Uas muaj ib tug ua tiav scientific zoo heev tswj txheej txheem, zoo heev thiab zoo heev kev ntseeg, peb khwv tau lub npe zoo thiab nyob rau hauv daim teb no rau OEM/ODM Tuam Tshoj Pob Zeb Diamond Silicon Carbide Dub Corundum Pob zeb Nqe rau Casting Industry Steelmaking Abrasive, Peb xav tias peb yuav los ua ib tug tus thawj coj hauv kev tsim thiab tsim cov khoom zoo thiab cov kev daws teeb meem hauv Suav teb thiab thoob ntiaj teb kev lag luam. Peb vam tias yuav koom tes nrog cov phooj ywg ntau dua rau kev sib nrig sib zoo.

Uas muaj kev ua tiav scientific zoo heev tswj txheej txheem, zoo heev thiab kev ntseeg zoo heev, peb tau txais lub npe zoo thiab nyob rau hauv daim teb no rauTuam Tshoj Tais Hom Sib Tsoo Pob Zeb thiab Lub Tais Loj Dawb Lub Tais Hom Sib Tsoo Pob Zeb, Peb tenet yog "kev ncaj ncees ua ntej, zoo tshaj plaws". Peb muaj kev ntseeg siab los muab kev pabcuam zoo thiab cov khoom zoo rau koj. Peb cia siab tias peb tuaj yeem tsim kom muaj kev sib koom tes ua lag luam nrog koj yav tom ntej!

Kev piav qhia

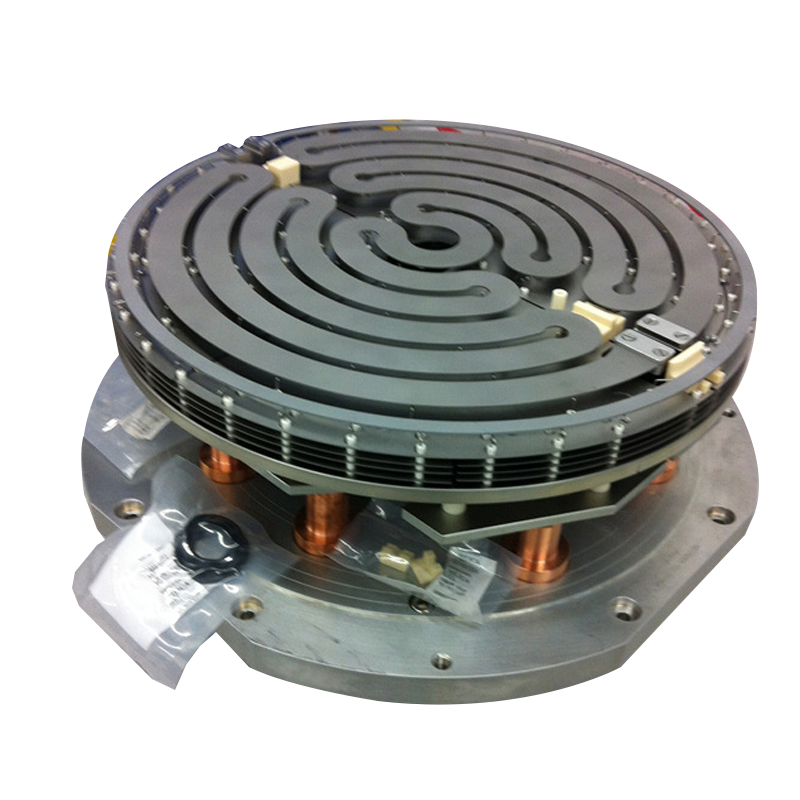

Silicon carbide sib tsoo nruas txais cov txheej txheem isostatic nias molding, ceev 3.09g / cm3, siab tshaj φ950mm, Vickers hardness 2550HV.

silicon carbide ceramic sib tsoo chim nyob rau hauv daim ntawv thov ntawm lub zog thiab kev tiv thaiv ib puag ncig Lub sensible tshav kub ntawm cov roj nyob rau hauv lub tshav kub exchanger ntawm silicon carbide ceramic sib tsoo chim yuav siv tau los ntxuav cov roj ncaj qha ntawm kub kub. Piv nrog rau ib txwm kub purification, thermal efficiency tau zoo heev. Kev siv ncaj qha ntawm qhov kub thiab txias purified gas rau roj turbine lub zog tsim muaj peev xwm txhim kho kev ua tau zoo ntawm cov khoom siv hluav taws xob, txo cov emission ntawm cov khoom tsis zoo thiab txuag dej.

![]()

![]()

Silicon carbide sib tsoo chim kom zoo dua

(1) Kev kub siab ua haujlwm, me me coefficient ntawm thermal expansion

Silicon carbide yog tsim los ntawm qhov kub thiab txias. Hauv qee qhov chaw kub kub, cov khoom siv yuav tsum muaj lub zog ua haujlwm, thiab ua tau raws li kev ua tiav, thiab silicon carbide ceramics tuaj yeem ua tiav ob lub ntsiab lus. Kev siv siab tshaj plaws ntawm silicon carbide yog li 800 ℃, thiab cov kabmob kub ntawm cov hlau tsuas yog 250 ℃. Los ntawm kev suav ntxhib, qhov nruab nrab thermal expansion coefficient ntawm SIC yog 4.4 × 10-6 / C nyob rau hauv thaj tsam ntawm 25 ~ 1400 ℃. Lub thermal expansion coefficient ntawm SIC yog tsawg dua li ntawm lwm yam abrasives thiab cov ntaub ntawv kub. Piv txwv li, cov coefficient ntawm thermal expansion ntawm corundum yuav siab li (7 ~ 8) × 10-6 / ℃.

(2) High thermal conductivity

Lub siab thermal conductivity ntawm SIC yog lwm yam tseem ceeb ntawm nws lub cev. Lub thermal conductivity ntawm silicon carbide ntau dua li ntawm lwm cov ntaub ntawv refractory thiab abrasives, txog 4 npaug ntawm corundum. Silicon carbide thermal expansion coefficient yog tsawg, siab thermal conductivity, ua rau nws cov khoom nyob rau hauv cov txheej txheem ntawm cua sov thiab txias nyob rau hauv tsawg thermal stress, uas kuj yog silicon carbide khoom thermal shock kuj yog tshwj xeeb yog vim li cas.

(3) Corrosion kuj

Silicon carbide vim nws qhov melting point (decomposition kub), tshuaj inertia thiab thermal shock kuj yog siab, tuaj yeem siv rau ntau yam khoom siv silicon carbide ceramic, xws li cov khoom siv hluav taws xob sib tsoo, qab nthab phaj thiab sagger, zinc smelting muaj ntsug. Lub tog raj kheej distillation rauv nrog silicon carbide cib, aluminium electrolytic cell hauv ob sab phlu, crucible, me me rauv khoom.

![]()

![]()

Daim ntawv thov corrosion kuj

1, zawv zawg qhov chaw (mechanical foob, tshuaj twj tso kua mis bearing, ncej)

2, crusher accessories (classifier, cua zeb, xuab zeb zeb)

3.Semiconductor manufacturing khoom qhov chaw (XY platform, MOCVD tais, tsom nplhaib, wafer chuck)

4. Qhov chaw ntawm lub tshuab molding (qhov chaw ntawm lub koob yees duab lens molding tshuab)

5 qhov hluav taws kub resistant (burner nozzle, kub ntsuas tshuab qhov chaw, molten hlau crucible)

6. Hnav-tiv taus qhov chaw (xuab zeb blasting tshuab nozzle, txhaj tshuaj blasting tshuab polishing tshuab hniav, faus pipeline tiv thaiv phaj, nuv ntses tackle qhia nplhaib)

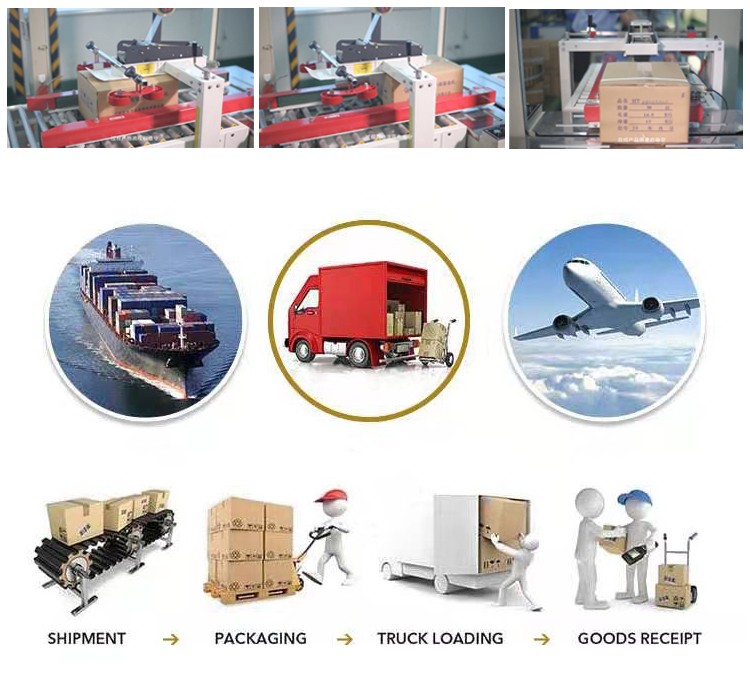

Kev thauj mus los

Vim li cas koj thiaj xaiv Wei Tai?

1) peb muaj cov khoom lag luam txaus lav.

2) kev ntim khoom ua kom cov khoom ruaj khov. Cov khoom yuav raug xa tuaj rau koj yam xyuam xim.

3) ntau logistics channel pab kom cov khoom xa tuaj rau koj.

FAQ

Q: Koj puas yog tuam txhab lag luam lossis chaw tsim khoom?

A: Peb yog ntau tshaj 10 vears Hoobkas nrog iso9001 ntawv pov thawj

Q: Koj lub sijhawm xa khoom ntev npaum li cas?

A: Feem ntau nws yog 3-5 hnub yog tias cov khoom muaj nyob hauv Tshuag, lossis 10-15 hnub yog tias cov khoom tsis nyob hauv Tshuag, nws yog raws li koj qhov ntau.

Q: Yuav ua li cas thiaj li tau txais cov qauv los kuaj koj qhov zoo?

A: Tom qab tus nqi lees paub, koj tuaj yeem xav tau cov qauv los kuaj xyuas peb cov khoom zoo. Yog tias koj tsuas yog xav tau tus qauv dawb los kuaj xyuas tus qauv tsim thiab zoo, peb yuav muab cov qauv dawb rau koj ntev npaum li koj them tus nqi thauj khoom.

Q: Koj cov nqe lus them nqi yog dab tsi?

A: Peb lees txais kev them nyiaj los ntawm Western union, Pavpal, Alibaba, T / TL / Cetc.. rau kev txiav txim ntau, peb ua 30% tso nyiaj tshuav ua ntej xa khoom.

Uas muaj ib tug ua tiav scientific zoo heev tswj txheej txheem, zoo heev thiab zoo heev kev ntseeg, peb khwv tau lub npe zoo thiab nyob rau hauv daim teb no rau OEM/ODM Tuam Tshoj Pob Zeb Diamond Silicon Carbide Dub Corundum Pob zeb Nqe rau Casting Industry Steelmaking Abrasive, Peb xav tias peb yuav los ua ib tug tus thawj coj hauv kev tsim thiab tsim cov khoom zoo thiab cov kev daws teeb meem hauv Suav teb thiab thoob ntiaj teb kev lag luam. Peb vam tias yuav koom tes nrog cov phooj ywg ntau dua rau kev sib nrig sib zoo.

OEM / ODM Tuam TshojTuam Tshoj Tais Hom Sib Tsoo Pob Zeb thiab Lub Tais Loj Dawb Lub Tais Hom Sib Tsoo Pob Zeb, Peb tenet yog "kev ncaj ncees ua ntej, zoo tshaj plaws". Peb muaj kev ntseeg siab los muab kev pabcuam zoo thiab cov khoom zoo rau koj. Peb cia siab tias peb tuaj yeem tsim kom muaj kev sib koom tes ua lag luam nrog koj yav tom ntej!

-

Lub koob npe nrov Silicon Carbide Qws Element, Si...

-

Kev cob qha Tuam Tshoj Silicon Carbide Nkoj, Holder ...

-

Teb chaws Europe style rau U Hom Sic Cua sov Element, Si ...

-

100% Original Anti-shock Silicon Carbide Cyclon...

-

Tuam Tshoj Customized Sic Heater Silicon Car...

-

Kub-muag Robust, Hnav-Resistant Steel Tube, ...