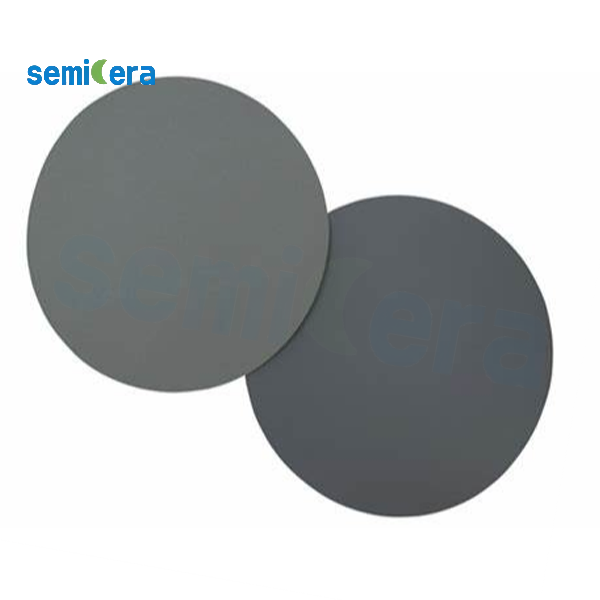

Peb tuaj yeem muab kev ruaj ntseg thiab txhim khu kev qhasilicon carbide siv lead ua nkoj, silicon carbide paddles, silicon carbide rauv tubesrau 4 nti mus rau 6 nti semiconductor wafer kev lag luam. Lub purity tuaj yeem ncav cuag 99.9% yam tsis muaj kuab paug rau wafer.

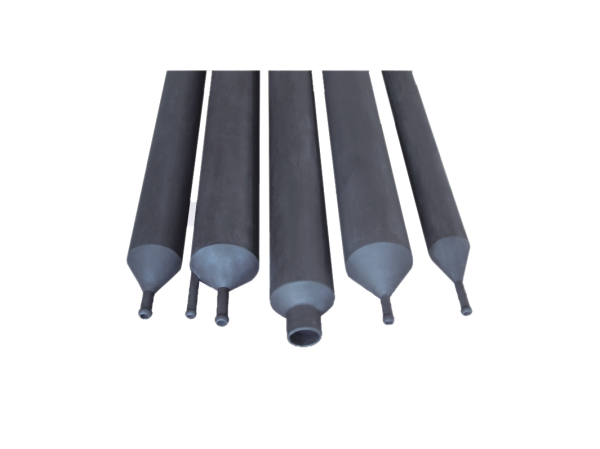

Silicon carbide rauv tubeyog siv rau: 4-6 nti silicon wafer LTO = silica, SIPOS = oxy-polysilicon, SI3N4 = silicon nitride, PSG = phosphosilicon iav, POLY = polysilicon zaj duab xis loj hlob.Nws yog cov khoom siv roj (lossis cov kua dej gasification) ua los ntawm thermal zog los ua kom muaj cov yeeb yaj kiab ntawm cov khoom siv ntawm cov substrate. Tsawg siab tshuaj vapor deposition yog nqa tawm ntawm lub siab tsis tshua muaj siab, vim qhov tsis tshua muaj siab, qhov nruab nrab txoj kev pub dawb ntawm cov pa roj molecules yog loj, yog li ntawd lub uniformity ntawm zus tau tej cov zaj duab xis yog zoo, thiab lub substrate yuav vertically muab tso rau thiab cov nqi ntawm cov khoom. loading yog loj, tshwj xeeb tshaj yog haum rau loj-scale integrated circuits, discrete pab kiag li lawm, hwj chim electronics, optoelectronic li thiab optical fiber thiab lwm yam kev lag luam ntawm industrial ntau lawm khoom tshwj xeeb.

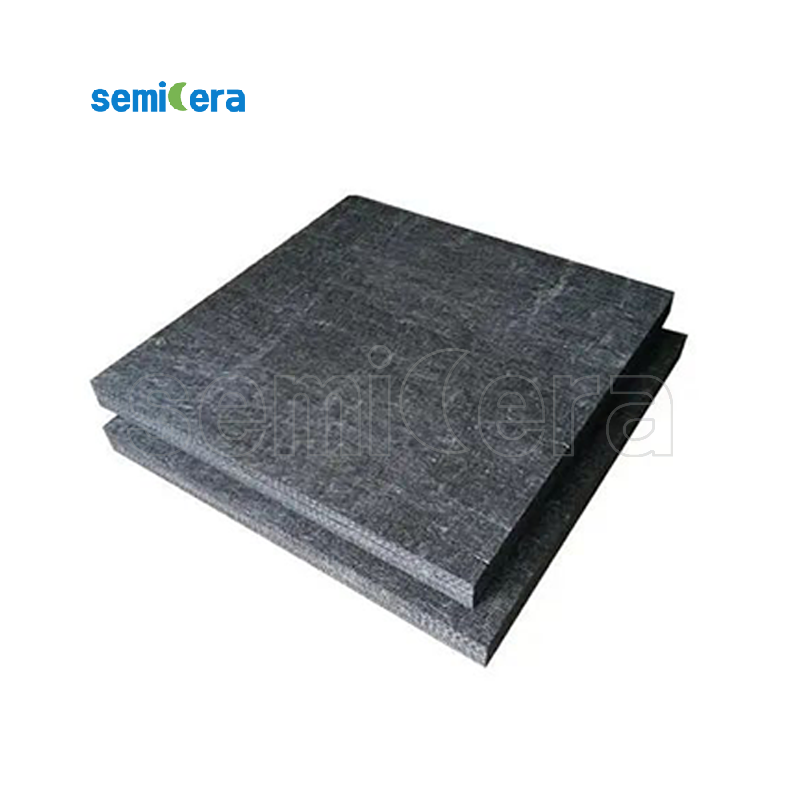

Semicera Energy Technology Co., Ltd yog cov kws tshaj lij kev tshawb fawb, kev tsim kho, tsim khoom thiab muag khoom ntawm silicon carbide ceramic khoom. Txij li thaum nws tsim nyob rau hauv 2016, Semicera Zog tau mastered isostatic nias molding txheej txheem, txhiab nias molding txheej txheem, grouting molding txheej txheem thiab nqus extrusion molding txheej txheem. Peb lub tuam txhab siv 6 silicon carbide ceramic sintering ntau lawm kab, muaj 8 CNC, 6 precision sib tsoo tshuab, kuj tuaj yeem muab koj cov khoom siv silicon carbide ceramic sintered, tab sis kuj tuaj yeem muab silicon carbide ceramics, alumina ceramics, aluminium nitride ceramics, zirconia ceramics ua cov kev pabcuam. .