Silicon carbide (SiC)Cov khoom siv muaj qhov zoo ntawm qhov dav bandgap, siab thermal conductivity, siab tseem ceeb heev tawg teb zog, thiab siab saturated electron drift tshaj tawm, ua rau nws zoo heev nyob rau hauv lub semiconductor manufacturing teb. SiC ib leeg muaju feem ntau yog tsim los ntawm lub cev vapor thauj (PVT) txoj kev. Cov kauj ruam tshwj xeeb ntawm txoj kev no suav nrog muab SiC hmoov rau hauv qab ntawm graphite crucible thiab muab SiC noob siv lead ua rau saum lub crucible. Cov graphitecrucibleyog rhuab mus rau sublimation kub ntawm SiC, ua rau cov hmoov SiC decompose rau hauv vapor theem tshuaj xws li Si vapor, Si2C, thiab SiC2. Raws li kev cuam tshuam ntawm axial kub gradient, cov tshuaj vaporized sublimate mus rau sab saum toj ntawm lub crucible thiab condense nyob rau saum npoo ntawm SiC noob siv lead ua, crystallizing rau hauv SiC ib leeg muaju.

Tam sim no, txoj kab uas hla ntawm cov noob siv lead ua siv nyob rau hauvSiC ib leeg siv lead ua loj hlobxav kom phim lub hom phiaj siv lead ua txoj kab uas hla. Thaum lub sij hawm kev loj hlob, cov noob siv lead ua yog tsau rau ntawm cov noob nyob rau sab saum toj ntawm crucible siv cov nplaum. Txawm li cas los xij, txoj kev kho cov noob siv lead ua no tuaj yeem ua rau muaj teeb meem xws li voids nyob rau hauv cov nplaum txheej vim cov yam ntxwv xws li qhov tseeb ntawm cov noob lub ntsej muag thiab qhov sib xws ntawm cov nplaum txheej, uas tuaj yeem ua rau hexagonal void defects. Cov no suav nrog kev txhim kho lub tiaj tus ntawm cov graphite phaj, ua kom qhov sib xws ntawm cov nplaum txheej tuab, thiab ntxiv cov txheej txheem tsis yooj yim. Txawm tias cov kev siv zog no, tseem muaj teeb meem nrog qhov ntom ntawm cov nplaum txheej, thiab muaj kev pheej hmoo ntawm cov noob siv lead ua detachment. Los ntawm kev siv cov txheej txheem ntawm kev sib txuas covwafermus rau graphite ntawv thiab sib tshooj nws nyob rau sab saum toj ntawm lub crucible, qhov ntom ntawm cov nplaum txheej tuaj yeem txhim kho, thiab kev tshem tawm ntawm wafer tuaj yeem tiv thaiv.

1. Kev sim txheej txheem:

Cov wafers siv nyob rau hauv qhov kev sim yog muaj muag6-nti N-hom SiC wafers. Photoresist yog siv los ntawm kev siv lub tshuab hluav taws xob. Adhesion yog tiav los ntawm kev siv tus kheej-tsim noob kub xovxwm rauv.

1.1 Noob Crystal Fixation Scheme:

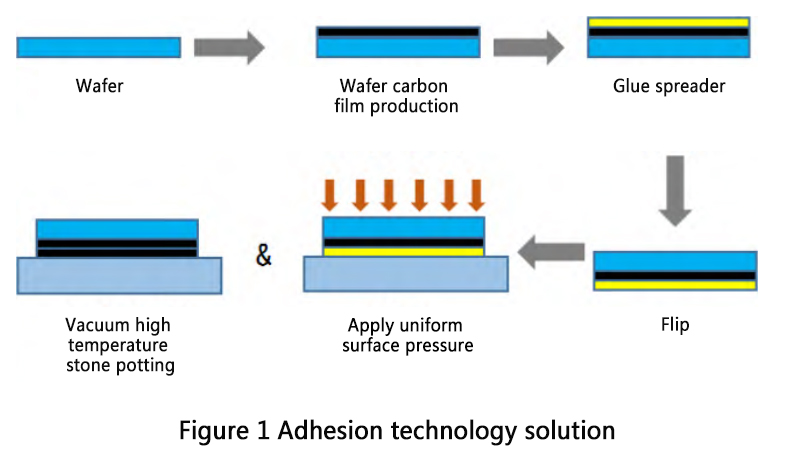

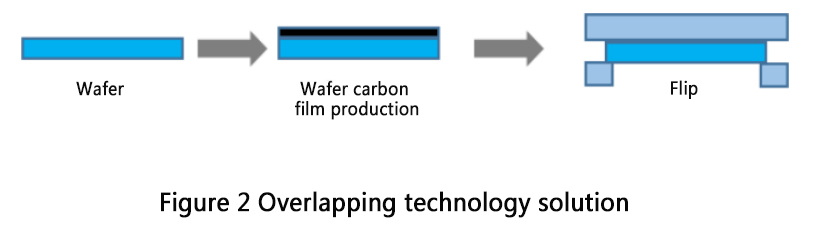

Tam sim no, SiC noob siv lead ua adhesion schemes tuaj yeem muab faib ua ob pawg: hom nplaum thiab hom ncua kev kawm.

Adhesive Type Scheme (Daim duab 1): Qhov no suav nrog kev sib koom ua keSiC wafermus rau graphite phaj nrog ib txheej ntawm graphite ntawv raws li ib tug tsis muaj txheej txheem kom tshem tawm qhov khoob ntawm lubSiC waferthiab graphite phaj. Hauv kev tsim khoom tiag tiag, lub zog sib txuas ntawm daim ntawv graphite thiab cov phaj graphite tsis muaj zog, ua rau cov noob siv lead ua detachment ntau zaus thaum lub sij hawm kev loj hlob ntawm qhov kub thiab txias, ua rau kev loj hlob tsis ua hauj lwm.

Suspension Type Scheme (Daim duab 2): Feem ntau, cov pa roj carbon monoxide yog tsim rau ntawm qhov sib txuas ntawm SiC wafer siv cov kua nplaum carbonization los yog txheej txheej. CovSiC waferyog tom qab ntawd clamped ntawm ob daim phiaj graphite thiab muab tso rau saum lub graphite crucible, kom ruaj ntseg thaum cov yeeb yaj kiab carbon tiv thaiv lub wafer. Txawm li cas los xij, tsim cov yeeb yaj kiab carbon los ntawm txheej txheej yog kim thiab tsis haum rau kev tsim khoom. Cov kua nplaum carbonization txoj kev yields inconsistent carbon zaj duab xis zoo, ua rau nws nyuaj kom tau ib tug zoo kawg nkaus ntom carbon zaj duab xis nrog muaj zog adhesion. Tsis tas li ntawd, clamping cov graphite daim hlau txo qhov kev loj hlob zoo ntawm wafer los ntawm kev thaiv ib feem ntawm nws qhov chaw.

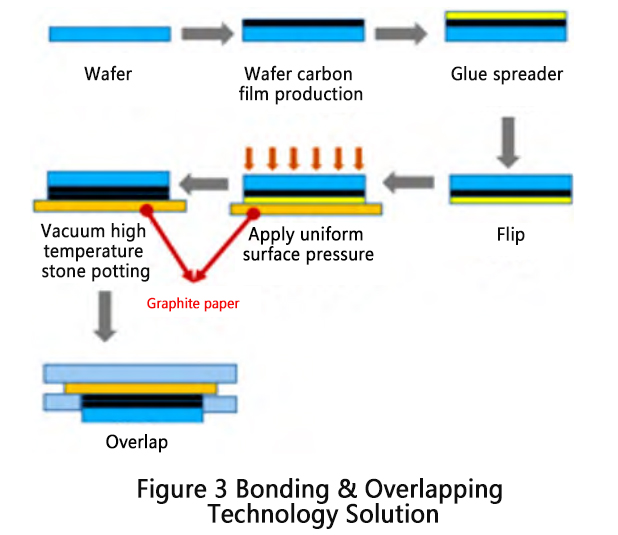

Raws li ob lub tswv yim saum toj no, cov txheej txheem tshiab nplaum thiab sib tshooj yog npaj (Daim duab 3):

Cov yeeb yaj kiab kuj tseem yog tsim rau ntawm qhov sib txuas ntawm SiC wafer siv cov kua nplaum carbonization, kom tsis txhob muaj teeb pom kev loj hauv qab teeb pom kev zoo.

SiC wafer npog nrog cov pa roj carbon zaj duab xis yog sib koom ua ke rau daim ntawv graphite, nrog rau qhov chaw sib txuas yog cov yeeb yaj kiab carbon. Lub nplaum txheej yuav tsum tshwm uniformly dub nyob rau hauv lub teeb.

Daim ntawv graphite yog clamped los ntawm graphite daim hlau thiab raug tshem tawm saum cov graphite crucible rau kev loj hlob siv lead ua.

1.2 Adhesive:

Lub viscosity ntawm photoresist ho cuam tshuam rau zaj duab xis thickness uniformity. Nyob rau tib lub nrawm nrawm, qis viscosity ua rau cov ntaub nplaum nyias nyias thiab ntau dua. Yog li ntawd, qhov tsawg-viscosity photoresist yog xaiv nyob rau hauv daim ntawv thov yuav tsum tau.

Thaum lub sij hawm kev sim, nws tau pom tias viscosity ntawm carbonizing adhesive cuam tshuam lub zog sib txuas ntawm cov yeeb yaj kiab carbon thiab wafer. Cov viscosity siab ua rau nws nyuaj rau kev siv cov txheej txheem sib npaug, thaum tsis tshua muaj viscosity ua rau lub zog tsis muaj zog, ua rau cov yeeb yaj kiab tawg thaum cov txheej txheem txuas ntxiv vim yog cov nplaum ntws thiab sab nraud. Los ntawm kev sim kev tshawb fawb, qhov viscosity ntawm carbonizing adhesive tau txiav txim siab yog 100 mPa·s, thiab cov nplaum nplaum viscosity tau teem rau 25 mPa·s.

1.3 Lub tshuab nqus tsev ua haujlwm:

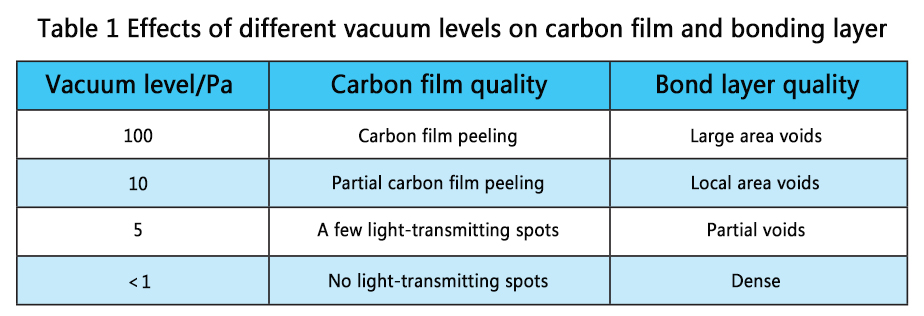

Cov txheej txheem ntawm kev tsim cov yeeb yaj kiab carbon ntawm SiC wafer koom nrog carbonizing cov nplaum txheej ntawm SiC wafer nto, uas yuav tsum tau ua nyob rau hauv lub tshuab nqus tsev lossis argon-tiv thaiv ib puag ncig. Cov txiaj ntsig kev sim qhia tau hais tias ib puag ncig tiv thaiv argon yog qhov tsim nyog rau kev tsim cov yeeb yaj kiab ntau dua li qhov chaw nqus tsev siab. Yog tias siv lub tshuab nqus tsev, lub tshuab nqus tsev yuav tsum yog ≤1 Pa.

Cov txheej txheem ntawm kev sib txuas ntawm SiC noob siv lead ua koom nrog kev sib koom ua ke ntawm SiC wafer rau graphite phaj / graphite ntawv. Xav txog cov nyhuv erosive ntawm oxygen ntawm graphite cov ntaub ntawv ntawm qhov kub thiab txias, cov txheej txheem no yuav tsum tau ua nyob rau hauv lub tshuab nqus tsev. Qhov cuam tshuam ntawm cov qib nqus tsev sib txawv ntawm cov nplaum nplaum tau kawm. Cov txiaj ntsig kev sim tau pom nyob rau hauv Table 1. Nws tuaj yeem pom tau tias nyob rau hauv lub tshuab nqus tsev qis, cov pa oxygen molecules hauv huab cua tsis raug tshem tawm tag nrho, ua rau cov txheej nplaum tsis tiav. Thaum lub tshuab nqus tsev qis dua 10 Pa, cov nyhuv erosive ntawm oxygen molecules ntawm cov nplaum txheej yog txo qis. Thaum lub tshuab nqus tsev qis dua 1 Pa, cov nyhuv erosive raug tshem tawm tag nrho.

Post lub sij hawm: Jun-11-2024