov (350-1100 ° C) thiab tsis tshua muaj siab (10-100mTorr) ib puag ncig, thiab cov reactants tau tso rau ntawm qhov chaw substrate los ua ib zaj duab xis nyias. LPCVD cov cuab yeej yog tsim los ntawm APCVD los txhim kho qhov zoo ntawm cov yeeb yaj kiab nyias, txhim kho qhov sib luag ntawm cov yam ntxwv tsis xws li zaj duab xis tuab thiab tiv taus, thiab txhim kho kev tsim khoom.

Nws lub ntsiab feature yog hais tias nyob rau hauv ib tug tsawg-pressure thermal teb ib puag ncig, cov txheej txheem roj reacts chemically ntawm lub wafer substrate, thiab cov tshuaj tiv thaiv cov khoom tso rau ntawm lub substrate nto los ua ib tug nyias zaj duab xis. LPCVD cov cuab yeej muaj qhov zoo hauv kev npaj cov yeeb yaj kiab zoo thiab tuaj yeem siv los npaj cov yeeb yaj kiab nyias xws li silicon oxide, silicon nitride, polysilicon, silicon carbide, gallium nitride thiab graphene.

Piv nrog rau APCVD, qhov qis-siab cov tshuaj tiv thaiv ib puag ncig ntawm LPCVD cov cuab yeej ua rau kom txoj kev tsis pub dawb thiab diffusion coefficient ntawm cov roj hauv cov tshuaj tiv thaiv chamber.

Cov tshuaj tiv thaiv roj thiab cov cab kuj roj molecules nyob rau hauv cov tshuaj tiv thaiv chamber yuav muab sib npaug zos nyob rau hauv ib tug luv luv lub sij hawm, yog li zoo heev txhim kho lub uniformity ntawm zaj duab xis thickness, resistivity uniformity thiab kauj ruam kev pab them nqi ntawm cov zaj duab xis, thiab noj cov tshuaj tiv thaiv roj kuj yog me me. Tsis tas li ntawd, qhov chaw tsis tshua muaj siab kuj tseem ua rau kev sib kis ceev ntawm cov khoom siv roj. Cov impurities thiab cov tshuaj tiv thaiv los ntawm cov khoom lag luam tawm los ntawm cov substrate tuaj yeem raug tshem tawm sai sai ntawm thaj chaw cov tshuaj tiv thaiv los ntawm cov ciam teb txheej, thiab cov pa tshuaj tiv thaiv sai dhau los ntawm cov txheej txheem ciam teb kom ncav cuag lub substrate nto rau cov tshuaj tiv thaiv, yog li muaj txiaj ntsig zoo tiv thaiv tus kheej-doping, npaj. cov yeeb yaj kiab zoo nrog cov kev hloov pauv hauv cov cheeb tsam, thiab tseem txhim kho kev tsim khoom.

3.8 Plasma Enhanced Chemical Vapor Deposition Equipment

Plasma enhanced chemical vapor deposition (PECVD) yog ib qho kev siv thin zaj duab xis deposition technology. Thaum lub sij hawm plasma txheej txheem, lub gaseous precursor yog ionized nyob rau hauv qhov kev txiav txim ntawm plasma los tsim ib tug zoo siab active pab pawg neeg, uas diffuse mus rau lub substrate nto thiab ces undergo tshuaj tiv thaiv kom tiav cov zaj duab xis loj hlob.

Raws li qhov zaus ntawm plasma tiam, cov plasma siv hauv PECVD tuaj yeem muab faib ua ob hom: xov tooj cua zaus plasma (RF plasma) thiab microwave plasma (Microwave plasma). Tam sim no, lub xov tooj cua zaus siv hauv kev lag luam feem ntau yog 13.56MHz.

Kev taw qhia ntawm xov tooj cua zaus plasma feem ntau muab faib ua ob hom: capacitive coupling (CCP) thiab inductive coupling (ICP). Txoj kev capacitive coupling feem ntau yog cov tshuaj tiv thaiv ntshav ncaj qha; thaum txoj kev inductive coupling tuaj yeem yog txoj kev ncaj qha plasma lossis txoj kev plasma tej thaj chaw deb.

Hauv cov txheej txheem tsim khoom semiconductor, PECVD feem ntau yog siv los loj hlob cov yeeb yaj kiab nyias ntawm cov substrates uas muaj hlau lossis lwm cov qauv kub-rhiab heev. Piv txwv li, nyob rau hauv lub teb ntawm back-end hlau interconnection ntawm integrated circuits, txij li thaum lub hauv paus, lub rooj vag thiab ntws lug ntawm cov cuab yeej tau tsim nyob rau hauv cov txheej txheem pem hauv ntej-kawg, kev loj hlob ntawm nyias films nyob rau hauv lub tshav pob ntawm hlau interconnection yog raug. kom nruj heev thermal kev txwv, yog li nws feem ntau ua tiav nrog kev pab plasma. Los ntawm kev kho cov txheej txheem plasma, qhov ceev, tshuaj lom neeg muaj pes tsawg leeg, cov ntsiab lus impurity, mechanical toughness thiab stress parameters ntawm nyias zaj duab xis loj hlob los ntawm PECVD tuaj yeem hloov kho thiab ua kom zoo dua nyob rau hauv qee qhov ntau.

3.9 Atomic Layer Deposition Equipment

Atomic txheej deposition (ALD) yog ib tug nyias zaj duab xis deposition tshuab uas loj hlob raws sij hawm nyob rau hauv daim ntawv ntawm ib tug quasi-monoatomic txheej. Nws cov yam ntxwv yog tias cov tuab ntawm cov yeeb yaj kiab tso tawm tuaj yeem raug kho los ntawm kev tswj cov lej ntawm kev loj hlob. Tsis zoo li cov tshuaj vapor deposition (CVD) txheej txheem, ob (los yog ntau tshaj) precursors nyob rau hauv cov txheej txheem ALD alternately hla lub substrate nto thiab raug cais zoo los ntawm kev tshem tawm cov pa roj tsawg.

Ob lub precursors yuav tsis sib tov thiab sib ntsib nyob rau hauv cov roj theem kom reacts chemically, tab sis tsuas yog hnov los ntawm tshuaj adsorption ntawm lub substrate nto. Nyob rau hauv txhua lub voj voog ALD, tus nqi ntawm precursor adsorbed ntawm lub substrate nto muaj feem xyuam rau qhov ceev ntawm cov active pab pawg nyob rau hauv substrate nto. Thaum cov pab pawg reactive nyob rau hauv lub substrate nto yog tas, txawm tias ib tug ntau tshaj ntawm precursor yog qhia, tshuaj adsorption yuav tsis tshwm sim nyob rau hauv lub substrate nto.

Cov txheej txheem tshuaj tiv thaiv no yog hu ua cov tshuaj tiv thaiv tus kheej-limiting nto. Cov txheej txheem txheej txheem no ua rau lub thickness ntawm cov zaj duab xis loj hlob nyob rau hauv txhua lub voj voog ntawm cov txheej txheem ALD tas li, yog li cov txheej txheem ALD muaj qhov zoo ntawm cov tuab tuab tswj thiab cov txheej txheem zaj duab xis zoo.

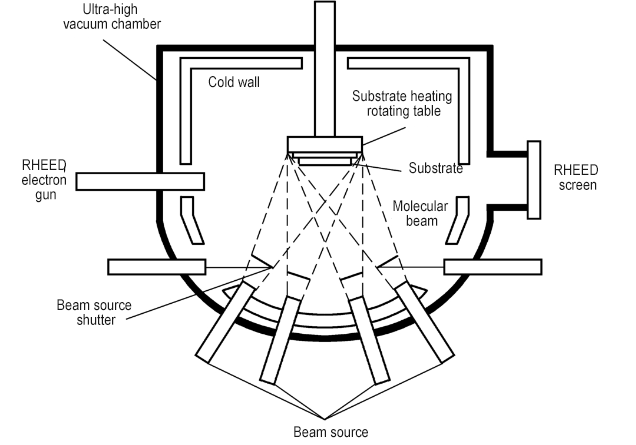

3.10 Molecular Beam Epitaxy Cov Khoom Siv

Molecular Beam Epitaxy (MBE) system yog hais txog ib qho khoom siv epitaxial uas siv ib lossis ntau dua thermal zog atomic beams los yog molecular beams los tshuaj tsuag mus rau lub rhuab substrate nto ntawm ib tug tej yam ceev nyob rau hauv ultra-high nqus tej yam kev mob, thiab adsorb thiab migrate nyob rau hauv lub substrate nto. mus rau epitaxially loj hlob ib leeg siv lead ua nyias zaj duab xis raws cov siv lead ua axis kev taw qhia ntawm cov khoom siv substrate. Feem ntau, nyob rau hauv cov xwm txheej ntawm cua sov los ntawm lub dav hlau cub tawg nrog lub tshav kub tiv thaiv, lub beam qhov chaw tsim ib tug atomic beam los yog ib tug molecular beam, thiab cov zaj duab xis loj hlob txheej los ntawm txheej raws li crystal axis kev taw qhia ntawm cov khoom siv substrate.

Nws cov yam ntxwv yog qhov qis epitaxial loj hlob kub, thiab lub thickness, interface, tshuaj muaj pes tsawg leeg thiab impurity concentration yuav precisely tswj nyob rau hauv lub atomic theem. Txawm hais tias MBE pib los ntawm kev npaj ntawm semiconductor ultra-thin ib leeg siv lead ua zaj duab xis, nws daim ntawv thov tam sim no tau nthuav dav rau ntau yam khoom siv xws li hlau thiab insulating dielectrics, thiab tuaj yeem npaj III-V, II-VI, silicon, silicon germanium (SiGe) ), graphene, oxides thiab organic films.

Cov kab hluav taws xob molecular epitaxy (MBE) feem ntau yog tsim los ntawm lub tshuab nqus tsev ultra-siab, ib qho khoom siv hluav taws xob molecular, lub substrate kho thiab cua sov, cov qauv hloov pauv, qhov ntsuas hauv qhov chaw, kev tswj xyuas, thiab kev sim. qhov system.

Lub tshuab nqus tsev muaj xws li lub tshuab nqus tsev twj (cov twj siv tshuab, lub twj tso kua mis molecular, ion twj, thiab cov twj tso kua mis, thiab lwm yam) thiab ntau yam li qub, uas tuaj yeem tsim kom muaj kev loj hlob ntawm lub tshuab nqus tsev. Lub tshuab nqus tsev feem ntau ua tiav yog 10-8 txog 10-11 Torr. Lub tshuab nqus tsev feem ntau muaj peb lub tshuab nqus tsev ua haujlwm, uas yog cov qauv txhaj tshuaj chamber, pretreatment thiab deg tsom xam chamber, thiab kev loj hlob chamber.

Cov qauv txhaj tshuaj chamber yog siv los hloov cov qauv mus rau lub ntiaj teb sab nraud kom ntseeg tau tias lub tshuab nqus tsev siab ntawm lwm chav; lub pretreatment thiab deg soj ntsuam chamber txuas cov qauv txhaj tshuaj chamber thiab cov kev loj hlob chamber, thiab nws lub luag hauj lwm tseem ceeb yog ua ntej ua cov qauv (high-temperature degassing los xyuas kom meej lub tiav huv si ntawm substrate nto) thiab ua ntej kev soj ntsuam nto ntawm lub huv qauv; Qhov kev loj hlob chamber yog qhov tseem ceeb ntawm MBE system, feem ntau yog tsim los ntawm lub qhov cub thiab nws qhov sib txuas ntawm lub kaw lus sib dhos, cov qauv tswj lub console, lub tshuab ua kom txias, lub zog muaj zog electron diffraction (RHEED), thiab kev saib xyuas hauv qhov chaw. . Qee cov khoom siv MBE ntau lawm muaj ntau yam kev loj hlob chamber configuration. Daim duab schematic ntawm MBE cov cuab yeej siv tau qhia hauv qab no:

MBE ntawm silicon cov ntaub ntawv siv high-purity silicon raws li raw khoom, hlob nyob rau hauv ultra-high nqus (10-10 ~ 10-11Torr), thiab kev loj hlob kub yog 600 ~ 900 ℃, nrog Ga (P-hom) thiab Sb ( N-type) raws li qhov chaw doping. Feem ntau siv doping qhov chaw xws li P, As thiab B tsis tshua siv los ua cov khoom siv hluav taws xob vim tias lawv nyuaj rau evaporate.

Cov tshuaj tiv thaiv chamber ntawm MBE muaj ib puag ncig ultra-high nqus, uas ua rau kom txoj hauv kev tsis pub dawb ntawm cov molecules thiab txo cov kab mob thiab oxidation ntawm cov khoom loj hlob. Cov khoom siv epitaxial npaj muaj qhov zoo ntawm qhov chaw morphology thiab uniformity, thiab tuaj yeem ua rau hauv cov qauv sib txawv nrog cov khoom sib txawv lossis cov khoom sib txawv.

MBE thev naus laus zis ua tiav qhov kev loj hlob zuj zus ntawm ultra-thin epitaxial txheej nrog lub thickness ntawm ib txheej atomic, thiab kev sib tshuam ntawm cov txheej epitaxial yog ntxhab. Nws txhawb txoj kev loj hlob ntawm III-V semiconductors thiab lwm yam khoom siv ntau yam heterogeneous. Tam sim no, MBE system tau dhau los ua cov cuab yeej ua haujlwm siab heev rau kev tsim cov khoom siv microwave tshiab thiab cov khoom siv optoelectronic. Qhov tsis zoo ntawm MBE thev naus laus zis yog qhov kev loj hlob ntawm zaj duab xis qeeb, qhov xav tau ntawm lub tshuab nqus tsev siab, thiab cov cuab yeej siv siab thiab cov cuab yeej siv.

3.11 Vapor Phase Epitaxy System

Lub vapor theem epitaxy (VPE) system yog hais txog ib qho kev loj hlob ntawm epitaxial khoom uas thauj cov pa roj carbon monoxide mus rau lub substrate thiab tau txais ib qho khoom siv lead ua ib txheej nrog tib lub lattice kev npaj raws li cov substrate los ntawm cov tshuaj tiv thaiv. Cov txheej txheem epitaxial tuaj yeem yog homoepitaxial txheej (Si / Si) lossis txheej heteroepitaxial (SiGe / Si, SiC / Si, GaN / Al2O3, thiab lwm yam). Tam sim no, VPE thev naus laus zis tau siv dav hauv kev npaj nanomaterial, cov khoom siv hluav taws xob, cov khoom siv hluav taws xob semiconductor optoelectronic, hnub ci photovoltaics, thiab kev sib koom ua ke.

Hom VPE muaj xws li atmospheric siab epitaxy thiab txo siab epitaxy, ultra-high nqus tshuaj vapor deposition, hlau organic chemical vapor deposition, thiab lwm yam. Cov ntsiab lus tseem ceeb hauv VPE tshuab yog cov tshuaj tiv thaiv chamber tsim, roj ntws hom thiab uniformity, kub uniformity thiab precision tswj, siab tswj thiab stability, particle thiab tsis xws luag tswj, thiab lwm yam.

Tam sim no, txoj kev loj hlob ntawm kev lag luam tseem ceeb VPE systems yog loj wafer loading, tag nrho tsis siv neeg tswj, thiab real-time saib xyuas ntawm kub thiab loj hlob txheej txheem. VPE systems muaj peb yam: ntsug, kab rov tav thiab cylindrical. Cov txheej txheem cua sov muaj xws li cov cua kub tsis kam, siab zaus induction cua sov thiab infrared hluav taws xob cua sov.

Tam sim no, VPE systems feem ntau siv kab rov tav disc qauv, uas muaj cov yam ntxwv zoo sib xws ntawm epitaxial zaj duab xis loj hlob thiab loj wafer loading. VPE systems feem ntau muaj plaub ntu: reactor, cua sov system, gas system system thiab tswj system. Vim tias lub sij hawm loj hlob ntawm GaAs thiab GaN epitaxial films yog qhov ntev, induction cua sov thiab cua sov feem ntau yog siv. Nyob rau hauv silicon VPE, tuab epitaxial zaj duab xis loj hlob feem ntau siv induction cua sov; nyias epitaxial zaj duab xis loj hlob feem ntau yog siv cov cua sov infrared kom ua tiav lub hom phiaj ntawm kev kub ceev ceev / poob.

3.12 Liquid Phase Epitaxy System

Liquid Phase Epitaxy (LPE) system hais txog cov khoom siv kev loj hlob ntawm epitaxial uas yaj cov khoom yuav loj hlob (xws li Si, Ga, As, Al, thiab lwm yam) thiab dopants (xws li Zn, Te, Sn, thiab lwm yam) hauv ib hlau nrog ib tug qis melting point (xws li Ga, In, thiab lwm yam), kom lub solute yog saturated los yog supersaturated nyob rau hauv cov kuab tshuaj, thiab ces ib tug crystal substrate yog hu nrog kev daws, thiab cov kuab tshuaj yog precipitated los ntawm cov kuab tshuaj los ntawm maj mam txias, thiab ib txheej ntawm cov khoom siv lead ua nrog cov qauv siv lead ua thiab cov lattice tsis tu ncua zoo ib yam li cov substrate yog loj hlob nyob rau saum npoo ntawm substrate.

Txoj kev LPE tau thov los ntawm Nelson li al. xyoo 1963. Nws yog siv los loj hlob Si nyias zaj duab xis thiab cov khoom siv lead ua ib leeg, nrog rau cov khoom siv semiconductor xws li III-IV pawg thiab mercury cadmium telluride, thiab tuaj yeem siv los ua ntau yam khoom siv optoelectronic, cov khoom siv microwave, cov khoom siv semiconductor thiab cov hnub ci hlwb. .

———————————————————————————————————————————————————————— ————————————————

Semicera tuaj yeem muab taugraphite qhov chaw, soft/rigid xav, silicon carbide qhov chaw, CVD silicon carbide qhov chaw, thiabSiC/TaC coated qhov chawnrog hauv 30 hnub.

Yog tias koj txaus siab rau cov khoom lag luam semiconductor saum toj no,thov tsis txhob yig tiv tauj peb thawj zaug.

Tel: +86-13373889683

WhatsApp: +86-15957878134

Email: sales01@semi-cera.com

Post lub sij hawm: Aug-31-2024