Hauv cov txheej txheem tsim khoom semiconductor,etchingthev naus laus zis yog txheej txheem tseem ceeb uas yog siv los tshem tawm cov ntaub ntawv tsis xav tau ntawm lub substrate los tsim cov qauv hauv Circuit Court complex. Kab lus no yuav qhia txog ob lub ntsiab lus etching thev naus laus zis hauv kev nthuav dav - capacitively coupled plasma etching (CCP) thiab inductively coupled plasma etching (ICP), thiab tshawb nrhiav lawv cov ntawv thov hauv kev sib txawv cov ntaub ntawv.

Capacitively coupled plasma etching (CCP)

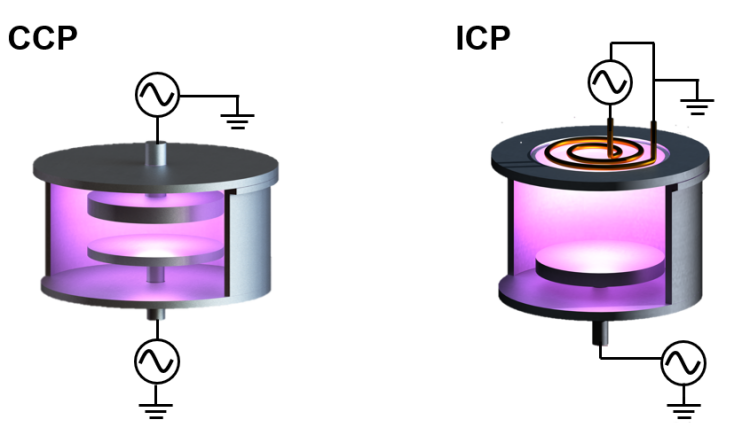

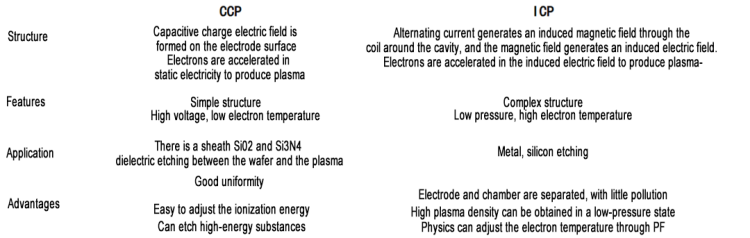

Capacitively coupled plasma etching (CCP) yog ua tiav los ntawm kev siv ib qho hluav taws xob RF rau ob qho tib si phaj electrodes los ntawm tus matcher thiab DC thaiv capacitor. Ob lub electrodes thiab plasma ua ke ua ib qho sib npaug capacitor. Nyob rau hauv cov txheej txheem no, lub RF voltage tsim ib tug capacitive sheath nyob ze ntawm lub electrode, thiab ciam teb ntawm lub sheath hloov nrog lub ceev oscillation ntawm lub voltage. Thaum cov electrons ncav cuag qhov hloov pauv sai sai, lawv raug cuam tshuam thiab nce lub zog, uas ua rau muaj kev sib cais lossis ionization ntawm cov roj molecules los tsim cov ntshav. CCP etching feem ntau yog siv rau cov ntaub ntawv uas muaj cov khoom siv hluav taws xob ntau dua, xws li dielectrics, tab sis vim nws qhov qis qis qis, nws yog qhov tsim nyog rau cov ntawv thov uas xav tau kev tswj kom zoo.

Inductively coupled plasma etching (ICP)

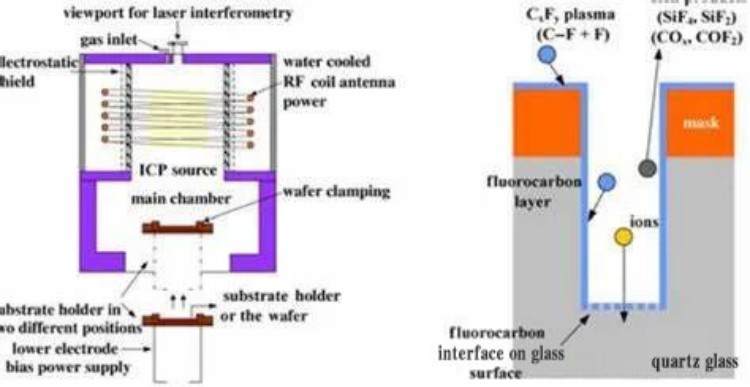

Inductively ua ke plasmaetching(ICP) yog ua raws li lub hauv paus ntsiab lus uas qhov hloov pauv tam sim no dhau los ntawm lub kauj los tsim kom muaj qhov sib nqus sib nqus. Nyob rau hauv qhov kev txiav txim ntawm no magnetic teb, cov electrons nyob rau hauv cov tshuaj tiv thaiv chamber yog ceev thiab txuas ntxiv mus ceev nyob rau hauv induced hluav taws xob teb, nws thiaj li sib tsoo nrog cov tshuaj tiv thaiv roj molecules, ua rau cov molecules dissociate los yog ionize thiab tsim plasma. Cov qauv no tuaj yeem tsim cov nqi ntshav siab thiab tso cai rau lub plasma ntom ntom thiab pob hluav taws xob ua kom haum rau nws tus kheej, uas ua rauICP etchingzoo heev rau etching cov ntaub ntawv uas tsis tshua muaj chemical bond zog, xws li silicon thiab hlau. Tsis tas li ntawd, ICP thev naus laus zis kuj tseem muab qhov zoo sib xws thiab kev sib tw.

1. Hlau etching

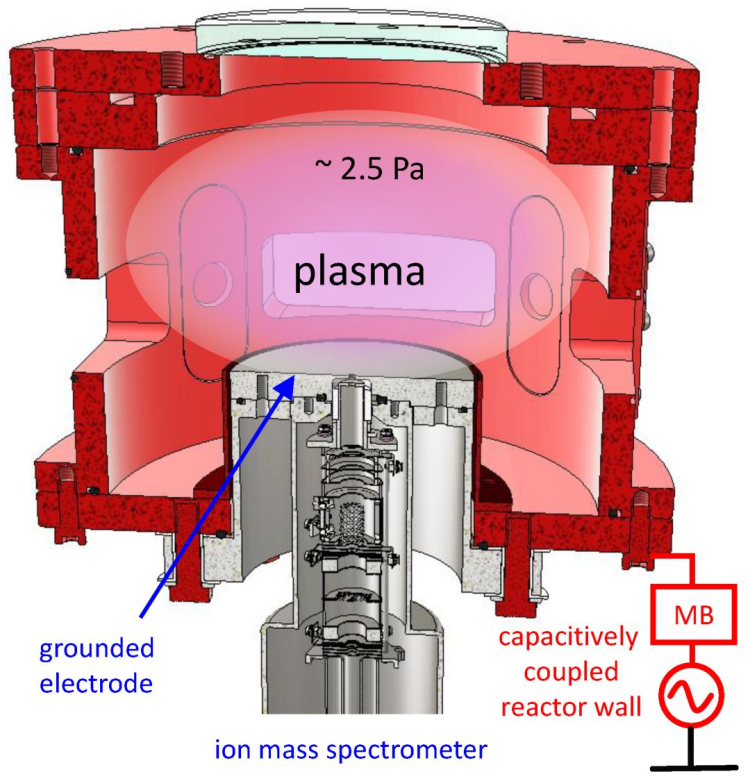

Hlau etching feem ntau yog siv rau kev ua haujlwm ntawm kev sib tshuam thiab ntau txheej hlau thaiv. Nws cov kev cai muaj xws li: siab etching tus nqi, siab xaiv (ntau dua 4: 1 rau lub npog ntsej muag thiab ntau dua 20: 1 rau interlayer dielectric), siab etching uniformity, zoo tswj qhov loj me, tsis muaj plasma puas, tsis tshua muaj paug paug, thiab tsis muaj corrosion rau hlau. Hlau etching feem ntau yog siv inductively txuas nrog plasma etching khoom.

•Aluminium etching: Aluminium yog cov khoom siv tseem ceeb tshaj plaws nyob rau hauv nruab nrab thiab tom qab theem ntawm kev tsim cov nti, nrog rau qhov zoo ntawm qhov tsis muaj zog, yooj yim deposition thiab etching. Aluminium etching feem ntau yog siv cov ntshav los ntawm cov roj chloride (xws li Cl2). Aluminium reacts nrog chlorine los tsim volatile aluminium chloride (AlCl3). Tsis tas li ntawd, lwm yam halides xws li SiCl4, BCl3, BBr3, CCl4, CHF3, thiab lwm yam tuaj yeem muab ntxiv kom tshem tawm cov oxide txheej ntawm cov txhuas saum npoo los xyuas kom meej qhov zoo li qub.

• Tungsten etching: Nyob rau hauv ntau txheej hlau hlau sib txuas cov qauv, tungsten yog cov hlau tseem ceeb siv rau nruab nrab ntu kev sib txuas ntawm cov nti. fluorine-based lossis chlorine-based gases tuaj yeem siv los ua cov hlau tungsten, tab sis cov roj fluorine-based gases muaj kev xaiv tsis zoo rau silicon oxide, thaum chlorine-based gases (xws li CCl4) muaj kev xaiv zoo dua. Nitrogen feem ntau yog ntxiv rau cov tshuaj tiv thaiv roj kom tau txais qhov siab etching kua nplaum xaiv, thiab oxygen ntxiv los txo cov pa roj carbon deposition. Etching tungsten nrog cov roj chlorine tuaj yeem ua tiav anisotropic etching thiab siab xaiv. Cov pa roj siv rau hauv qhuav etching ntawm tungsten feem ntau yog SF6, Ar thiab O2, uas SF6 tuaj yeem decomposed hauv plasma los muab cov tshuaj fluorine atoms thiab tungsten rau cov tshuaj tiv thaiv los tsim cov tshuaj fluoride.

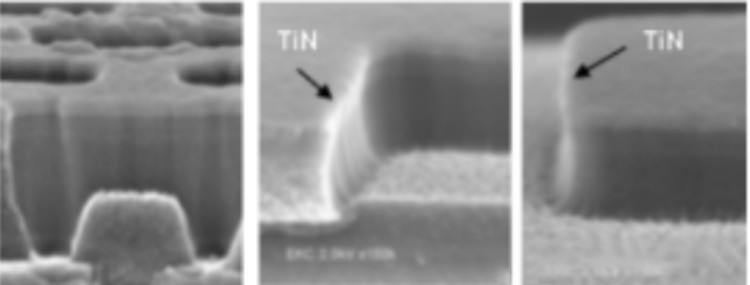

• Titanium nitride etching: Titanium nitride, raws li cov khoom siv npog ntsej muag tawv, hloov cov tshuaj silicon nitride lossis oxide daim npog ntsej muag hauv cov txheej txheem dual damascene. Titanium nitride etching feem ntau yog siv rau hauv cov txheej txheem qhib lub ntsej muag nyuaj, thiab cov khoom siv tshuaj tiv thaiv tseem ceeb yog TiCl4. Kev xaiv ntawm lub ntsej muag ib txwm siv thiab cov txheej txheem qis-k dielectric tsis siab, uas yuav ua rau cov tsos ntawm arc-shaped profile nyob rau sab saum toj ntawm qis-k dielectric txheej thiab nthuav dav ntawm qhov zawj dav tom qab etching. Qhov sib nrug ntawm cov kab hlau tso tawm me me dhau lawm, uas yog qhov yooj yim rau kev sib tsoo los yog kev tawg ncaj qha.

2. Insulator etching

Cov khoom ntawm insulator etching feem ntau yog cov khoom siv hluav taws xob xws li silicon dioxide lossis silicon nitride, uas tau siv dav los tsim cov qhov sib tiv tauj thiab cov qhov txuas txuas rau cov txheej txheem sib txawv. Dielectric etching feem ntau yog siv etcher raws li lub hauv paus ntsiab lus ntawm capacitively coupled plasma etching.

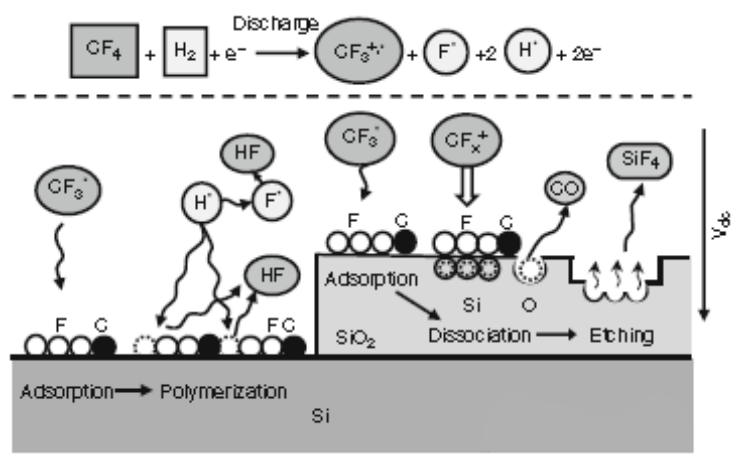

• Plasma etching ntawm silicon dioxide zaj duab xis: Silicon dioxide zaj duab xis feem ntau yog etched siv etching gases uas muaj fluorine, xws li CF4, CHF3, C2F6, SF6 thiab C3F8. Cov pa roj carbon uas muaj nyob rau hauv cov roj etching tuaj yeem hnov mob nrog cov pa oxygen hauv txheej oxide los tsim cov khoom siv CO thiab CO2, yog li tshem tawm cov pa oxygen hauv txheej oxide. CF4 yog feem ntau siv etching gas. Thaum CF4 sib tsoo nrog cov hluav taws xob hluav taws xob siab, ntau yam ions, radicals, atoms thiab dawb radicals raug tsim. Fluorine dawb radicals tuaj yeem ua tshuaj lom nrog SiO2 thiab Si los tsim cov silicon tetrafluoride (SiF4).

• Plasma etching ntawm silicon nitride zaj duab xis: Silicon nitride zaj duab xis tuaj yeem etched siv plasma etching nrog CF4 lossis CF4 sib xyaw roj (nrog O2, SF6 thiab NF3). Rau Si3N4 zaj duab xis, thaum CF4-O2 plasma los yog lwm yam roj plasma uas muaj F atoms yog siv rau etching, tus nqi ntawm silicon nitride tuaj yeem ncav cuag 1200Å / min, thiab etching selectivity yuav siab li 20: 1. Cov khoom tseem ceeb yog volatile silicon tetrafluoride (SiF4) uas yooj yim muab rho tawm.

3. Ib leeg siv lead ua silicon etching

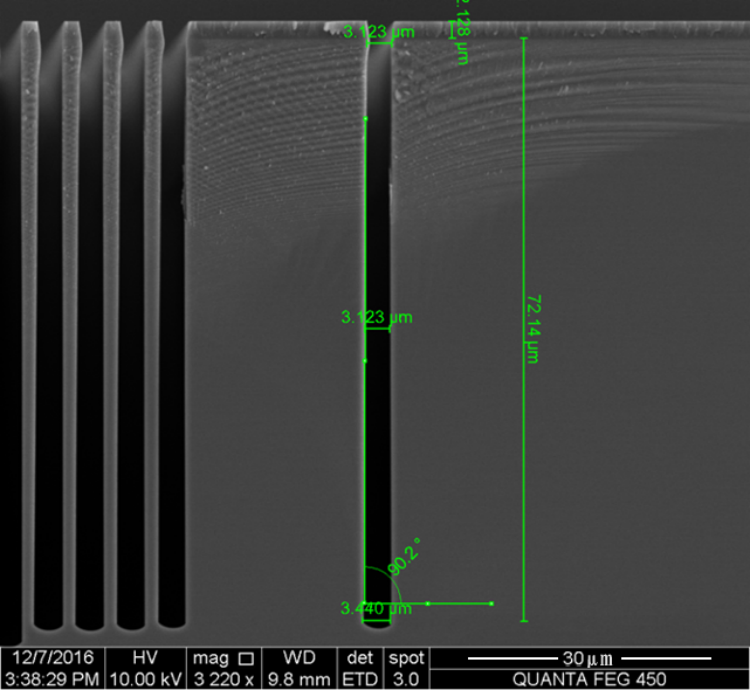

Ib leeg siv lead ua silicon etching feem ntau yog siv los tsim qhov ntiav trench cais (STI). Cov txheej txheem no feem ntau suav nrog cov txheej txheem tawg thiab txheej txheem etching tseem ceeb. Cov txheej txheem tawg siv SiF4 thiab NF roj los tshem tawm cov txheej txheem oxide ntawm ib qho siv lead ua silicon los ntawm kev muaj zog ion bombardment thiab cov tshuaj fluorine cov ntsiab lus; Lub ntsiab etching siv hydrogen bromide (HBr) ua lub ntsiab etchant. Cov bromine radicals decomposed los ntawm HBr nyob rau hauv lub plasma ib puag ncig react nrog silicon los tsim volatile silicon tetrabromide (SiBr4), yog li tshem tawm silicon. Ib leeg siv lead ua silicon etching feem ntau yog siv lub tshuab inductively ua ke nrog plasma etching tshuab.

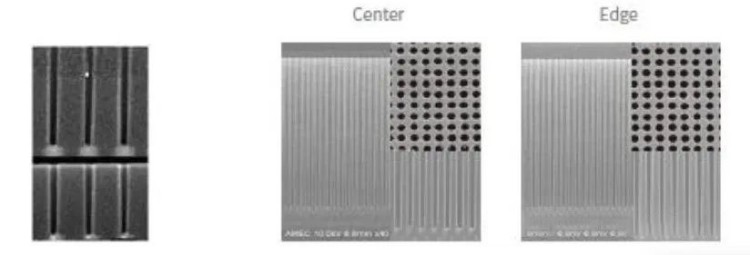

4. Polysilicon Etching

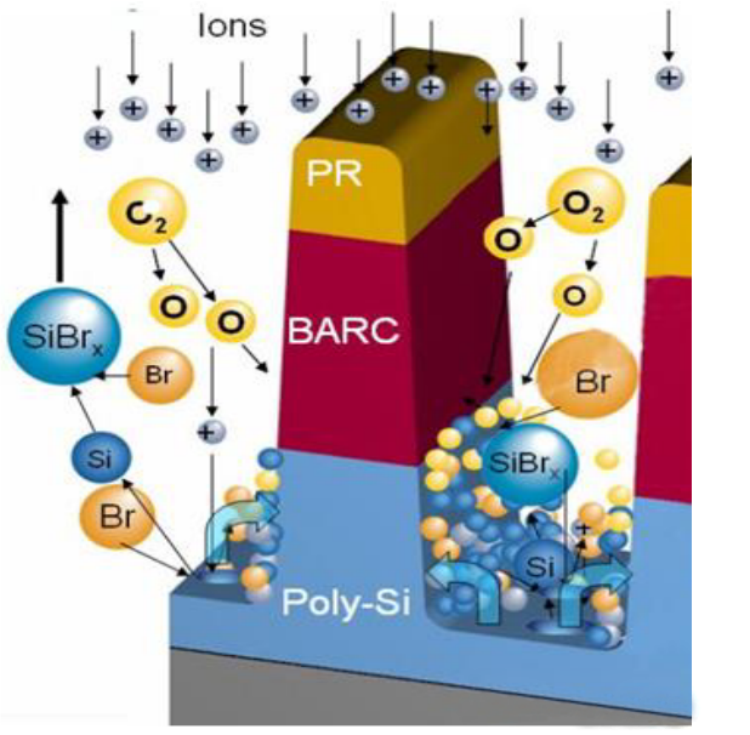

Polysilicon etching yog ib qho ntawm cov txheej txheem tseem ceeb uas txiav txim siab lub rooj vag loj ntawm cov transistors, thiab lub rooj vag loj cuam tshuam ncaj qha rau kev ua haujlwm ntawm kev sib xyaw ua ke. Polysilicon etching yuav tsum muaj kev xaiv zoo. Halogen gases xws li chlorine (Cl2) feem ntau yog siv los ua kom tiav anisotropic etching, thiab muaj qhov zoo ntawm qhov sib piv (txog 10: 1). Bromine-based gases xws li hydrogen bromide (HBr) tuaj yeem tau txais kev xaiv ntau dua (txog 100: 1). Kev sib xyaw ntawm HBr nrog cov tshuaj chlorine thiab oxygen tuaj yeem ua rau nce qhov etching. Cov khoom siv tshuaj tiv thaiv ntawm halogen roj thiab silicon tso rau ntawm phab ntsa los ua lub luag haujlwm tiv thaiv. Polysilicon etching feem ntau yog siv lub tshuab plasma etching inductively.

Txawm hais tias nws yog capacitively txuas plasma etching los yog inductively txuas plasma etching, txhua tus muaj nws tus kheej zoo thiab cov yam ntxwv. Xaiv lub tshuab etching uas tsim nyog tuaj yeem tsis tsuas yog txhim kho kev tsim khoom, tab sis kuj ua kom cov txiaj ntsig ntawm cov khoom kawg.

Post lub sij hawm: Nov-12-2024