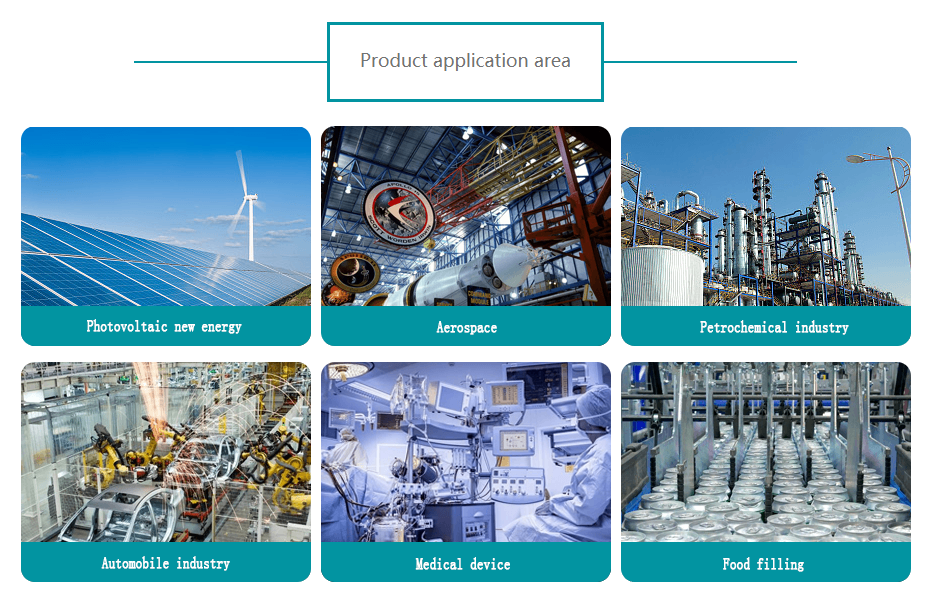

Tau txais kev txaus siab ntawm cov neeg yuav khoom yog peb lub tuam txhab lub hom phiaj nyob mus ib txhis. Peb yuav ua kom zoo tshaj plaws los tsim cov khoom tshiab thiab zoo tshaj plaws, ua kom txaus siab rau koj cov kev xav tau tshwj xeeb thiab muab rau koj nrog kev muag khoom ua ntej, ntawm-muag thiab tom qab-muag khoom thiab cov kev pab cuam rau tus nqi pheej yig Hoobkas Nqe Kev Cai Muaj Ceramic Robotic Arm rau Semiconductor Daim Ntawv Thov, Peb lub koom haum tau mob siab rau qhov "cov neeg siv khoom ua ntej" thiab cog lus los pab cov neeg siv khoom nthuav dav lawv cov lag luam me, kom lawv dhau los ua Tus Thawj Coj Loj !

Tau txais kev txaus siab ntawm cov neeg yuav khoom yog peb lub tuam txhab lub hom phiaj nyob mus ib txhis. Peb yuav ua haujlwm zoo los tsim cov khoom tshiab thiab zoo tshaj plaws, ua kom txaus siab rau koj cov kev xav tau tshwj xeeb thiab muab koj cov khoom muag ua ntej, muag thiab tom qab muag thiab cov kev pabcuam rau koj.Tuam Tshoj Ceramic thiab Ceramic Robotic Arm, Peb qhov zoo yog peb qhov kev tsim kho tshiab, hloov tau yooj yim thiab kev ntseeg siab uas tau tsim nyob rau hauv 20 xyoo dhau los. Peb tsom mus rau kev muab kev pabcuam rau peb cov neeg siv khoom raws li lub hauv paus tseem ceeb hauv kev ntxiv dag zog rau peb txoj kev sib raug zoo mus ntev. Qhov tsis tu ncua ntawm cov khoom lag luam qib siab ua ke nrog peb cov kev pabcuam ua ntej thiab tom qab muag zoo ua kom muaj kev sib tw muaj zog hauv kev lag luam thoob ntiaj teb.

Zirconia yog ib yam khoom uas muaj zog txhua yam thiab tawg toughness ntawm chav tsev kub. Peb zirconia (ZrO2) ntxiv nrog 3mol% Y2O3 ib nrab ruaj khov zirconia (PSZ). Vim hais tias cov particle txoj kab uas hla ntawm PSZ cov khoom yog me me, nws muaj peev xwm ua tiav nrog high precision, thiab nws daim ntawv thov nyob rau hauv precision machining qhov chaw xws li pwm yog expanding. Tsis tas li ntawd, kuj tuaj yeem siv rau kev lag luam cov cuab yeej, kho qhov muag connector qhov chaw thiab crushing khoom nruab nrab. Lub siab tawg toughness ntawm PSZ yuav siv tau los ua tshwj xeeb springs, thiab nws kuj yog lug siv nyob rau hauv domestic ceramic riam, slicer thiab lwm yam.

Khoom Khoom

| Yam khoom | 95% Alumina | 99% Alumina | Zirconia | Silicon carbide | Silicon Nitride | Aluminium Nitride | Machinable ceramic |

| Xim | dawb | Lub teeb daj | dawb | dub | dub | grey | dawb |

| Qhov ceev (g / cm3) | 3.7g / cm3 | 3.9g / cm3 | 6.02 g / cm3 | 3.2g / cm3 | 3.25g / cm3 | 3.2g / cm3 | 2.48g / cm3 |

| Kev nqus dej | 0% | 0% | 0% | 0% | 0% | 0% | 0% |

| Hardness (HV) | 23.7 ib | 23.7 ib | 16.5 ib | 33 | 20 | - | - |

| Flexural zog (MPa) | 300MPa | 400MPa | 1100MPa | 450MPa | 800MPa | 310 MPa | 91mpa ua |

| Compressive zog (MPa) | 2500MPa | 2800MPa | 3600MPa | 2000MPa | 2600 MPa | - | 340 MPa |

| Young's Modulus Ntawm Elasticity | 300 GP ua | 300 GP ua | 320 GP ua | 450 GP ua | 290 gp ua | 310 ~ 350 GPa | 65gp ua |

| Poisson tus ratio | 0.23 | 0.23 | 0.25 | 0.14 ib | 0.24 ib | 0.24 ib | 0.29 ib |

| Thermal conductivity | 20 W / m ° C | 32 W / m ° C | 3 W / m ° C | 50 W / m ° C | 25 W / m ° C | 150 W / m ° C | 1.46 W / m ° C |

| Dielectric zog | 14KV / hli | 14KV / hli | 14KV / hli | 14KV / hli | 14KV / hli | 14KV / hli | 14KV / hli |

| Volume Resistivity (25 ℃) | > 1014Ω·cm | > 1014Ω·cm | > 1014Ω·cm | > 105Ω·cm | > 1014Ω·cm | > 1014Ω·cm | > 1014Ω·cm |

Zirconia (ZrO2) Kuv siv lub ntsiab

Pwm thiab pwm cov cuab yeej (ntau yam pwm, precision positioning fixture, rwb thaiv tsev fixture); Mill qhov chaw (classifier, cua ntws zeb, hlaws zeb); Cov cuab yeej muaj (kev lag luam cutter, slitter tshuab, ca xovxwm yob); Optical connector Cheebtsam (lub nplhaib sealing, lub tes tsho, V-groove fixture); Caij nplooj ntoos hlav tshwj xeeb (coil caij nplooj ntoos hlav, phaj caij nplooj ntoos hlav); Cov khoom siv (me me insulated screwdriver, ceramic riam, slicer).

Tau txais kev txaus siab ntawm cov neeg yuav khoom yog peb lub tuam txhab lub hom phiaj nyob mus ib txhis. Peb yuav ua kom zoo tshaj plaws los tsim cov khoom tshiab thiab zoo tshaj plaws, ua kom txaus siab rau koj cov kev xav tau tshwj xeeb thiab muab rau koj nrog kev muag khoom ua ntej, ntawm-muag thiab tom qab-muag khoom thiab cov kev pab cuam rau tus nqi pheej yig Hoobkas Nqe Kev Cai Muaj Ceramic Robotic Arm rau Semiconductor Daim Ntawv Thov, Peb lub koom haum tau mob siab rau qhov "cov neeg siv khoom ua ntej" thiab cog lus los pab cov neeg siv khoom nthuav dav lawv cov lag luam me, kom lawv dhau los ua Tus Thawj Coj Loj !

Tus nqi pheej yigTuam Tshoj Ceramic thiab Ceramic Robotic Arm, Peb qhov zoo yog peb qhov kev tsim kho tshiab, hloov tau yooj yim thiab kev ntseeg siab uas tau tsim nyob rau hauv 20 xyoo dhau los. Peb tsom mus rau kev muab kev pabcuam rau peb cov neeg siv khoom raws li lub hauv paus tseem ceeb hauv kev ntxiv dag zog rau peb txoj kev sib raug zoo mus ntev. Qhov tsis tu ncua ntawm cov khoom lag luam qib siab ua ke nrog peb cov kev pabcuam ua ntej thiab tom qab muag zoo ua kom muaj kev sib tw muaj zog hauv kev lag luam thoob ntiaj teb.

-

100% Original Anti-shock Silicon Carbide Cyclon...

-

Silicon carbide wafer sib tsoo disk, Ras0.2um

-

Cov Khoom Tshiab Kub Kub Thermal Sintering High Strengt ...

-

Tuam Tshoj Cov Khoom Tshiab Silicon Carbide Sic Industria ...

-

Cov Khoom Kub Tshiab Khoom Siv Hnav-Resistant Silicon ...

-

Tus nqi zoo tshaj ntawm Bidirectional Ob Lub Taub Hau Silicon...