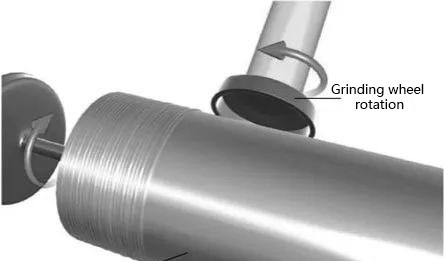

Rolling yog hais txog cov txheej txheem ntawm kev sib tsoo cov kab sab nraud ntawm silicon ib leeg siv lead ua pas nrig rau hauv ib lub pob zeb siv lead ua ntawm txoj kab uas yuav tsum tau siv lub pob zeb diamond sib tsoo log, thiab sib tsoo tawm ntawm ntug tiaj tiaj siv los yog qhov chaw ntawm ib qho siv lead ua qws.

Cov kab npoo sab nrauv ntawm ib qho siv lead ua qws npaj los ntawm ib qho siv lead ua rauv tsis du thiab tiaj tus, thiab nws txoj kab uas hla yog loj dua li txoj kab uas hla ntawm silicon wafer siv nyob rau hauv daim ntawv thov zaum kawg. Qhov xav tau tus pas nrig txoj kab uas hla tuaj yeem tau los ntawm kev dov lub taub sab nraud.

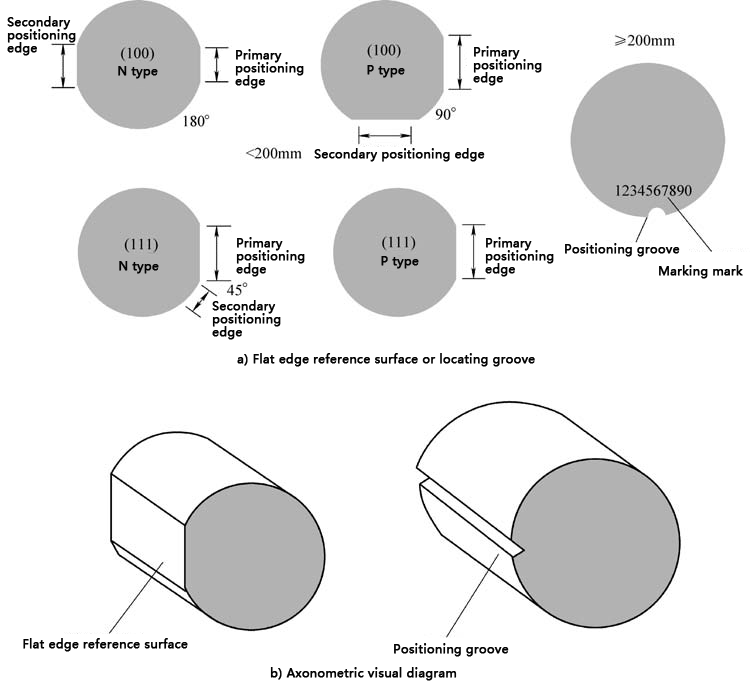

Rolling mills muaj kev ua haujlwm ntawm kev sib tsoo ntawm ntug tiaj tiaj siv los yog qhov chaw ntawm cov silicon ib leeg siv lead ua pas nrig, uas yog, ua cov kev taw qhia ntawm ib qho siv lead ua pas nrig nrog rau txoj kab uas hla. Nyob rau tib lub rolling mill khoom, lub tiaj tus ntug siv nto los yog positioning zawj ntawm ib tug siv lead ua pas nrig yog hauv av. Feem ntau, ib leeg siv lead ua pas nrig nrog txoj kab uas hla tsawg dua 200mm siv cov npoo tiaj tiaj, thiab ib qho siv lead ua rods nrog txoj kab uas hla ntawm 200mm thiab saum toj no siv qhov chaw grooves. Ib leeg siv lead ua rods nrog ib txoj kab uas hla ntawm 200mm kuj tuaj yeem ua nrog cov npoo tiaj tiaj raws li xav tau. Lub hom phiaj ntawm ib qho siv lead ua pas nrig taw qhia qhov chaw yog kom tau raws li qhov xav tau ntawm kev ua haujlwm ntawm qhov chaw ua haujlwm ntawm cov txheej txheem cov khoom siv hauv kev tsim hluav taws xob sib xyaw; los qhia txog cov qauv siv lead ua thiab kev coj ua ntawm silicon wafer, thiab lwm yam, los pab tswj kev tsim khoom; lub ntsiab positioning ntug los yog positioning zawj yog perpendicular mus rau <110> kev taw qhia. Thaum lub sij hawm ntim cov txheej txheem nti, cov txheej txheem dicing tuaj yeem ua rau lub ntuj tawg ntawm lub wafer, thiab qhov chaw tuaj yeem tiv thaiv cov tiam ntawm cov khoom tawg.

Lub hom phiaj tseem ceeb ntawm cov txheej txheem rounding muaj xws li: Txhim kho qhov zoo ntawm qhov chaw: Rounding tuaj yeem tshem tawm burrs thiab qhov tsis sib xws ntawm qhov chaw ntawm silicon wafers thiab txhim kho qhov smoothness ntawm silicon wafers, uas yog ib qho tseem ceeb heev rau cov txheej txheem photolithography thiab etching. Txo kev ntxhov siab: Kev ntxhov siab yuav raug tsim thaum lub sij hawm txiav thiab ua cov silicon wafers. Rounding tuaj yeem pab tso cov kev ntxhov siab no thiab tiv thaiv cov silicon wafers los ntawm kev tawg hauv cov txheej txheem tom ntej. Txhim kho cov neeg kho tshuab lub zog ntawm silicon wafers: Thaum lub sij hawm kev sib hloov, cov npoo ntawm silicon wafers yuav ua smoother, uas yuav pab txhim kho lub zog txhua yam ntawm silicon wafers thiab txo kev puas tsuaj thaum lub sij hawm thauj mus los thiab siv. Ua kom muaj qhov tseeb qhov tseeb: Los ntawm kev sib tw, qhov tseeb qhov tseeb ntawm silicon wafers tuaj yeem ua kom ntseeg tau, uas yog qhov tseem ceeb rau kev tsim cov khoom siv semiconductor. Txhim kho cov khoom siv hluav taws xob ntawm silicon wafers: Cov ntug ua haujlwm ntawm silicon wafers muaj qhov tseem ceeb ntawm lawv cov khoom hluav taws xob. Rounding tuaj yeem txhim kho cov khoom hluav taws xob ntawm silicon wafers, xws li txo cov xau tam sim no. Kev zoo nkauj: Cov npoo ntawm silicon wafers smoother thiab zoo nkauj dua tom qab sib dhos, uas tseem tsim nyog rau qee qhov kev thov.

Post lub sij hawm: Lub Xya hli ntuj-30-2024