Tam sim no, tiam thib peb ntawm semiconductors yog dominated los ntawmsilicon carbide. Nyob rau hauv tus nqi qauv ntawm nws cov khoom siv, lub substrate account rau 47%, thiab cov epitaxy account rau 23%. Ob qho tib si suav nrog kwv yees li 70%, uas yog qhov tseem ceeb tshaj plaws ntawm covsilicon carbidentaus ntawv manufacturing kev lag luam saw.

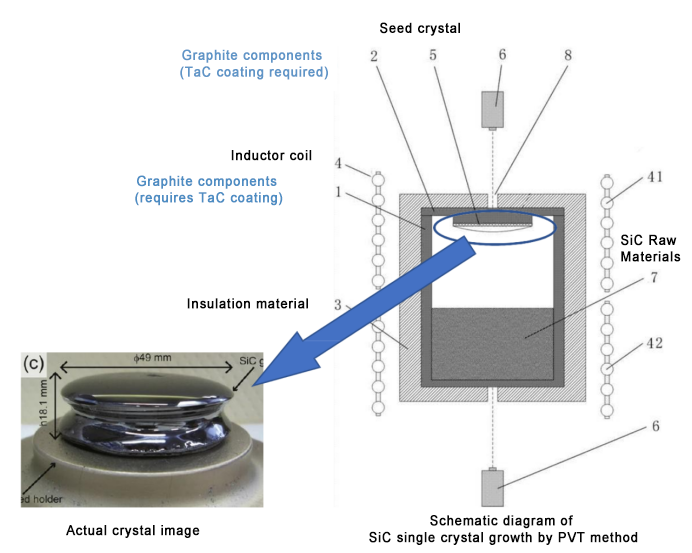

Feem ntau siv txoj kev npajsilicon carbideib leeg muaju yog PVT (lub cev vapor thauj) txoj kev. Lub hauv paus ntsiab lus yog ua kom cov ntaub ntawv raw nyob rau hauv qhov kub thiab txias thiab cov noob siv lead ua nyob rau hauv ib cheeb tsam uas tsis tshua muaj kub. Cov khoom siv raw ntawm qhov kub siab dua decompose thiab ncaj qha tsim cov roj theem yam tsis muaj kua theem. Cov roj theem cov khoom no raug thauj mus rau cov noob siv lead ua nyob rau hauv kev tsav tsheb ntawm axial kub gradient, thiab nucleate thiab loj hlob ntawm cov noob siv lead ua los tsim ib lub silicon carbide ib leeg siv lead ua. Tam sim no, cov tuam txhab txawv teb chaws xws li Cree, II-VI, SiCrystal, Dow thiab cov tuam txhab hauv tsev xws li Tianyue Advanced, Tianke Heda, thiab Century Golden Core txhua tus siv txoj kev no.

Muaj ntau tshaj 200 siv lead ua cov ntaub ntawv ntawm silicon carbide, thiab kev tswj kom meej heev yuav tsum tsim kom muaj ib daim ntawv siv lead ua uas yuav tsum tau (lub ntsiab yog 4H siv lead ua daim ntawv). Raws li Tianyue Advanced's prospectus, lub tuam txhab cov khoom siv lead ua yields hauv 2018-2020 thiab H1 2021 yog 41%, 38.57%, 50.73% thiab 49.90% feem, thiab cov substrate yields yog 72.61%, 75.75%, 75.15%. raws. Tam sim no, cov txiaj ntsig tau zoo tsuas yog 37.7%. Siv cov txheej txheem PVT tseem ceeb ua piv txwv, cov txiaj ntsig qis feem ntau yog vim muaj cov teeb meem hauv qab no hauv SiC substrate npaj:

1. Kev tswj qhov kub thiab txias: SiC siv lead ua rods yuav tsum tau ua nyob rau ntawm qhov kub ntawm 2500 ℃, thaum silicon crystals tsuas yog xav tau 1500 ℃, yog li yuav tsum tau tshwj xeeb ib leeg siv lead ua rauv, thiab kev loj hlob kub yuav tsum tau tswj kom meej thaum lub sij hawm tsim khoom. , uas yog qhov nyuaj heev los tswj.

2. Kev ua haujlwm qeeb qeeb: qhov kev loj hlob ntawm cov khoom siv silicon ib txwm yog 300 hli hauv ib teev, tab sis silicon carbide ib leeg tuaj yeem loj hlob 400 microns ib teev, uas yog ze li ntawm 800 npaug ntawm qhov sib txawv.

3. Cov kev xav tau siab rau cov khoom tsis zoo, thiab lub thawv dub tawm los yog qhov nyuaj rau kev tswj lub sijhawm: Cov ntsiab lus tseem ceeb ntawm SiC wafers muaj xws li microtube ntom, dislocation ceev, resistivity, warpage, nto roughness, thiab lwm yam. Thaum lub sij hawm siv lead ua kev loj hlob, nws yog tsim nyog los tswj cov kev txwv xws li silicon-carbon piv, kev loj hlob kub gradient, siv lead ua loj hlob tus nqi, thiab airflow siab. Txwv tsis pub, polymorphic inclusions yuav tshwm sim, uas ua rau cov crystals tsis tsim nyog. Nyob rau hauv lub thawv dub ntawm lub graphite crucible, nws yog tsis yooj yim sua los soj ntsuam cov siv lead ua kev loj hlob raws li txoj cai nyob rau hauv lub sij hawm ntawm lub sij hawm, thiab heev meej thermal teb tswj, cov khoom txuam, thiab kev tsub zuj zuj yuav tsum tau.

4. Qhov nyuaj ntawm kev nthuav dav siv lead ua: Raws li kev thauj mus los ntawm cov roj theem, cov thev naus laus zis ntawm SiC siv lead ua kev loj hlob yog qhov nyuaj heev. Raws li cov siv lead ua loj zuj zus, nws txoj kev loj hlob nyuaj nce exponentially.

5. Feem ntau tsis tshua muaj yield: Tsawg yield yog tsim los ntawm ob qhov txuas: (1) Crystal rod yield = semiconductor-qib crystal rod output/(semiconductor-qib crystal rod output + non-semiconductor-qib crystal rod output) × 100%; (2) Substrate yield = tsim nyog substrate tso zis / (tsim substrate tso zis + unqualified substrate tso zis) × 100%.

Nyob rau hauv kev npaj ntawm high-zoo thiab high-yieldsilicon carbide substrate, cov tub ntxhais xav tau cov ntaub ntawv thermal zoo dua kom tswj tau qhov kub thiab txias. Cov khoom siv thermal field crucible tam sim no yog cov khoom siv high-purity graphite structural qhov chaw, uas yog siv los ua kom sov thiab yaj carbon hmoov thiab silicon hmoov thiab ua kom sov. Graphite cov ntaub ntawv muaj cov yam ntxwv ntawm lub zog tshwj xeeb thiab cov qauv tshwj xeeb, zoo thermal poob siab tsis kam thiab corrosion kuj, tab sis lawv muaj qhov tsis zoo ntawm kev ua kom yooj yim oxidized nyob rau hauv high-temperature oxygen ib puag ncig, tsis tiv taus ammonia, thiab tsis muaj khawb kuj. Nyob rau hauv cov txheej txheem ntawm silicon carbide ib leeg siv lead ua kev loj hlob thiabsilicon carbide epitaxial waferntau lawm, nws yog ib qho nyuaj kom tau raws li tib neeg cov kev xav tau ntxiv rau kev siv cov khoom siv graphite, uas txwv tsis pub nws txoj kev loj hlob thiab kev siv tswv yim. Yog li ntawd, cov txheej txheem kub kub xws li tantalum carbide tau pib tshwm sim.

2. Cov yam ntxwv ntawmTantalum Carbide Txheej

TaC ceramic muaj qhov melting point txog 3880 ℃, siab hardness (Mohs hardness 9-10), thermal conductivity loj (22W·m-1·K−1), loj dabtsi yog khoov zog (340-400MPa), thiab me me thermal expansion coefficient (6.6 × 10-6K-1), thiab nthuav tawm cov thermochemical stability zoo thiab lub cev zoo heev. Nws muaj cov tshuaj zoo sib xws thiab cov khoom siv sib xyaw nrog graphite thiab C / C cov ntaub ntawv sib xyaw. Yog li ntawd, TaC txheej yog dav siv nyob rau hauv aerospace thermal tiv thaiv, ib qho kev loj hlob siv lead ua, lub zog hluav taws xob, thiab cov khoom siv kho mob.

TaC-coatedgraphite muaj cov tshuaj tiv thaiv corrosion zoo dua li liab qab graphite lossis SiC-coated graphite, tuaj yeem siv ruaj khov ntawm qhov kub ntawm 2600 °, thiab tsis hnov mob nrog ntau cov hlau. Nws yog txheej txheej zoo tshaj plaws nyob rau hauv peb tiam semiconductor ib leeg siv lead ua kev loj hlob thiab wafer etching scenarios. Nws tuaj yeem txhim kho kev tswj qhov kub thiab txias thiab impurities hauv cov txheej txheem thiab npajzoo silicon carbide wafersthiab hais txogepitaxial wafers. Nws yog tshwj xeeb tshaj yog haum rau loj hlob GaN los yog AlN ib leeg muaju nrog MOCVD cov cuab yeej thiab loj hlob SiC ib leeg muaju nrog PVT cov cuab yeej, thiab qhov zoo ntawm cov loj hlob ib leeg muaju yog ho txhim kho.

III. Qhov zoo ntawm Tantalum Carbide Coated Devices

Kev siv Tantalum Carbide TaC txheej tuaj yeem daws cov teeb meem ntawm cov khoom siv lead ua tsis zoo thiab txhim kho cov khoom siv lead ua kom zoo. Nws yog ib qho ntawm cov kev qhia tseem ceeb ntawm "kev loj hlob sai, loj hlob tuab, thiab loj hlob ntev". Kev tshawb fawb kev lag luam kuj tau qhia tias Tantalum Carbide Coated Graphite Crucible tuaj yeem ua tiav cov cua sov zoo sib xws, yog li muab cov txheej txheem zoo tswj rau SiC ib leeg siv lead ua kev loj hlob, yog li txo qis qhov tshwm sim ntawm polycrystalline tsim ntawm ntug ntawm SiC muaju. Tsis tas li ntawd, Tantalum Carbide Graphite Txheej muaj ob qhov zoo:

(I) Txo cov SiC Defects

Hais txog kev tswj SiC ib leeg siv lead ua tsis xws luag, feem ntau muaj peb txoj hauv kev tseem ceeb. Ntxiv rau kev txhim kho kev loj hlob tsis zoo thiab cov khoom siv zoo (xws li SiC qhov hmoov), siv Tantalum Carbide Coated Graphite Crucible kuj tuaj yeem ua tiav cov khoom siv lead ua zoo.

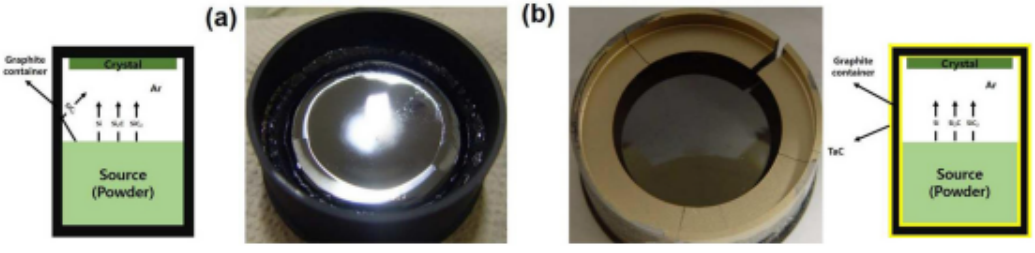

Schematic daim duab ntawm cov pa graphite crucible (a) thiab TAC coated crucible (b)

Raws li kev tshawb fawb los ntawm University of Eastern Europe hauv Kaus Lim Kauslim, lub ntsiab impurity hauv SiC siv lead ua kev loj hlob yog nitrogen, thiab tantalum carbide coated graphite crucibles tuaj yeem txwv cov nitrogen incorporation ntawm SiC crystals, yog li txo qhov tsim ntawm qhov tsis xws luag xws li micropipes thiab txhim kho siv lead ua. zoo. Cov kev tshawb fawb tau pom tias nyob rau hauv tib lub sijhawm, cov neeg nqa khoom ntau ntawm SiC wafers loj hlob hauv cov pa graphite crucibles thiab TAC coated crucibles yog kwv yees li 4.5 × 1017 / cm thiab 7.6 × 1015 / cm, feem.

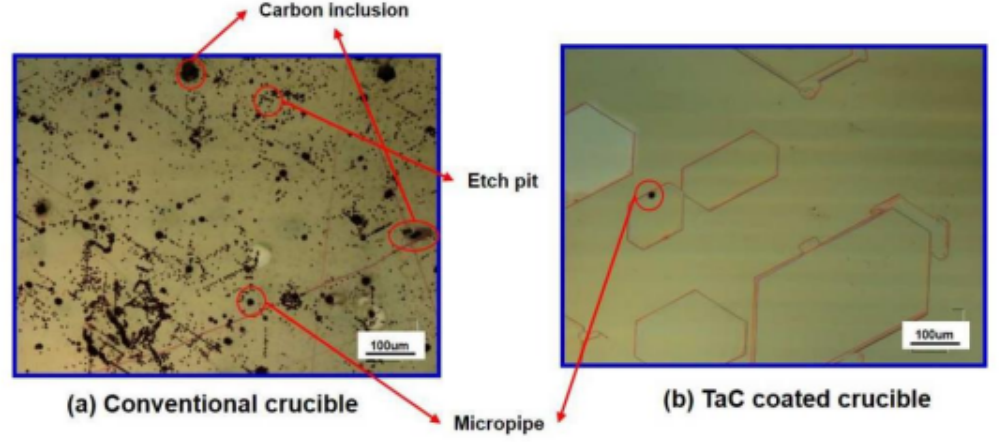

Kev sib piv ntawm qhov tsis xws luag hauv SiC ib qho crystals loj hlob hauv cov pa graphite crucibles (a) thiab TAC coated crucibles (b)

(II) Txhim kho lub neej ntawm graphite crucibles

Tam sim no, tus nqi ntawm SiC crystals tseem nyob siab, uas tus nqi ntawm graphite consumables suav txog li 30%. Lub ntsiab tseem ceeb ntawm kev txo cov nqi ntawm cov khoom siv graphite yog ua kom nws lub neej ua haujlwm. Raws li cov ntaub ntawv los ntawm pab pawg tshawb fawb Askiv, tantalum carbide txheej tuaj yeem txuas ntxiv lub neej kev pab cuam ntawm graphite Cheebtsam los ntawm 30-50%. Raws li qhov kev suav no, tsuas yog hloov tantalum carbide coated graphite tuaj yeem txo tus nqi ntawm SiC crystals los ntawm 9% -15%.

4. Tantalum carbide txheej txheej txheej txheem

TaC txheej txheej kev npaj tuaj yeem muab faib ua peb pawg: txheej txheem txheej txheej, txheej txheej ua kua theem thiab txheej txheem roj. Cov txheej txheem txheej txheem feem ntau suav nrog txoj kev txo qis thiab cov txheej txheem tshuaj; Txoj kev ua kua theem muaj xws li molten ntsev txoj kev, sol-gel method (Sol-Gel), slurry-sintering method, plasma spraying method; Cov txheej txheem roj muaj xws li tshuaj vapor deposition (CVD), tshuaj vapor infiltration (CVI) thiab lub cev vapor deposition (PVD). Cov txheej txheem sib txawv muaj lawv tus kheej qhov zoo thiab qhov tsis zoo. Ntawm lawv, CVD yog ib qho kev paub tab thiab siv dav rau kev npaj TaC txheej. Nrog rau kev txhim kho tas mus li ntawm cov txheej txheem, cov txheej txheem tshiab xws li cov hlau kub chemical vapor deposition thiab ion beam pab tshuaj vapor deposition tau tsim.

TaC txheej hloov cov ntaub ntawv carbon feem ntau suav nrog graphite, carbon fiber, thiab carbon / carbon composite cov ntaub ntawv. Cov txheej txheem rau kev npaj TaC txheej ntawm graphite muaj xws li plasma spraying, CVD, slurry sintering, thiab lwm yam.

Qhov zoo ntawm CVD txoj kev: CVD txoj kev npaj TaC coatings yog raws li tantalum halide (TaX5) raws li tantalum qhov chaw thiab hydrocarbon (CnHm) raws li carbon qhov chaw. Raws li qee qhov xwm txheej, lawv tau decomposed rau hauv Ta thiab C raws li, thiab tom qab ntawd cuam tshuam nrog ib leeg kom tau txais TaC txheej. CVD txoj kev tuaj yeem ua tiav ntawm qhov ntsuas kub qis, uas tuaj yeem zam qhov tsis xws luag thiab txo cov khoom siv hluav taws xob los ntawm kev npaj kub kub lossis kev kho cov txheej txheem rau qee yam. Cov muaj pes tsawg leeg thiab cov qauv ntawm txheej yog tswj tau, thiab nws muaj qhov zoo ntawm purity siab, siab ceev, thiab uniform thickness. Qhov tseem ceeb tshaj, muaj pes tsawg leeg thiab cov qauv ntawm TaC coatings npaj los ntawm CVD tuaj yeem tsim thiab tswj tau yooj yim. Nws yog ib qho kev paub tab thiab siv dav rau kev npaj cov txheej txheem TaC zoo.

Cov ntsiab lus tseem ceeb ntawm cov txheej txheem muaj xws li:

A. Gas flow rate (tantalum source, hydrocarbon gas li carbon source, carrier gas, dilution gas Ar2, txo cov pa roj H2): Qhov kev hloov ntawm cov roj ntws tau muaj kev cuam tshuam zoo rau qhov kub thiab txias, qhov chaw siab, thiab cov roj ntws hauv cov tshuaj tiv thaiv chamber, ua rau muaj kev hloov pauv ntawm cov khoom sib xyaw, cov qauv, thiab kev ua haujlwm ntawm txheej txheej. Kev nce Ar txaus tus nqi yuav ua rau qeeb ntawm txheej txheej loj hlob thiab txo cov qoob loo loj, thaum lub molar loj piv ntawm TaCl5, H2, thiab C3H6 cuam tshuam rau cov txheej txheem txheej. Cov molar ratio ntawm H2 rau TaCl5 yog (15-20): 1, uas yog tsim nyog. Cov molar piv ntawm TaCl5 rau C3H6 yog theoretically ze rau 3: 1. Cov TaCl5 lossis C3H6 ntau dhau yuav ua rau tsim cov Ta2C lossis cov pa roj carbon dawb, cuam tshuam rau qhov zoo ntawm wafer.

B. Deposition kub: qhov kub ntawm deposition ntau dua, qhov ceev ntawm deposition npaum li cas, lub grain loj dua, thiab lub rougher txheej. Tsis tas li ntawd, qhov kub thiab ceev ntawm hydrocarbon decomposition rau hauv C thiab TaCl5 decomposition rau hauv Ta yog txawv, thiab Ta thiab C yog feem ntau tsim Ta2C. Kub muaj kev cuam tshuam zoo rau TaC txheej hloov cov ntaub ntawv carbon. Raws li qhov kub ntawm deposition nce, qhov deposition tus nqi nce, particle loj nce, thiab cov particle zoo hloov ntawm spherical mus rau polyhedral. Tsis tas li ntawd, qhov kub ntawm qhov deposition ntau dua, qhov decomposition ntawm TaCl5 sai dua, qhov tsawg dua C dawb yuav, qhov kev ntxhov siab ntau dua hauv cov txheej, thiab cov kab nrib pleb yuav yooj yim tsim. Txawm li cas los xij, qhov ntsuas kub qis qis yuav ua rau cov txheej txheem qis dua, lub sij hawm tso nyiaj ntev dua, thiab cov nqi raw khoom ntau dua.

C. Deposition siab: Deposition siab yog ze ze rau lub zog dawb ntawm cov khoom nto thiab yuav cuam tshuam rau lub sij hawm nyob rau hauv cov tshuaj tiv thaiv chamber, yog li cuam tshuam rau lub nucleation ceev thiab particle loj ntawm txheej. Raws li cov deposition siab nce, lub sij hawm nyob rau hauv cov pa roj yuav ntev dua, cov reactants muaj ntau lub sij hawm rau undergo nucleation cov tshuaj tiv thaiv, cov tshuaj tiv thaiv tus nqi nce, cov hais ua loj, thiab cov txheej yuav thicker; conversely, raws li cov deposition siab txo, cov tshuaj tiv thaiv roj nyob rau lub sij hawm luv luv, cov tshuaj tiv thaiv tus nqi qeeb, cov hais ua me me, thiab cov txheej yog thinner, tab sis lub deposition siab muaj me ntsis cuam tshuam rau cov siv lead ua qauv thiab muaj pes tsawg leeg ntawm txheej.

V. Txoj kev loj hlob ntawm tantalum carbide txheej

Lub thermal expansion coefficient ntawm TaC (6.6 × 10−6K−1) yog qhov txawv me ntsis ntawm cov khoom siv carbon xws li graphite, carbon fiber, thiab C / C cov ntaub ntawv sib xyaw, uas ua rau ib-theem TaC coatings nquag tawg thiab ntog. Txhawm rau txhawm rau txhim kho qhov ablation thiab oxidation tsis kam, kub-kub txhua yam ruaj khov, thiab kub-kub tshuaj corrosion kuj ntawm TaC txheej, cov kws tshawb fawb tau tshawb fawb txog cov txheej txheem txheej txheej xws li cov txheej txheem txheej txheej, cov txheej txheem txheej txheej txheej txheej, thiab gradient. txheej txheej.

Cov txheej txheem txheej txheej yog kaw cov kab nrib pleb ntawm ib txheej txheej. Feem ntau, lwm cov txheej txheej tau nkag mus rau hauv qhov chaw lossis txheej txheej ntawm TaC los tsim cov txheej txheem txheej txheej; cov khoom siv ntxiv dag zog rau txheej txheej HfC, ZrC, thiab lwm yam muaj tib lub ntsej muag-centered cubic qauv li TaC, thiab ob lub carbides tuaj yeem ua rau infinitely soluble hauv ib leeg los tsim cov qauv kev daws teeb meem. Lub Hf (Ta) C txheej yog tsis muaj tawg thiab muaj adhesion zoo rau cov khoom sib xyaw C / C. Lub txheej muaj kev ua haujlwm zoo los tiv thaiv ablation; gradient txheej txheej txheej gradient txheej yog hais txog cov txheej txheem txheej txheej nrog nws cov thickness kev taw qhia. Cov qauv tuaj yeem txo cov kev ntxhov siab sab hauv, txhim kho qhov tsis sib haum ntawm thermal expansion coefficients, thiab tsis txhob tawg.

(II) Tantalum carbide txheej khoom siv

Raws li kev txheeb cais thiab kev kwv yees ntawm QYR (Hengzhou Bozhi), lub ntiaj teb tantalum carbide txheej kev lag luam muag hauv xyoo 2021 tau mus txog US $ 1.5986 lab (tsis suav nrog Cree tus kheej tsim thiab tus kheej muab tantalum carbide txheej khoom), thiab nws tseem nyob rau thaum ntxov. theem ntawm kev txhim kho kev lag luam.

1. Crystal expansion rings thiab crucibles yuav tsum tau siv rau kev loj hlob siv lead ua: Raws li 200 siv lead ua kev loj hlob furnaces ib lub lag luam, kev lag luam feem ntawm TaC coated li xav tau los ntawm 30 lub tuam txhab siv lead ua kev loj hlob yog li 4.7 billion yuan.

2. TaC trays: Txhua lub tais tuaj yeem nqa 3 wafers, txhua lub tais tuaj yeem siv tau 1 lub hlis, thiab 1 lub tais yog siv rau txhua 100 wafers. 3 lab wafers xav tau 30,000 TaC tais, txhua lub tais yog li 20,000 daim, thiab xav tau 600 lab txhua xyoo.

3. Lwm yam kev txo cov pa roj carbon monoxide. Xws li cov cua kub kub hauv ob sab phlu, CVD nozzle, cov kav dej rauv, thiab lwm yam, txog 100 lab.

Post lub sij hawm: Jul-02-2024