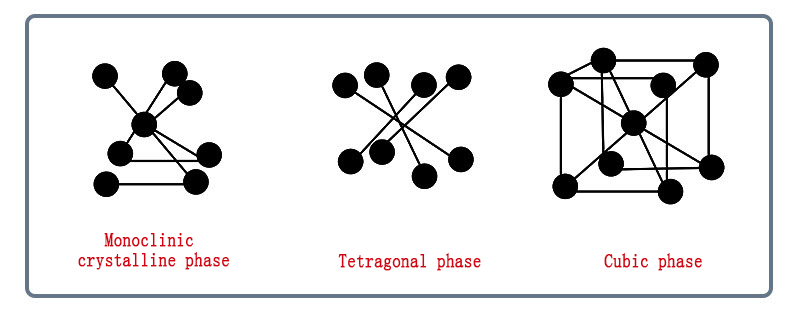

Zirconia ceramicsyog dawb, daj lossis grey thaum muaj impurities, thiab feem ntau muaj HfO2, uas tsis yooj yim rau kev sib cais. Muaj peb lub xeev crystal ntawm ntshiab ZrO2 nyob rau hauv ib txwm siab.

■Tsawg kub monoclinic (m-ZrO2)■Nruab nrab kub tetragonal (t-ZrO2)■Kub kub kub (c-ZrO2)

Cov saum toj no peb hom siv lead ua muaj nyob rau hauv qhov sib txawv ntawm qhov kub thiab txias, thiab muaj cov nram qab no kev sib hloov pauv kev sib raug zoo:

Cov yam ntxwv ntawm zirconia ceramics

High-melting-point

Zirconia melting point yog: 2715 ℃, tuaj yeem siv los ua cov khoom kub kub refractory

High hardness, zoo hnav tsis kam

Raws li Mohs hardness: sapphire >Zirconia ceramicsTsev > Khob iav > Aluminium magnesium alloy > Tempered iav > polycarbonate

Siab zog thiab toughness

Lub zog ntawm zirconia tuaj yeem ncav cuag: 1500MPa

Tsawg thermal conductivity thiab coefficient ntawm expansion

Ntawm cov khoom siv ceramic, nws cov thermal conductivity yog qis tshaj (1.6-2.03W / (mk)), thiab coefficient ntawm thermal expansion yog ze rau cov hlau.

Kev ua haujlwm hluav taws xob zoo

Lub dielectric tas li ntawm zirconia yog 3 zaug ntawm sapphire, thiab lub teeb liab yog rhiab heev.

Kev siv cov zirconia ceramics

Zirconia ceramicsyog dav siv nyob rau hauv 3C electronics, optical kev sib txuas lus, ntse hnav, biomedical, hniav nyiaj hniav kub, lub neej txhua hnub, cov ntaub ntawv refractory thiab lwm yam teb.

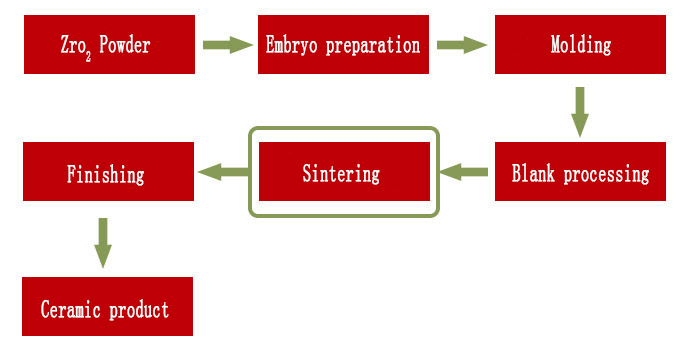

Zirconia ceramic khoom npaj technology

Sintering yog txheej txheem tseem ceeb heev hauv kev npajzirconia ceramics, qhov zoo ntawm sintering yuav cuam tshuam ncaj qha rau cov txheej txheem ceramic, tsuas yog sintering kub hloov kho kom zoo, nws lub cev embryo yuav zoo meej. Pressureless sintering yog feem ntau siv sintering txoj kev.

Vim tias cov ntaub ntawv ntshiab ceramic yog qee zaum nyuaj rau sintering, nyob rau hauv cov xwm txheej ntawm kev ua tau zoo, qee qhov sintering additives feem ntau yog qhia los ua ib feem qis melting point ntawm cov khoom tov, iav theem los yog lwm yam kua theem, los txhawb cov rearrangement hais thiab viscous flow. , thiaj li tau txais cov khoom ntom ntom, tab sis kuj txo qhov kub ntawm sintering.

Txo cov hmoov nplej kom ntau li ntau tau kuj yog ib qho tseem ceeb rau kev txhawb nqa sintering. Vim tias cov hmoov zoo dua, qhov siab dua lub zog saum npoo, qhov yooj yim rau sintering. Rau cov khoom siv ceramic thiab cov khoom lag luam nrog cov kev xav tau ua haujlwm zoo, tsis yog lub zog sintering yog qhov yooj yim tshaj plaws thiab kev lag luam sintering.

Post lub sij hawm: Lub Xya hli ntuj-24-2023