Ntawm tag nrho cov txheej txheem koom nrog hauv kev tsim cov nti, txoj hmoo kawg ntawm tuswaferyog yuav tsum tau txiav rau hauv ib tug neeg tuag thiab ntim rau hauv me me, ntim thawv nrog tsuas yog ob peb pins raug. Lub nti yuav raug soj ntsuam raws li nws qhov pib, qhov tsis kam, qhov tam sim no, thiab qhov hluav taws xob, tab sis tsis muaj leej twg yuav xav txog nws qhov tsos. Thaum lub sij hawm tsim cov txheej txheem, peb pheej polish lub wafer kom ua tiav qhov tsim nyog planarization, tshwj xeeb tshaj yog rau txhua kauj ruam photolithography. Covwafernto yuav tsum tsis tshua muaj pav ca vim hais tias, raws li cov txheej txheem tsim chips shrinks, lub lens ntawm photolithography tshuab yuav tsum tau ua kom tiav nanometer-scale daws teeb meem los ntawm kev nce tus naj npawb aperture (NA) ntawm lub lens. Txawm li cas los xij, qhov no ib txhij txo qhov tob ntawm kev tsom xam (DoF). Qhov tob ntawm kev ua kom pom tseeb yog hais txog qhov tob uas lub tshuab kho qhov muag tuaj yeem tswj xyuas kom pom tseeb. Txhawm rau kom ntseeg tau tias cov duab photolithography tseem pom tseeb thiab ua kom pom tseeb, qhov txawv txav ntawm qhov chawwaferyuav tsum poob rau hauv qhov tob ntawm kev tsom xam.

Hauv cov ntsiab lus yooj yim, lub tshuab photolithography fij lub peev xwm los txhim kho cov duab precision. Piv txwv li, lub cim tshiab EUV photolithography tshuab muaj cov lej aperture ntawm 0.55, tab sis qhov ntsug qhov tob ntawm kev ua kom pom tseeb tsuas yog 45 nanometers, nrog rau qhov kev pom zoo me me thaum lub sijhawm photolithography. Yog tiaswafertsis yog tiaj tus, muaj qhov tsis sib xws, los yog nto undulations, nws yuav ua rau muaj teeb meem thaum photolithography ntawm cov ntsiab lus siab thiab qis.

Photolithography tsis yog tib txoj kev uas yuav tsum tau ua kom duwafernto. Ntau lwm cov txheej txheem tsim chip kuj xav tau wafer polishing. Piv txwv li, tom qab ntub dej etching, polishing yog xav tau kom du qhov ntxhib nto rau cov txheej tom ntej thiab tso tawm. Tom qab qhov kev sib cais trench ntiav (STI), polishing yuav tsum tau ua kom du cov silicon dioxide ntau dhau thiab ua kom tiav cov trench filling. Tom qab hlau deposition, polishing yog xav tau los tshem tawm cov txheej hlau ntau dhau thiab tiv thaiv cov khoom siv luv luv.

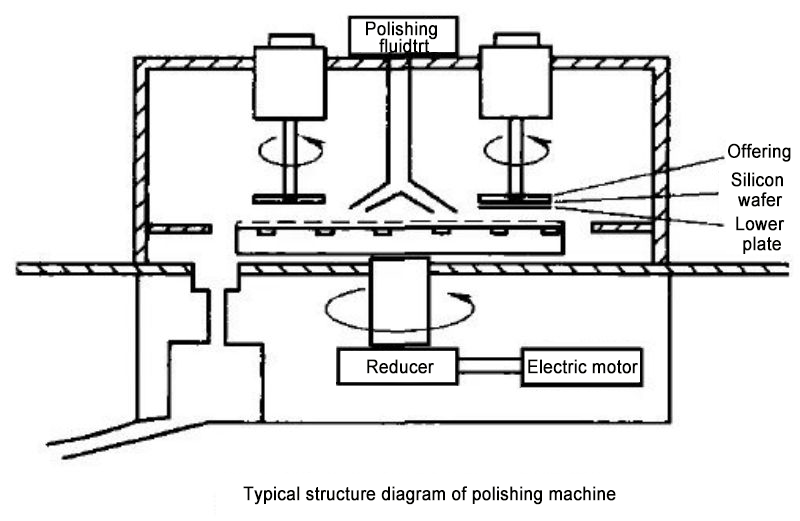

Yog li ntawd, kev yug me nyuam ntawm ib nti muaj ntau yam polishing cov kauj ruam los txo cov wafer roughness thiab deg variations thiab tshem tawm cov khoom ntau dhau ntawm qhov chaw. Tsis tas li ntawd, qhov tsis xws luag tshwm sim los ntawm ntau yam txheej txheem teeb meem ntawm wafer feem ntau tsuas yog tshwm sim tom qab txhua kauj ruam polishing. Yog li, cov engineers lub luag haujlwm rau polishing tuav lub luag haujlwm tseem ceeb. Lawv yog cov tseem ceeb hauv cov txheej txheem tsim cov chips thiab feem ntau dais lub txim hauv cov rooj sib tham ntau lawm. Lawv yuav tsum paub zoo nyob rau hauv ob qho tib si ntub dej etching thiab lub cev tso zis, raws li lub ntsiab polishing cov tswv yim hauv chip manufacturing.

Dab tsi yog txoj kev wafer polishing?

Cov txheej txheem polishing tuaj yeem muab faib ua peb pawg loj raws li kev sib cuam tshuam ntawm cov kua polishing thiab silicon wafer nto:

1. Mechanical Polishing Method:

Mechanical polishing tshem tawm cov polished nto protrusions los ntawm kev txiav thiab yas deformation kom ua tiav qhov chaw du. Cov cuab yeej siv feem ntau suav nrog cov pob zeb roj, cov log wool, thiab cov ntawv xuab zeb, feem ntau yog ua los ntawm tes. Cov khoom tshwj xeeb, xws li qhov chaw ntawm lub cev rotating, tuaj yeem siv turntables thiab lwm yam cuab yeej pabcuam. Rau qhov chaw uas yuav tsum tau ua kom zoo, super-fine polishing txoj kev tuaj yeem ua haujlwm. Super-fine polishing siv cov cuab yeej tshwj xeeb uas ua rau abrasive, uas, hauv cov kua nplaum uas muaj cov polishing, yog nruj nreem nias rau ntawm qhov chaw ntawm lub workpiece thiab tig ntawm kev kub ceev. Cov txheej txheem no tuaj yeem ua tiav qhov roughness ntawm Ra0.008μm, qhov siab tshaj plaws ntawm txhua txoj kev polishing. Txoj kev no feem ntau yog siv rau optical lens pwm.

2. Tshuaj Polishing Method:

Tshuaj polishing cuam tshuam qhov kev nyiam tshaj tawm ntawm micro-protrusions ntawm cov khoom nto hauv cov tshuaj nruab nrab, uas ua rau lub ntsej muag du. Qhov tseem ceeb ntawm txoj kev no yog qhov tsis xav tau cov cuab yeej siv nyuaj, muaj peev xwm ua kom zoo li cov workpieces, thiab muaj peev xwm polish ntau workpieces ib txhij nrog kev ua haujlwm siab. Lub ntsiab teeb meem ntawm tshuaj polishing yog cov formulation ntawm cov kua polishing. Qhov saum npoo roughness tiav los ntawm cov tshuaj polishing yog feem ntau ntau kaum ntawm micrometers.

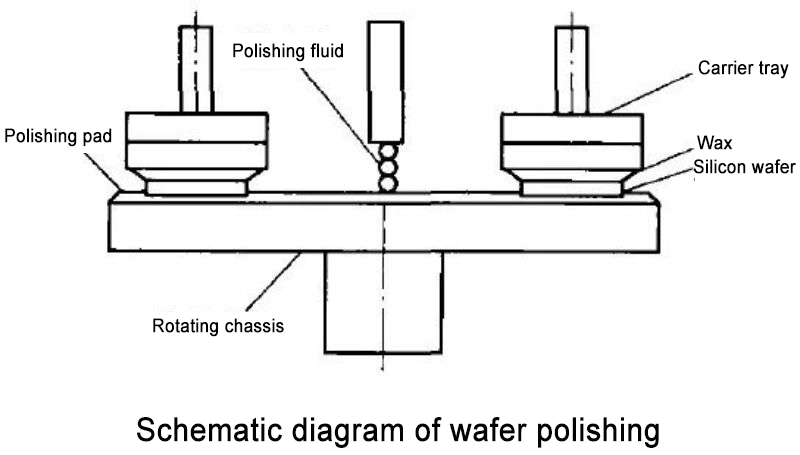

3. Tshuaj Mechanical Polishing (CMP) Txoj Kev:

Txhua tus thawj ob txoj kev polishing muaj nws qhov tshwj xeeb zoo. Kev sib koom ua ke ob txoj hauv kev no tuaj yeem ua tiav cov txiaj ntsig zoo hauv cov txheej txheem. Chemical mechanical polishing combines mechanical friction thiab chemical corrosion processes. Thaum lub sij hawm CMP, cov tshuaj reagents nyob rau hauv cov kua polishing oxidize lub polished substrate khoom, tsim ib tug mos oxide txheej. Cov txheej oxide no ces muab tshem tawm los ntawm kev sib txhuam. Rov ua dua cov txheej txheem oxidation thiab kev tshem tawm txhua yam ua tiav zoo polishing.

Cov teeb meem tam sim no thiab teeb meem hauv Chemical Mechanical Polishing (CMP):

CMP ntsib ntau yam teeb meem thiab teeb meem nyob rau hauv cov cheeb tsam ntawm technology, economics, thiab ib puag ncig sustainability:

1) Cov Txheej Txheem Zoo: Kev ua tiav siab sib xws hauv cov txheej txheem CMP tseem nyuaj. Txawm tias nyob rau hauv tib txoj kab ntau lawm, me me variations nyob rau hauv cov txheej txheem tsis sib txawv batches los yog cov khoom yuav cuam tshuam rau qhov kawg cov khoom sib xws.

2) Adaptability rau Cov Khoom Siv Tshiab: Raws li cov ntaub ntawv tshiab txuas ntxiv, CMP thev naus laus zis yuav tsum hloov mus rau lawv cov yam ntxwv. Qee cov ntaub ntawv qib siab yuav tsis sib haum nrog cov txheej txheem CMP ib txwm muaj, yuav tsum muaj kev txhim kho ntawm cov kua nplaum uas hloov tau ntau dua thiab cov abrasives.

3) Qhov cuam tshuam loj: Raws li cov khoom siv semiconductor qhov ntev txuas ntxiv zuj zus, cov teeb meem tshwm sim los ntawm qhov loj me ua qhov tseem ceeb. Qhov me me yuav tsum tau ua kom lub ntsej muag zoo dua, xav tau cov txheej txheem CMP ntau dua.

4) Kev Tswj Xyuas Kev Tshem Tawm Cov Khoom Siv: Hauv qee qhov kev siv, kev tswj xyuas meej ntawm cov khoom tshem tawm ntawm cov khoom sib txawv yog qhov tseem ceeb. Ua kom muaj kev tshem tawm zoo ib yam thoob plaws ntau txheej thaum CMP yog qhov tseem ceeb rau kev tsim cov cuab yeej ua haujlwm siab.

5) Environmental Friendliness: Cov kua polishing thiab abrasives siv hauv CMP tej zaum yuav muaj cov khoom tsis zoo. Kev tshawb nrhiav thiab kev txhim kho ntawm ntau tus phooj ywg ib puag ncig thiab kev ruaj ntseg CMP cov txheej txheem thiab cov ntaub ntawv yog qhov nyuaj heev.

6) Kev txawj ntse thiab Automation: Txawm hais tias kev txawj ntse thiab automation theem ntawm CMP cov tshuab tau maj mam txhim kho, lawv tseem yuav tsum tau tiv nrog qhov chaw tsim khoom nyuaj thiab sib txawv. Ua kom tiav qib siab ntawm automation thiab kev saib xyuas ntse los txhim kho kev tsim khoom yog qhov nyuaj uas yuav tsum tau daws.

7) Kev Tswj Tus Nqi: CMP suav nrog cov khoom siv siab thiab cov khoom siv. Cov neeg tsim khoom yuav tsum txhim kho cov txheej txheem kev ua tau zoo thaum siv zog los txo cov nqi tsim khoom los tswj kev lag luam kev sib tw.

Post lub sij hawm: Jun-05-2024