Tantalum carbide (TaC)yog ib tug super-siab kub resistant ceramic khoom nrog qhov zoo ntawm siab melting point, siab hardness, zoo tshuaj stability, muaj zog hluav taws xob thiab thermal conductivity, thiab lwm yam.TaC txheejtuaj yeem siv los ua ablation-resistant txheej, oxidation-resistant txheej, thiab hnav-resistant txheej, thiab yog dav siv nyob rau hauv aerospace thermal tiv thaiv, thib peb tiam semiconductor ib tug siv lead ua kev loj hlob, lub zog electronics thiab lwm yam teb.

Txheej txheem:

Tantalum carbide (TaC)yog ib hom ultra-siab kub resistant ceramic khoom nrog qhov zoo ntawm qhov siab melting point, siab hardness, zoo tshuaj stability, muaj zog hluav taws xob thiab thermal conductivity. Yog li ntawd,TaC txheejtuaj yeem siv los ua ablation-resistant txheej, oxidation-resistant txheej, thiab hnav-resistant txheej, thiab yog dav siv nyob rau hauv aerospace thermal tiv thaiv, thib peb tiam semiconductor ib tug siv lead ua kev loj hlob, lub zog electronics thiab lwm yam teb.

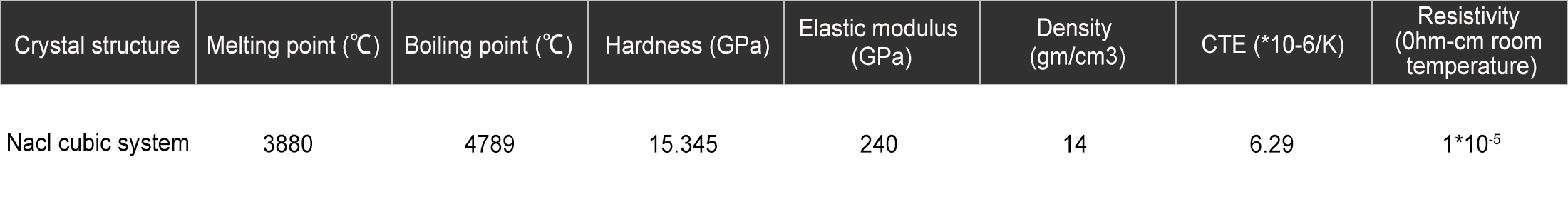

Intrinsic characterization ntawm coatings:

Peb siv txoj kev slurry-sintering los npajTAC coatingsntawm txawv thicknesses ntawm graphite substrates ntawm ntau qhov ntau thiab tsawg. Ua ntej, high-purity hmoov uas muaj Ta qhov thiab C qhov chaw yog configured nrog dispersant thiab binder los ua ib tug uniform thiab ruaj khov precursor slurry. Nyob rau tib lub sij hawm, raws li qhov loj ntawm graphite qhov chaw thiab cov thickness yuav tsum tauTaC txheej, pre-coating yog npaj los ntawm kev txau, nchuav, infiltration thiab lwm yam ntaub ntawv. Thaum kawg, nws yog rhuab mus rau saum toj 2200 ℃ nyob rau hauv lub tshuab nqus tsev ib puag ncig los npaj ib tug uniform, ntom, ib theem, thiab zoo-crystalline.TaC txheej.

Intrinsic characterization ntawm coatings:

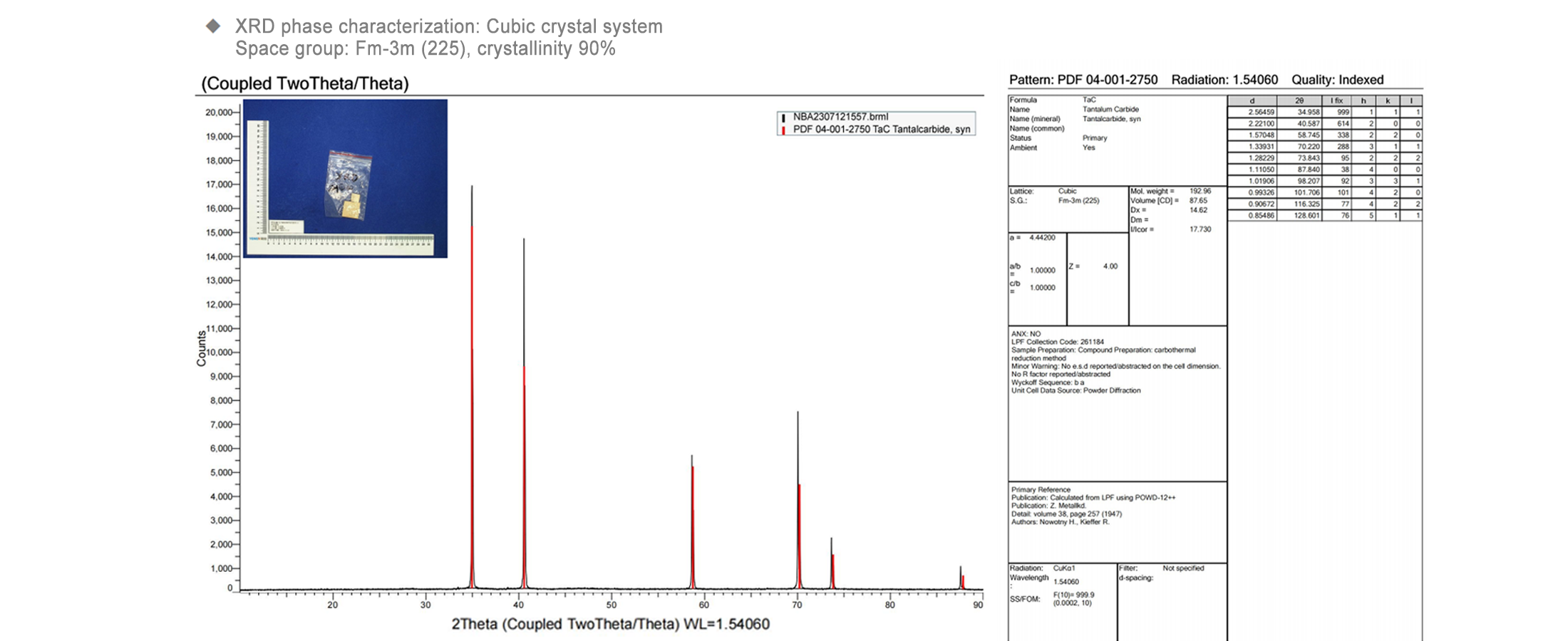

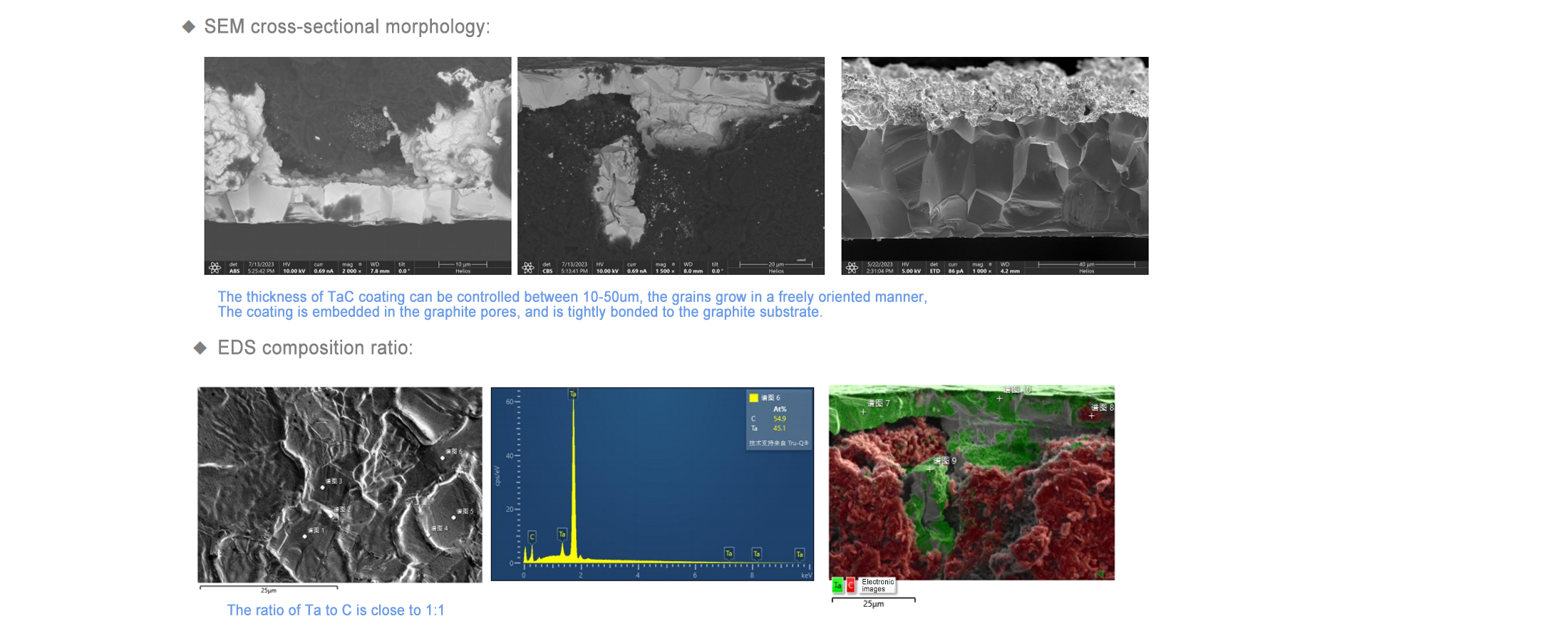

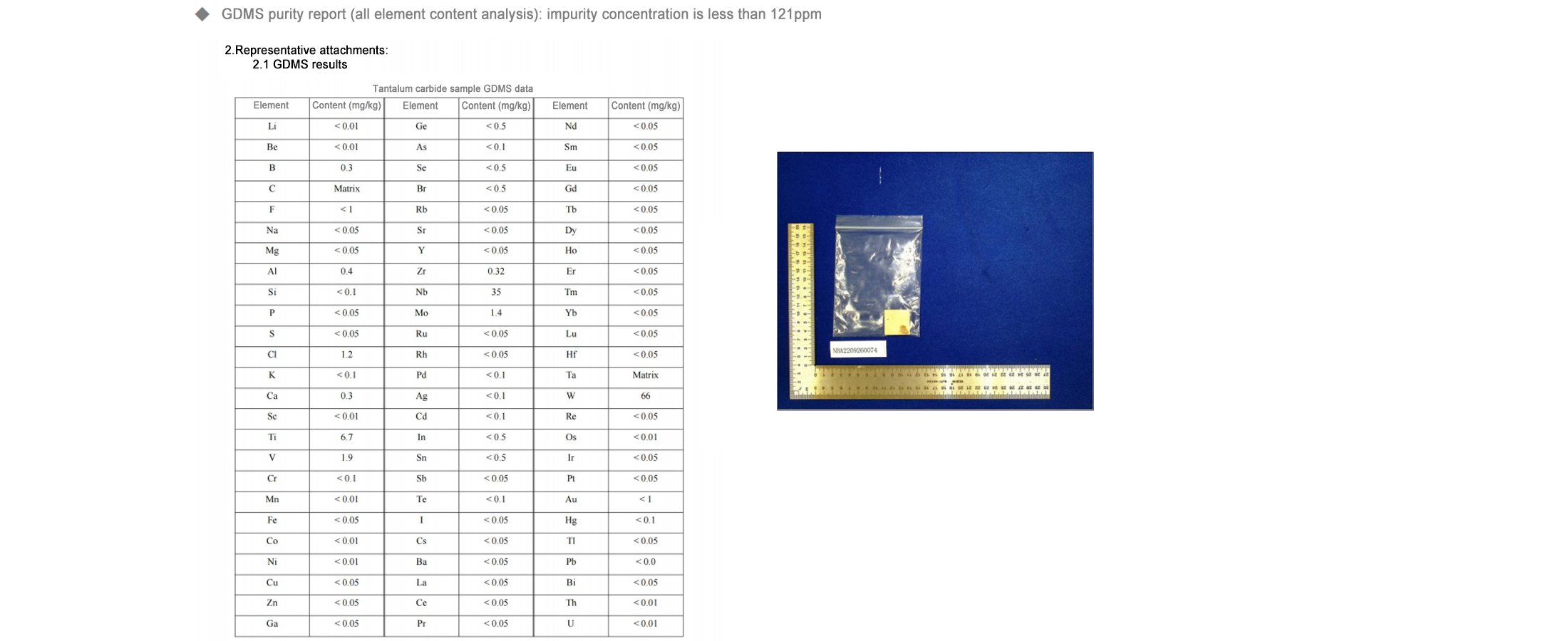

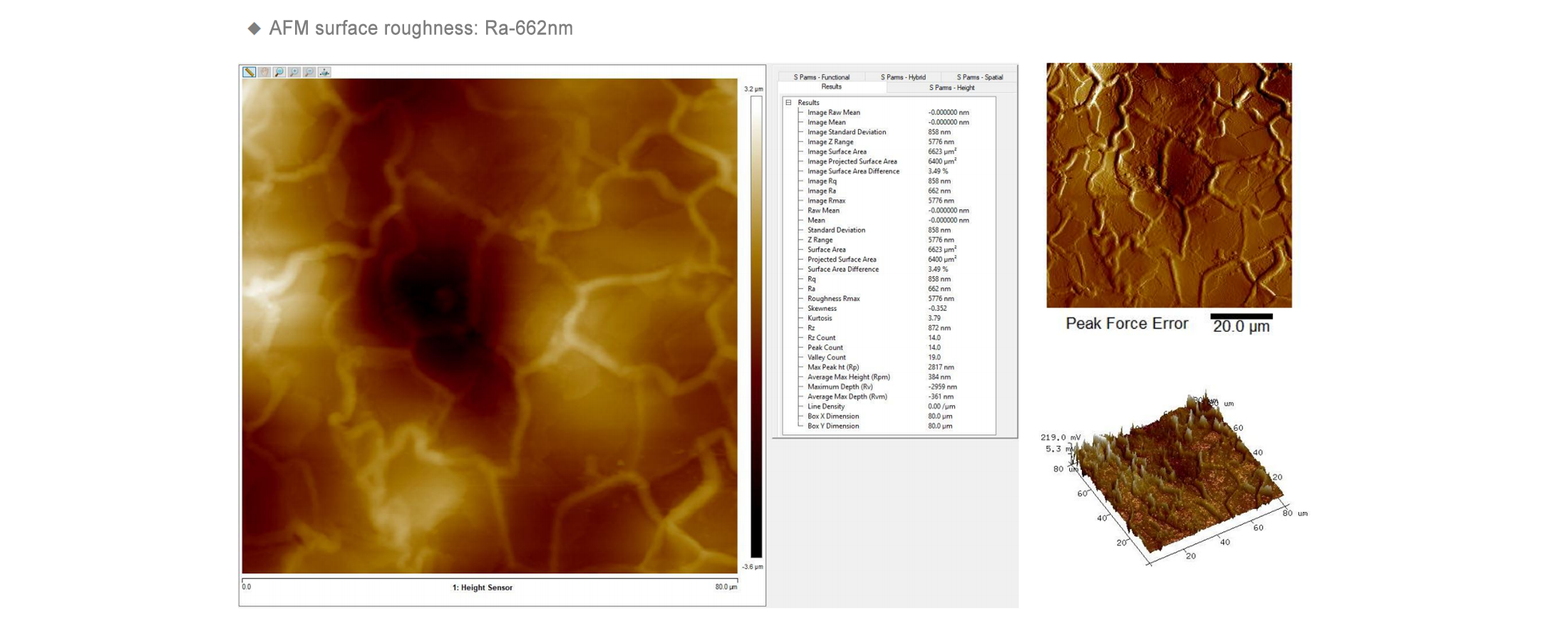

Lub thickness ntawmTaC txheejyog hais txog 10-50 μm, cov nplej loj hlob nyob rau hauv ib qho kev taw qhia dawb, thiab nws yog tsim los ntawm TaC nrog ib lub ntsej muag-centered cubic qauv, tsis muaj lwm yam impurities; cov txheej yog ntom, cov qauv ua tiav, thiab crystallinity siab.TaC txheejtuaj yeem sau cov pores rau ntawm qhov chaw ntawm graphite, thiab nws yog chemically bonded rau graphite matrix nrog siab sib txuas lub zog. Qhov piv ntawm Ta mus rau C hauv txheej yog ze rau 1: 1. GDMS purity detection reference standard ASTM F1593, qhov impurity concentration yog tsawg dua 121ppm. Tus lej ntsuas qhov sib txawv (Ra) ntawm txheej txheej profile yog 662nm.

Kev siv dav dav:

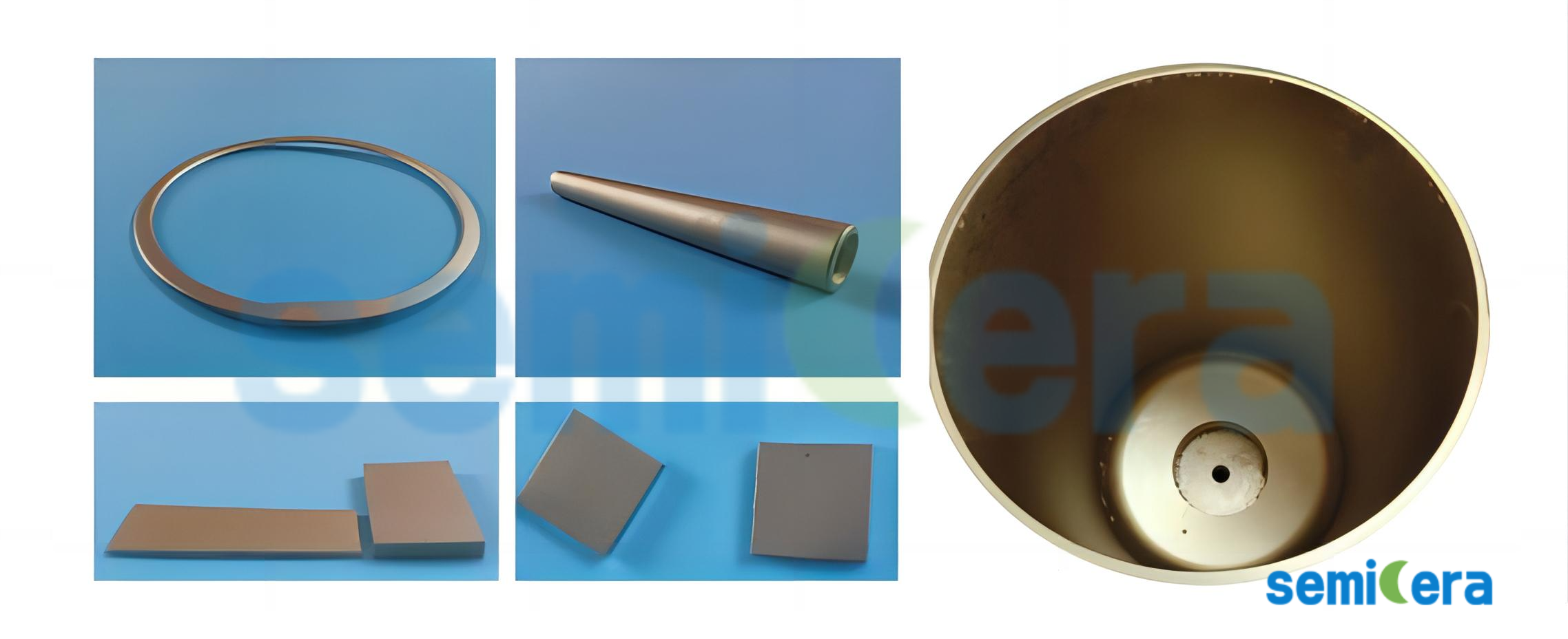

GaN thiabSiC epitaxialCVD reactor Cheebtsam, suav nrog wafer nqa, satellite tais diav, da dej hau, npog sab saum toj thiab susceptors.

SiC, GaN thiab AlN siv lead ua kev loj hlob Cheebtsam, suav nrog crucibles, noob siv lead ua tuav, ntws qhia thiab lim.

Cov khoom lag luam, suav nrog cov khoom siv cua sov, cov nozzles, cov nplhaib tiv thaiv thiab cov khoom siv brazing.

Cov yam ntxwv tseem ceeb:

Kub kub stability ntawm 2600 ℃

Muab kev tiv thaiv tsis tu ncua hauv cov tshuaj lom neeg hnyav ntawm H2, NH3, SiH4and Si vapor

Haum rau kev tsim khoom loj nrog cov voj voog luv luv.