Silicon nitride (Si₃N₄) ceramics, raws li cov qauv txheej txheem siab heev, muaj cov khoom zoo xws li kub tsis kam, siab zog, siab toughness, siab hardness, creep resistance, oxidation tsis kam, thiab hnav tsis kam. Tsis tas li ntawd, lawv muaj cov thermal shock tsis kam, dielectric zog, siab thermal conductivity, thiab zoo heev high-frequency electromagnetic yoj kis tau tus mob. Cov cuab yeej zoo tshaj plaws no ua rau lawv tau siv dav hauv cov txheej txheem ua haujlwm nyuaj, tshwj xeeb tshaj yog nyob rau hauv aerospace thiab lwm yam khoom siv high-tech.

Txawm li cas los xij, Si₃N₄, ua ib qho kev sib xyaw nrog cov khoom sib txuas muaj zog, muaj cov qauv ruaj khov uas ua rau sintering rau siab ntom ntom nyuaj los ntawm cov khoom sib txawv hauv lub xeev ib leeg. Txhawm rau txhawb sintering, sintering pab, xws li hlau oxides (MgO, CaO, Al₂O₃) thiab tsawg lub ntiaj teb oxides (Yb₂O₃, Y₂O₃, Lu₂O₃, CeO₂), tau ntxiv los pab txhawb kev sib zog ntawm cov txheej txheem ua kua.

Tam sim no, lub ntiaj teb semiconductor ntaus ntawv thev naus laus zis tau nce mus rau qhov hluav taws xob ntau dua, cov dej ntws loj dua, thiab muaj zog ntau dua. Kev tshawb fawb rau hauv txoj kev rau fabricating Si₃N₄ ceramics yog dav. Kab lus no qhia txog cov txheej txheem sintering uas zoo txhim kho qhov ntom ntom thiab cov khoom siv dav dav ntawm silicon nitride ceramics.

Hom Sintering Methods rau Si₃N₄ Ceramics

Kev sib piv ntawm Kev Ua Haujlwm rau Si₃N₄ Ceramics Npaj los ntawm Kev Sib Txawv Sintering

1. Reactive Sintering (RS):Reactive sintering yog thawj txoj kev siv los ua lag luam npaj Si₃N₄ ceramics. Nws yog qhov yooj yim, tus nqi-zoo, thiab muaj peev xwm tsim cov duab complex. Txawm li cas los xij, nws muaj lub voj voog ntau lawm ntev, uas tsis tsim nyog rau kev tsim khoom lag luam.

2. Pressureless Sintering (PLS):Qhov no yog qhov yooj yim tshaj plaws thiab yooj yim sintering txheej txheem. Txawm li cas los xij, nws yuav tsum muaj cov ntaub ntawv zoo nkauj thiab feem ntau ua rau muaj kev ntoj me me nrog qis dua, tseem ceeb heev los yog deform.

3. Kub-Press Sintering (HP):Daim ntawv thov ntawm uniaxial mechanical siab tsub kom lub zog tsav rau sintering, cia ntom ntom ceramics yuav tsum tau ua nyob rau hauv kub ntawm 100-200 ° C qis dua cov uas siv nyob rau hauv pressureless sintering. Txoj kev no feem ntau yog siv rau fabricating kuj yooj yim thaiv-zoo li tus ceramics tab sis yog ib qho nyuaj rau ua tau raws li cov thickness thiab zoo li yuav tsum tau rau cov ntaub ntawv substrate.

4. Spark Plasma Sintering (SPS):SPS yog tus cwj pwm los ntawm kev ceev sintering, grain refinement, thiab txo sintering kub. Txawm li cas los xij, SPS xav tau kev nqis peev tseem ceeb hauv cov cuab yeej siv, thiab kev npaj siab thermal conductivity Si₃N₄ ceramics ntawm SPS tseem nyob rau theem kev sim thiab tseem tsis tau muaj kev lag luam.

5. Gas-Pressure Sintering (GPS):Los ntawm kev siv roj siab, txoj kev no inhibits ceramic decomposition thiab poob phaus ntawm qhov kub thiab txias. Nws yog qhov yooj yim dua los tsim cov khoom siv high-density ceramics thiab ua rau cov khoom tsim tawm. Txawm li cas los xij, ib kauj ruam roj-siab sintering txheej txheem tawm tsam los tsim cov khoom siv nrog cov xim sab hauv thiab sab nraud thiab cov qauv. Siv cov txheej txheem ob-kauj ruam lossis ntau kauj ruam sintering tuaj yeem txo cov ntsiab lus ntawm cov pa oxygen intergranular, txhim kho thermal conductivity, thiab txhim kho tag nrho cov khoom.

Txawm li cas los xij, qhov kub siab sintering ntawm ob-kauj ruam roj-siab sintering tau coj cov kev tshawb fawb yav dhau los los tsom feem ntau ntawm kev npaj Si₃N₄ ceramic substrates nrog cov thermal conductivity thiab chav kub kub dabtsi yog khoov lub zog. Kev tshawb fawb ntawm Si₃N₄ ceramics nrog cov khoom siv dav dav thiab cov khoom siv hluav taws xob kub kub yog qhov txwv.

Gas-Pressure Ob-Step Sintering Method rau Si₃N₄

Yang Zhou thiab cov npoj yaig los ntawm Chongqing University of Technology tau siv cov txheej txheem sintering ntawm 5 wt.% Yb₂O₃ + 5 wt.% Al₂O₃ los npaj Si₃N₄ ceramics siv ob theem thiab ob-kauj ruam roj-siab sintering txheej txheem ntawm 1800 ° C. Si₃N₄ ceramics tsim los ntawm ob-kauj ruam sintering txheej txheem muaj ntau dua ntom thiab zoo dua txhua yam khoom siv. Cov hauv qab no qhia txog cov teebmeem ntawm ib-kauj ruam thiab ob-kauj ruam roj-siab sintering txheej txheem ntawm microstructure thiab mechanical zog ntawm Si₃N₄ ceramic Cheebtsam.

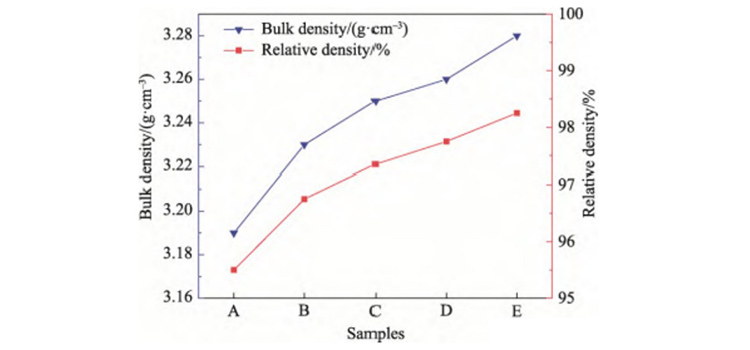

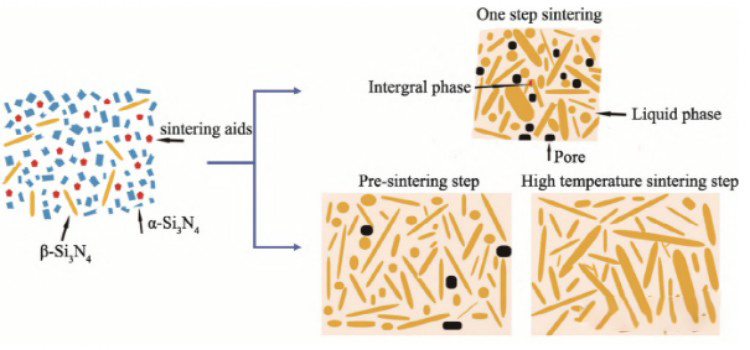

Density Cov txheej txheem densification ntawm Si₃N₄ feem ntau muaj peb theem, nrog sib tshooj ntawm cov theem. Thawj theem, particle rearrangement, thiab theem ob, dissolution-precipitation, yog cov theem tseem ceeb tshaj plaws rau densification. Lub sij hawm txaus cov tshuaj tiv thaiv nyob rau hauv cov theem no txhim kho cov qauv ntom. Thaum lub pre-sintering kub rau ob-kauj ruam sintering txheej txheem yog teem rau 1600 ° C, β-Si₃N₄ nplej tsim ib lub moj khaum thiab tsim kaw pores. Tom qab ua ntej sintering, ntxiv cua sov hauv qhov kub thiab txias thiab nitrogen siab txhawb cov kua-theem ntws thiab sau, uas pab tshem tawm cov pores kaw, ntxiv txhim kho qhov ntom ntawm Si₃N₄ ceramics. Yog li ntawd, cov qauv tsim los ntawm ob-kauj ruam sintering txheej txheem qhia ntau dua ntom ntom thiab txheeb ze ntom dua li cov uas ua los ntawm ib-kauj ruam sintering.

Theem thiab Microstructure Thaum lub sij hawm ib-kauj ruam sintering, lub sij hawm muaj rau particle rearrangement thiab grain ciam diffusion yog txwv. Nyob rau hauv ob-kauj ruam sintering txheej txheem, thawj kauj ruam yog ua nyob rau hauv qis kub thiab tsis tshua muaj roj siab, uas ncua lub particle rearrangement lub sij hawm thiab ua rau cov nplej loj. Tom qab ntawd qhov kub thiab txias tau nce mus rau theem siab kub, qhov twg cov nplej tseem loj hlob los ntawm Ostwald ripening txheej txheem, yielding high-density Si₃N₄ ceramics.

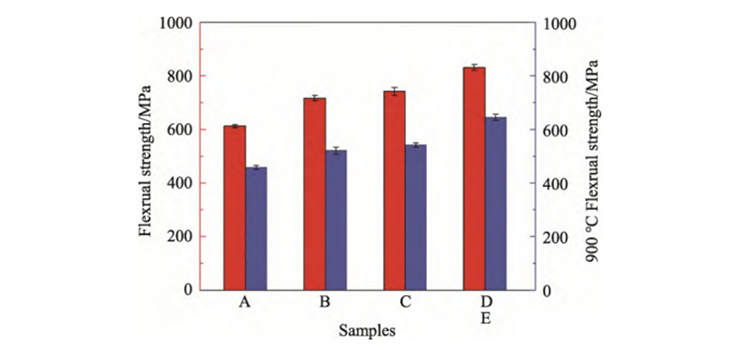

Mechanical Properties Lub softening ntawm lub intergranular theem nyob rau hauv high kub yog lub ntsiab yog vim li cas rau txo lub zog. Hauv ib-kauj ruam sintering, kev loj hlob tsis zoo ntawm cov nplej tsim cov pores me me ntawm cov nplej, uas tiv thaiv kev txhim kho tseem ceeb hauv qhov kub thiab txias. Txawm li cas los xij, nyob rau hauv ob-kauj ruam sintering txheej txheem, lub iav theem, uniformly faib nyob rau hauv lub grain ciam teb, thiab lub uniformly loj nplej txhim khu lub intergranular lub zog, uas ua rau lub high-temperature bending zog.

Hauv kev xaus, kev tuav ntev ntev thaum lub sij hawm ib-kauj ruam sintering tuaj yeem txo cov porosity sab hauv thiab ua tiav cov xim sab hauv thiab cov qauv tab sis tuaj yeem ua rau kev loj hlob tsis zoo, uas degrades qee yam khoom siv. Los ntawm kev siv ob-kauj ruam sintering txheej txheem-siv low-temperature pre-sintering kom ntev particle rearrangement lub sij hawm thiab high-temperature tuav los txhawb uniform grain loj hlob-ib Si₃N₄ ceramic nrog cov txheeb ze ntom ntom ntawm 98.25%, uniform microstructure, thiab zoo heev zoo txhua yam khoom. tuaj yeem npaj tiav.

| Lub npe | Substrate | Epitaxial txheej muaj pes tsawg leeg | Epitaxial txheej txheem | Epitaxial nruab nrab |

| Silicon homoepitaxial | Si | Si | Vapor Phase Epitaxy (VPE) | SiCl4+H2 |

| Silicon heteroepitaxial | Sapphire los yog spinel | Si | Vapor Phase Epitaxy (VPE) | SiH₄ + H₂ |

| GaAs homoepitaxial | GaAs | GaAs GaAs | Vapor Phase Epitaxy (VPE) | AsCl₃ + Ga + H₂ (Ar) |

| GaAs | GaAs GaAs | Molecular Beam Epitaxy (MBE) | Ga+As | |

| GaAs heteroepitaxial | GaAs GaAs | GaAlAs/GaAs/GaAlAs | Liquid Phase Epitaxy (LPE) Vapor Phase (VPE) | Ga+Al+CaAs+H2 Ga+AsH3+ PH3+CHl + H2 |

| GAP homoepitaxial | GaP | GaP (GaP; N) | Liquid Phase Epitaxy (LPE) Liquid Phase Epitaxy (LPE) | Ga+GaP+H2+(NH3) GaAs+GaP+NH3 |

| Superlattice | GaAs | GaAlAs/GaAs (lub voj voog) | Molecular Beam Epitaxy (MBE) MOCVD | Ca, As, Al GaR₃+AlR3+AsH3+H2 |

| IB homoepitaxial | InP | InP | Vapor Phase Epitaxy (VPE) Liquid Phase Epitaxy (LPE) | PCl3 + Hauv + H2 In+InAs+GaAs+InP+H₂ |

| Si/gaAs Epitaxy | Si | GaAs | Molecular Beam Epitaxy (MBE) MOGVD | Ga, As GaR₃+AsH₃+H₂ |

Post lub sij hawm: Dec-24-2024