Wafers yog cov khoom siv tseem ceeb rau kev tsim cov khoom siv hluav taws xob sib txuas, cov khoom siv hluav taws xob sib cais thiab cov khoom siv hluav taws xob. Ntau tshaj 90% ntawm cov kev sib txuas ua ke yog tsim los ntawm cov khoom siv purity siab, zoo wafers.

Wafer npaj cov cuab yeej hais txog cov txheej txheem ntawm kev ua cov ntaub ntawv ntshiab polycrystalline silicon rau hauv silicon ib leeg siv lead ua qws cov ntaub ntawv ntawm ib txoj kab uas hla thiab ntev, thiab tom qab ntawd muab cov khoom siv silicon ib leeg siv lead ua rau cov khoom siv kho tshuab, kev kho tshuaj thiab lwm yam txheej txheem.

Cov khoom siv uas tsim cov silicon wafers lossis epitaxial silicon wafers uas ua tau raws li qee qhov geometric raug thiab qhov yuav tsum tau ua kom zoo thiab muab cov khoom siv silicon substrate rau chip manufacturing.

Cov txheej txheem raug cai rau kev npaj silicon wafers nrog lub cheeb ntawm tsawg dua 200 mm yog:

Ib leeg siv lead ua kev loj hlob → truncation → txheej txoj kab uas hla dov → slicing → chamfering → sib tsoo → etching → gettering → polishing → tu → epitaxy → ntim, thiab lwm yam.

Cov txheej txheem tseem ceeb rau kev npaj silicon wafers nrog lub cheeb ntawm 300 mm yog raws li nram no:

Ib leeg siv lead ua loj hlob → truncation → txheej txoj kab uas hla dov → slicing → chamfering → nto sib tsoo → etching → ntug polishing → ob-sided polishing → ib sab polishing → kawg tu → epitaxy / annealing → ntim, thiab lwm yam.

1.Silicon khoom

Silicon yog cov khoom siv semiconductor vim nws muaj 4 valence electrons thiab yog nyob rau hauv pawg IVA ntawm lub sij hawm nrog rau lwm yam.

Tus naj npawb ntawm valence electrons nyob rau hauv silicon muab nws nyob rau hauv nruab nrab ntawm ib tug zoo conductor (1 valence electron) thiab ib tug insulator (8 valence electrons).

Ntshiab silicon tsis pom nyob rau hauv cov xwm thiab yuav tsum tau muab rho tawm thiab purified kom nws ntshiab txaus rau manufacturing. Nws feem ntau pom muaj nyob hauv silica (silicon oxide lossis SiO2) thiab lwm yam silicates.

Lwm cov ntaub ntawv ntawm SiO2 suav nrog iav, tsis muaj xim siv lead ua, quartz, agate thiab miv lub qhov muag.

Thawj cov khoom siv los ua ib lub semiconductor yog germanium hauv xyoo 1940 thiab thaum ntxov xyoo 1950, tab sis nws tau hloov sai sai los ntawm silicon.

Silicon tau raug xaiv los ua cov khoom siv semiconductor rau plaub lub laj thawj:

Kev nplua nuj ntawm cov khoom siv silicone: Silicon yog qhov thib ob uas muaj ntau tshaj plaws hauv ntiaj teb, suav txog 25% ntawm lub ntiaj teb pob zeb.

Lub melting point ntau dua ntawm cov khoom siv silicon tso cai rau cov txheej txheem dav dua: lub melting point ntawm silicon ntawm 1412 ° C yog ntau dua li melting point ntawm germanium ntawm 937 ° C. Qhov siab melting point tso cai rau silicon tiv taus cov txheej txheem kub.

Cov khoom siv silicone muaj qhov dav dav ntawm kev ua haujlwm kub;

Ntuj kev loj hlob ntawm silicon oxide (SiO2): SiO2 yog cov khoom siv hluav taws xob zoo, ruaj khov hluav taws xob thiab ua raws li cov tshuaj tiv thaiv zoo heev los tiv thaiv silicon los ntawm kev sib kis sab nraud. Kev ruaj ntseg hluav taws xob yog qhov tseem ceeb kom tsis txhob xau ntawm cov neeg nyob ib sab hauv kev sib koom ua ke. Lub peev xwm loj hlob ruaj khov nyias txheej ntawm SiO2 cov khoom siv yog qhov tseem ceeb rau kev tsim cov khoom siv hlau-oxide semiconductor (MOS-FET). SiO2 muaj cov khoom zoo sib xws rau silicon, tso cai rau kev ua haujlwm kub tsis muaj silicon wafer warping ntau dhau.

2. Kev npaj wafer

Semiconductor wafers raug txiav los ntawm cov khoom siv semiconductor ntau. Cov khoom siv semiconductor no yog hu ua lub pas nrig siv lead ua, uas yog zus los ntawm ib qho loj ntawm polycrystalline thiab undoped intrinsic khoom.

Hloov cov polycrystalline block rau hauv ib lub pob zeb loj loj thiab muab nws qhov tseeb siv lead ua kev taw qhia thiab qhov tsim nyog ntawm N-hom lossis P-hom doping yog hu ua crystal kev loj hlob.

Cov thev naus laus zis ntau tshaj plaws rau kev tsim ib qho siv lead ua silicon ingots rau kev npaj silicon wafer yog Czochralski txoj kev thiab cov txheej txheem zone melting.

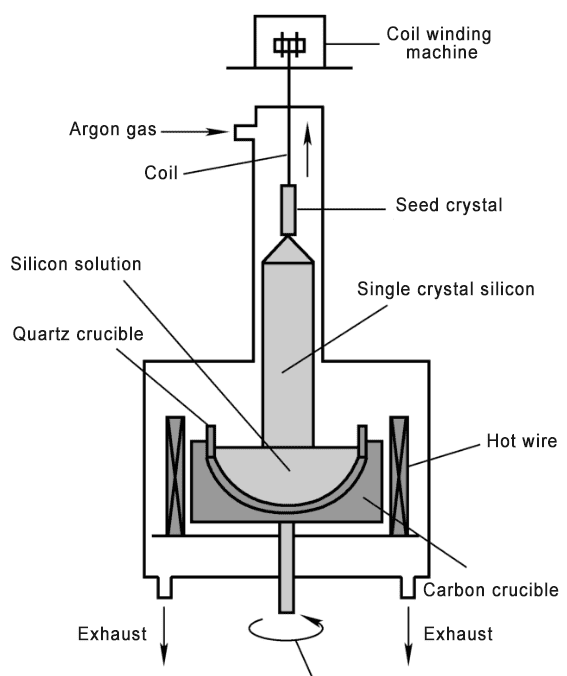

2.1 Czochralski txoj kev thiab Czochralski ib leeg siv lead ua rauv

Czochralski (CZ) txoj kev, tseem hu ua Czochralski (CZ) txoj kev, hais txog cov txheej txheem ntawm kev hloov molten semiconductor-qib silicon kua rau hauv cov khoom siv lead ua silicon ingots nrog qhov tseeb siv lead ua thiab doped rau hauv N-hom lossis P- hom.

Tam sim no, ntau dua 85% ntawm ib leeg siv lead ua silicon yog zus siv Czochralski txoj kev.

Czochralski ib leeg siv lead ua rauv yog hais txog cov txheej txheem cov khoom siv uas melts high-purity polysilicon cov ntaub ntawv rau hauv cov kua los ntawm cua sov nyob rau hauv ib tug kaw lub tshuab nqus tsev vacuum los yog tsis tshua muaj roj (los yog inert gas) tiv thaiv ib puag ncig, thiab ces recrystallizes lawv los ua ib tug siv lead ua silicon cov ntaub ntawv nrog rau tej yam sab nraud. qhov ntev.

Lub hauv paus ntsiab lus ntawm kev ua haujlwm ntawm ib lub qhov cub siv lead ua yog cov txheej txheem lub cev ntawm cov khoom siv polycrystalline silicon recrystallizing rau hauv ib qho khoom siv lead ua silicon hauv cov kua hauv lub xeev.

CZ ib leeg siv lead ua rauv tuaj yeem muab faib ua plaub ntu: lub tshuab ua kom sov lub cev, cov tshuab xa hluav taws xob, cua sov thiab kub tswj qhov system, thiab cov roj xa hluav taws xob.

Lub tshuab hluav taws xob lub cev muaj xws li lub qhov cub hluav taws xob, cov noob siv lead ua axis, quartz crucible, ib rab diav doping, cov noob siv lead ua npog, thiab lub qhov rais soj ntsuam.

Lub tshuab ua kom sov yog ua kom ntseeg tau tias qhov ntsuas kub hauv lub cub tawg yog sib npaug thiab tuaj yeem ua kom sov tau zoo; cov noob siv lead ua ncej yog siv los tsav cov noob siv lead ua kom txav mus thiab nqis thiab tig; cov impurities uas yuav tsum tau doped yog muab tso rau hauv lub doping diav;

Cov noob siv lead ua npog yog los tiv thaiv cov noob siv lead ua los ntawm kev sib kis. Lub tshuab xa hluav taws xob feem ntau yog siv los tswj kev txav ntawm cov noob siv lead ua thiab cov crucible.

Txhawm rau kom ntseeg tau tias cov tshuaj silicon tsis yog oxidized, lub tshuab nqus tsev hauv qhov cub yuav tsum siab heev, feem ntau qis dua 5 Torr, thiab qhov purity ntawm cov roj inert ntxiv yuav tsum siab tshaj 99.9999%.

Ib daim ntawm ib qho siv lead ua silicon nrog rau qhov xav tau siv lead ua kev taw qhia yog siv los ua cov noob siv lead ua kom loj hlob silicon ingot, thiab cov silicon ingot loj hlob zoo li cov qauv ntawm cov noob siv lead ua.

Cov xwm txheej ntawm qhov sib cuam tshuam ntawm molten silicon thiab ib qho siv lead ua silicon noob siv lead ua yuav tsum tau tswj kom meej. Cov xwm txheej no ua kom ntseeg tau tias cov txheej nyias nyias ntawm silicon tuaj yeem ua raws li cov qauv ntawm cov noob siv lead ua thiab nws thiaj li loj hlob mus rau hauv ib qho loj siv lead ua silicon ingot.

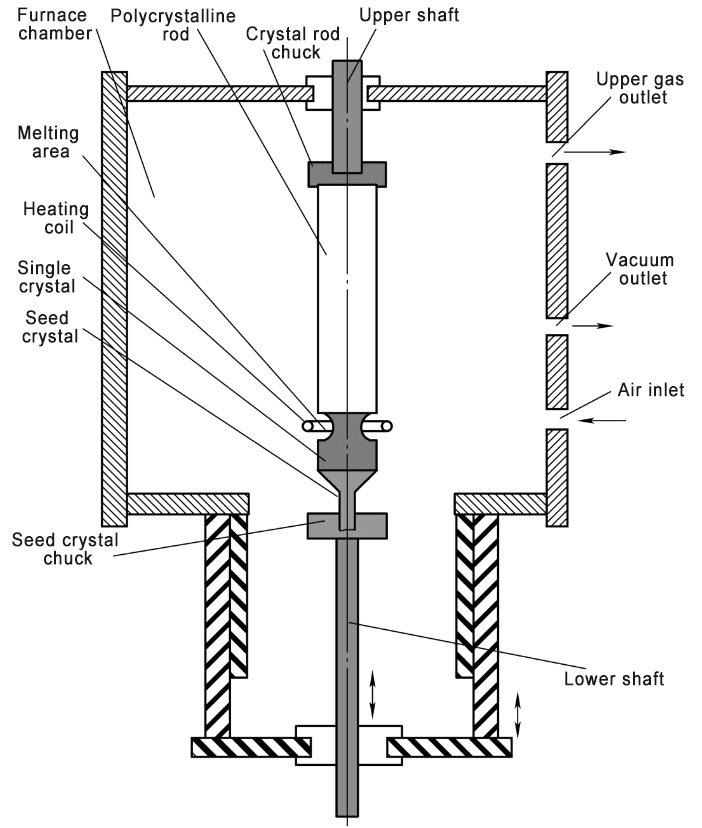

2.2 Zone Melting Method thiab Zone Melting Ib Leeg Crystal Rauv

Txoj kev float zone method (FZ) tsim ib qho siv lead ua silicon ingots nrog cov ntsiab lus oxygen tsawg heev. Txoj kev float zone tau tsim nyob rau xyoo 1950 thiab tuaj yeem tsim cov khoom siv lead ua silicon rau hnub tim.

Thaj chaw melting ib leeg siv lead ua rauv yog hais txog lub cub tawg uas siv lub hauv paus ntsiab lus ntawm cheeb tsam melting los tsim ib qho chaw nqaim melting hauv cov pas nrig polycrystalline los ntawm qhov kub-kub nqaim kaw thaj tsam ntawm polycrystalline qws rauv lub cev hauv lub tshuab nqus tsev siab lossis tsis tshua muaj quartz raj roj. kev tiv thaiv ib puag ncig.

Cov khoom siv txheej txheem uas txav tau lub pas nrig polycrystalline los yog lub tshuab cua sov lub cev kom txav mus rau qhov chaw melting thiab maj mam crystallize nws mus rau hauv ib lub pas nrig.

Cov yam ntxwv ntawm kev npaj ib leeg siv lead ua rods los ntawm cheeb tsam melting txoj kev yog hais tias purity ntawm polycrystalline rods tuaj yeem txhim kho nyob rau hauv tus txheej txheem ntawm crystallization rau hauv ib qho siv lead ua rods, thiab doping kev loj hlob ntawm cov ntaub ntawv pas nrig yog ntau yam.

Cov hom ntawm cheeb tsam melting ib leeg siv lead ua rauv tuaj yeem muab faib ua ob hom: floating zones melting ib leeg siv lead ua rauv uas vam khom qhov nro thiab kab rov tav zone melting ib qho crystal furnaces. Hauv kev siv cov tswv yim, thaj tsam melting ib leeg siv lead ua rauv feem ntau txais yuav ntab zone melting.

Lub cheeb tsam melting ib leeg siv lead ua rauv tuaj yeem npaj high-purity low-oxygen ib leeg siv lead ua silicon yam tsis tas yuav muaj lub crucible. Nws yog tsuas yog siv los npaj high-resistivity (> 20kΩ·cm) ib leeg siv lead ua silicon thiab purify cheeb tsam melting silicon. Cov khoom no tsuas yog siv rau hauv kev tsim cov khoom siv hluav taws xob sib cais.

Lub cheeb tsam melting ib leeg siv lead ua rauv muaj xws li lub cub tawg chamber, lub sab sauv ncej thiab ib tug qis ncej (mechanical kis tau tus mob ib feem), ib tug siv lead ua qws chuck, ib tug noob siv lead ua chuck, lub cua sov coil (siab zaus generator), roj ports (chaw nres nkoj nqus tsev vacuum, gas inlet, lub qhov hluav taws xob sab sauv), thiab lwm yam.

Nyob rau hauv lub cub tawg chamber qauv, txias dej ncig yog teem. Qhov qis kawg ntawm lub taub hau sab saud ntawm lub qhov cub siv lead ua ib leeg yog siv lead ua chuck chuck, uas yog siv los clamp lub pas nrig polycrystalline; sab saum toj kawg ntawm lub hauv qab ncej yog cov noob siv lead ua chuck, uas yog siv los clamp cov noob siv lead ua.

Lub tshuab hluav taws xob ntau zaus yog muab rau cov cua sov coil, thiab qhov chaw nqaim melting yog tsim nyob rau hauv cov pas nrig polycrystalline pib los ntawm qis kawg. Nyob rau tib lub sij hawm, lub sab sauv thiab sab axes tig thiab nqis, kom lub melting cheeb tsam yog crystallized rau hauv ib tug siv lead ua.

Qhov zoo ntawm thaj tsam melting ib qho siv lead ua rauv yog tias nws tuaj yeem tsis tsuas yog txhim kho qhov purity ntawm ib leeg siv lead ua, tab sis kuj ua rau tus pas nrig doping kev loj hlob zoo ib yam, thiab ib qho siv lead ua pas nrig tuaj yeem ua kom huv los ntawm ntau yam txheej txheem.

Qhov tsis zoo ntawm thaj tsam melting ib leeg siv lead ua rauv yog cov txheej txheem siab cov nqi thiab cov kab me me ntawm cov khoom siv ib leeg npaj. Tam sim no, qhov siab tshaj plaws txoj kab uas hla ntawm ib qho siv lead ua uas tuaj yeem npaj tau yog 200mm.

Tag nrho qhov siab ntawm cheeb tsam melting ib leeg siv lead ua rauv khoom yog qhov siab, thiab cov hlab ntsha ntawm lub qaum thiab sab qis yog qhov ntev, yog li ntev ib leeg siv lead ua rods tuaj yeem loj hlob.

3. Wafer ua thiab khoom siv

Cov pas nrig siv lead ua yuav tsum tau mus dhau los ntawm cov txheej txheem los tsim cov silicon substrate uas ua tau raws li cov kev cai ntawm kev tsim khoom semiconductor, uas yog lub wafer. Lub hauv paus txheej txheem ntawm kev ua yog:

Tumbling, txiav, slicing, wafer annealing, chamfering, sib tsoo, polishing, tu thiab ntim, thiab lwm yam.

3.1 Wafer Annealing

Nyob rau hauv cov txheej txheem ntawm kev tsim polycrystalline silicon thiab Czochralski silicon, ib qho siv lead ua silicon muaj cov pa oxygen. Ntawm qhov kub thiab txias, cov pa oxygen hauv ib qho siv lead ua silicon yuav pub cov khoom siv hluav taws xob, thiab cov pa oxygen yuav hloov mus rau cov neeg pub oxygen. Cov electrons no yuav ua ke nrog impurities nyob rau hauv silicon wafer thiab cuam tshuam cov resistivity ntawm silicon wafer.

Annealing furnace: yog hais txog lub qhov cub uas ua kom qhov kub thiab txias hauv lub cub tawg mus rau 1000-1200 ° C hauv ib puag ncig hydrogen lossis argon. Los ntawm kev ua kom sov thiab txias, cov pa oxygen nyob ze ntawm qhov chaw ntawm polished silicon wafer yog volatilized thiab tshem tawm ntawm nws qhov chaw, ua rau cov pa oxygen rau precipitate thiab txheej.

Cov txheej txheem cov cuab yeej ua kom yaj micro defects ntawm qhov chaw ntawm silicon wafers, txo cov impurities nyob ze ntawm qhov chaw ntawm silicon wafers, txo qhov tsis xws luag, thiab tsim ib qho chaw huv si ntawm silicon wafers.

Lub qhov cub annealing tseem hu ua lub qhov cub kub kub vim nws qhov kub thiab txias. Kev lag luam kuj hu ua silicon wafer annealing txheej txheem gettering.

Silicon wafer annealing rauv muab faib ua:

- Kab rov tav annealing rauv;

- Vertical annealing rauv;

-Rapid annealing rauv.

Qhov sib txawv tseem ceeb ntawm kab rov tav annealing rauv thiab ntsug annealing rauv yog qhov kev taw qhia ntawm cov tshuaj tiv thaiv chamber.

Cov tshuaj tiv thaiv chamber ntawm kab rov tav annealing rauv yog kab rov tav, thiab ib pawg ntawm silicon wafers tuaj yeem thauj mus rau hauv cov tshuaj tiv thaiv chamber ntawm lub qhov cub annealing rau tib lub sijhawm. Lub sijhawm annealing feem ntau yog 20 mus rau 30 feeb, tab sis cov tshuaj tiv thaiv chamber xav tau lub sijhawm cua sov ntev dua kom ncav cuag qhov kub uas yuav tsum tau ua los ntawm cov txheej txheem annealing.

Cov txheej txheem ntawm ntsug annealing rauv kuj siv cov txheej txheem ntawm ib txhij loading ib batch ntawm silicon wafers rau hauv cov tshuaj tiv thaiv chamber ntawm lub annealing rauv rau annealing kev kho mob. Cov tshuaj tiv thaiv chamber muaj cov qauv ntsug, uas tso cai rau cov silicon wafers muab tso rau hauv lub nkoj quartz nyob rau hauv lub xeev kab rov tav.

Nyob rau tib lub sijhawm, txij li lub nkoj quartz tuaj yeem tig tag nrho hauv cov tshuaj tiv thaiv chamber, qhov ntsuas kub ntawm cov tshuaj tiv thaiv chamber tsis sib xws, qhov kub thiab txias ntawm cov silicon wafer yog qhov sib xws, thiab nws muaj cov yam ntxwv zoo sib xws. Txawm li cas los xij, cov txheej txheem tus nqi ntawm qhov ntsug annealing rauv yog siab dua li ntawm kab rov tav annealing rauv.

Lub tshuab hluav taws xob nrawm nrawm siv lub teeb halogen tungsten kom ncaj qha tshav kub ntawm silicon wafer, uas tuaj yeem ua tiav cov cua kub ceev los yog txias hauv ntau yam ntawm 1 txog 250 ° C / s. Qhov cua sov los yog cua txias yog ceev dua li ntawm cov tsoos annealing rauv. Nws tsuas yog siv ob peb vib nas this kom sov cov tshuaj tiv thaiv chamber kub kom siab tshaj 1100 ° C.

———————————————————————————————————————————————————————— ——

Semicera tuaj yeem muab taugraphite qhov chaw,soft/rigid xav,silicon carbide qhov chaw, CVD silicon carbide qhov chaw, thiabSiC/TaC coated qhov chawnrog tag nrho cov txheej txheem semiconductor hauv 30 hnub.

Yog tias koj txaus siab rau cov khoom lag luam semiconductor saum toj no, thov tsis txhob yig tiv tauj peb thawj zaug.

Tel: +86-13373889683

WhatsApp: +86-15957878134

Email: sales01@semi-cera.com

Post lub sij hawm: Aug-26-2024