Hauv ob peb xyoos dhau los, peb lub tuam txhab tau nqus thiab zom cov thev naus laus zis sib txawv hauv tsev thiab txawv teb chaws. Meanwhile, peb cov neeg ua haujlwm ua lag luam ib pab pawg kws tshaj lij tau mob siab rau kev loj hlob ntawm Tuam Tshoj Chaw tsim tshuaj paus rau High Corrosion Resisting Ssic Shaft Tsho rau Twj Silicon Carbide Lub Tes Tsho , Peb nquag txais tos cov neeg yuav khoom tshiab thiab qub muab peb cov lus qhia thiab cov lus pom zoo rau kev koom tes, cia peb paub tab thiab tsim ib leeg ib leeg, kuj ua rau peb cov zej zog thiab cov neeg ua haujlwm!

Hauv ob peb xyoos dhau los, peb lub tuam txhab tau nqus thiab zom cov thev naus laus zis sib txawv hauv tsev thiab txawv teb chaws. Lub caij no, peb cov neeg ua haujlwm ua lag luam ib pab pawg kws tshaj lij tau mob siab rau kev loj hlob ntawmTuam Tshoj Silicon Carbide Ceramic Foob Nplhaib thiab Silicon Carbide, Peb muaj ntau tshaj li 8 xyoo ntawm kev paub nyob rau hauv no kev lag luam thiab muaj ib tug zoo lub koob npe nrov nyob rau hauv daim teb no. Peb cov kev daws teeb meem tau txais kev qhuas los ntawm cov neeg siv khoom thoob ntiaj teb. Peb lub hom phiaj yog los pab cov neeg siv khoom paub lawv lub hom phiaj. Peb tab tom ua haujlwm zoo los ua kom tiav qhov xwm txheej yeej-yeej thiab zoo siab tos txais koj tuaj koom nrog peb.

Siliconized graphite yog cov khoom sib xyaw uas silicon carbide txuas rau saum npoo ntawm graphite substrate. Nws muaj cov yam ntxwv ntawm siab hardness, siab mechanical zog thiab hnav tsis kam ntawm silicon carbide, nrog rau nws tus kheej-lubricating zog thiab thermal shock kuj ntawm graphite. Nws yog ib qho zoo tagnrho cov ntaub ntawv sib txhuam thiab cov khoom siv foob, haum rau kev sib khi ntawm ntau yam twj tso kua mis, roj twj, tshuaj twj, thiab bearings ntawm ntau yam high-ceev thiab high-load lub ntsiab twj. Tsis tas li ntawd, siliconized graphite muaj qhov zoo oxidation tsis kam, thermal poob siab tsis kam, porosity tsawg, thiab qee yam hluav taws xob conductivity, thiab tuaj yeem siv los ua cov ntaub ntawv xws li hlau smelting crucibles thiab cov hlab ntsha.

Cov muaj pes tsawg leeg ntawm siliconized graphite yog ib yam, qhov saum npoo yog zoo ib yam nrog rau sab hauv, thiab muaj pes tsawg leeg ntawm silicon carbide thiab graphite yog adjustable. Qhov siab dua cov ntsiab lus ntawm silicon carbide, qhov ntau dua qhov ntom ntawm cov khoom, qhov siab dua lub zog compressive, thiab cov resistivity nce.

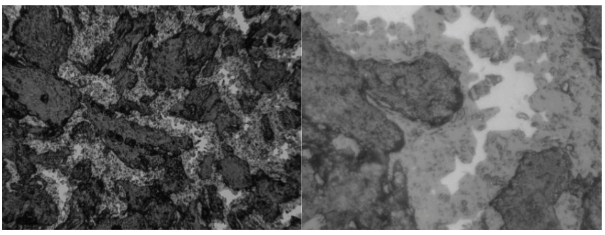

Metallographic duab ntawm siliconized graphite

(qhov dub yog graphite, qhov grey yog silicon carbide, thiab qhov dawb yog silicon)

| 硅化石墨主要技术指标 | |

| 类别 Yam khoom | 指标 Tus nqi |

| 密度 Ceev | 2.4-2.9g / cm³ |

| Cov porosity | <0.5% |

| 抗压强度 Compressive zog | > 400MPa |

| Flexural zog Flexural zog | > 120MPa |

| Thermal conductivity | 120 W/mK |

| Thermal expansion coefficient | 4.5 × 10-6 |

| Elastic modulus | 120 GP ua |

| 冲击强度 Impact zog | 1.9 KJ/m² |

| Dej lubricated kev sib txhuam | 0.005 ib |

| Kev sib txhuam coefficient ntawm qhuav qhuav | 0.05 Nws |

| 化学稳定性 Tshuaj stability | 各种盐,有机溶剂,强酸(HF, HCl, H₂SO)4HNO ₃) Ntau cov ntsev, cov kuab tshuaj organic, muaj zog acids (HF, HCl, H₂SO4HNO ₃) |

| 长期稳定使用温度 Lub sij hawm ntev ruaj khov siv kub | 800 ℃ (氧化气氛), 2300 ℃ (惰性或真空气氛) 800 ℃ (oxidizing cua), 2300 ℃ (inert lossis nqus cua) |

| Hluav taws xob resistivity | 120 × 10-6Ωm |

Hauv ob peb xyoos dhau los, peb lub tuam txhab tau nqus thiab zom cov thev naus laus zis sib txawv hauv tsev thiab txawv teb chaws. Meanwhile, peb cov neeg ua haujlwm ua lag luam ib pab pawg kws tshaj lij tau mob siab rau kev loj hlob ntawm Tuam Tshoj Chaw tsim tshuaj paus rau High Corrosion Resisting Ssic Shaft Tsho rau Twj Silicon Carbide Lub Tes Tsho , Peb nquag txais tos cov neeg yuav khoom tshiab thiab qub muab peb cov lus qhia thiab cov lus pom zoo rau kev koom tes, cia peb paub tab thiab tsim ib leeg ib leeg, kuj ua rau peb cov zej zog thiab cov neeg ua haujlwm!

Tuam Tshoj Chaw tsim tshuaj paus rauTuam Tshoj Silicon Carbide Ceramic Foob Nplhaib thiab Silicon Carbide, Peb muaj ntau tshaj li 8 xyoo ntawm kev paub nyob rau hauv no kev lag luam thiab muaj ib tug zoo lub koob npe nrov nyob rau hauv daim teb no. Peb cov kev daws teeb meem tau txais kev qhuas los ntawm cov neeg siv khoom thoob ntiaj teb. Peb lub hom phiaj yog los pab cov neeg siv khoom paub lawv lub hom phiaj. Peb tab tom ua haujlwm zoo los ua kom tiav qhov xwm txheej yeej-yeej thiab zoo siab tos txais koj tuaj koom nrog peb.

-

Qhov zoo tshaj plaws-muag Refractory Materials-High Temperat ...

-

Factory Supply Silicon Carbide Sic Industrial S...

-

Hoobkas Rau Refractory Slab Ceramic Silicon Tsheb ...

-

High definition Graphite Felt Carbon Graphite R...

-

Hauv qab nqe Hoobkas Nqe Kev Cai Muaj Ce ...

-

Kub muag rau Industrial Rauv Sic Electric Nws ...