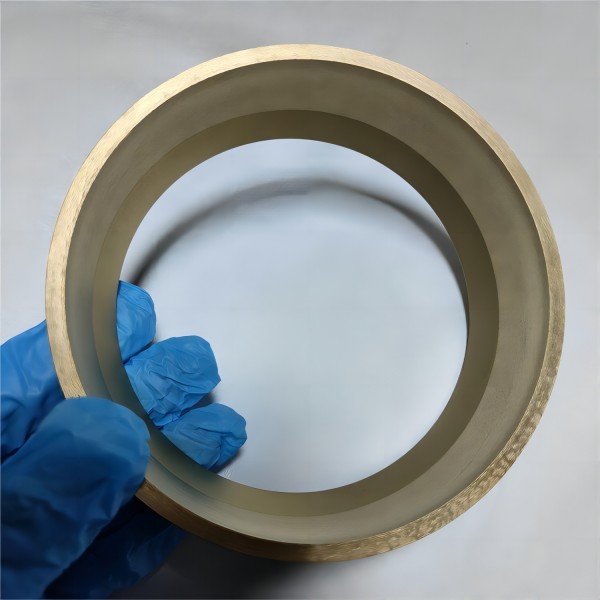

Silicon nitride bonded silicon carbide

Si3N4 bonded SiC ceramic refractory khoom, yog tov nrog siab ntshiab SIC zoo hmoov thiab Silicon hmoov, tom qab plam casting chav kawm, cov tshuaj tiv thaiv sintered nyob rau hauv 1400 ~ 1500 ° C.Thaum lub sij hawm sintering, sau lub siab ntshiab Nitrogen rau hauv lub qhov cub, ces cov silicon yuav hnov mob nrog Nitrogen thiab tsim Si3N4, Yog li Si3N4 bonded SiC cov khoom yog tsim los ntawm silicon nitride (23%) thiab silicon carbide (75%) raws li cov ntaub ntawv tseem ceeb. , sib tov nrog cov khoom siv organic, thiab zoo li tus sib tov, extrusion los yog pouring, ces ua tom qab ziab thiab nitrogenization.

Nta thiab qhov zoo:

1.High kub kam rau ua

2.High thermal conductivity thiab poob siab tsis kam

3.High mechanical zog thiab puas kuj

4.Excellent zog efficiency thiab corrosion kuj

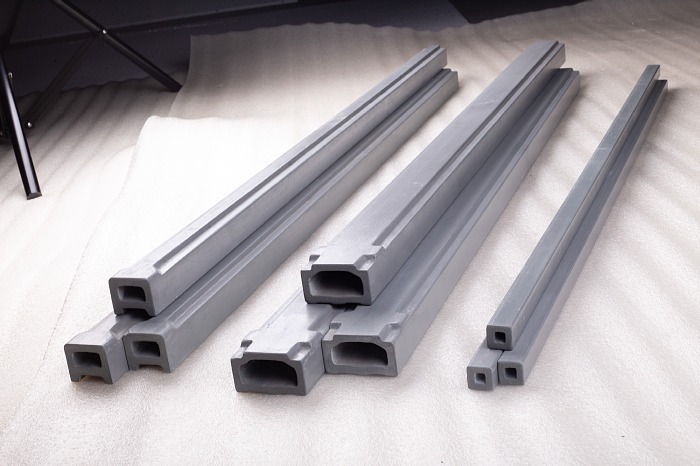

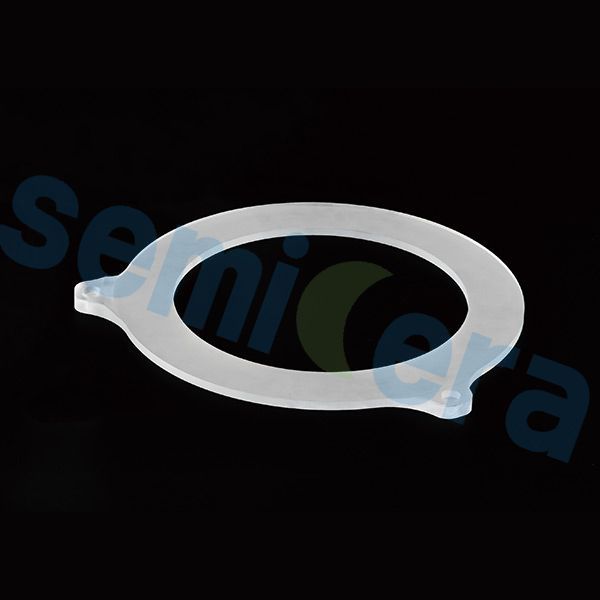

Peb muab cov khoom zoo thiab precision machined NSiC ceramic Cheebtsam uas txheej txheem los ntawm

1.Slip casting

2. Extruding

3.Uni Axial nias

4.Isostatic nias

Cov ntaub ntawv ntaub ntawv

| > Chemical Composition | Sic | 75% |

| Sib 3N4 | ≥23% | |

| Dawb Si | 0% | |

| Qhov ceev (g / cm3) | 2.70 ib~2.80 Nws | |

| Pom tseeb porosity (%) | 12~15 | |

| Khoov lub zog ntawm 20 ℃ (MPa) | 180~190 | |

| Khoov lub zog ntawm 1200 ℃ (MPa) | 207 | |

| Khoov lub zog ntawm 1350 ℃ (MPa) | 210 | |

| Compressive zog ntawm 20 ℃ (MPa) | 580 | |

| Thermal conductivity ntawm 1200 ℃ (w / mk) | 19.6 ib | |

| Thermal expansion coefficient ntawm 1200 ℃ (x 10-6 /C) | 4.70 ib | |

| Thermal shock tsis kam | Zoo heev | |

| Max.kub (℃) | 1600 | |