High-zoo los 1st; kev txhawb nqa yog qhov tseem ceeb; kev lag luam yog kev koom tes "yog peb lub tswv yim ua lag luam me uas tau ua haujlwm tsis tu ncua thiab ua raws los ntawm peb lub koom haum rau OEM / ODM Cov Khoom Siv Yooj Yim Txhim Kho Sic Heating Elements rau Cov Hluav Taws Xob Hluav Taws Xob, Peb tau tshawb nrhiav ua ntej los tsim kev sib txuas zoo thiab muaj txiaj ntsig nrog txhua tus neeg muab kev pabcuam hauv lub ntiaj chaw. Peb zoo siab tos txais koj los tham nrog peb kom pib sib tham txog yuav ua li cas peb tuaj yeem coj qhov no los ua.

High-zoo los 1st; kev txhawb nqa yog qhov tseem ceeb; kev lag luam yog kev koom tes "yog peb lub tswv yim ua lag luam me uas tau saib xyuas thiab ua raws li peb lub koom haum rauTuam Tshoj Heating Element thiab Sic Heating Elements, Peb lees paub rau pej xeem, kev koom tes, yeej-yeej qhov xwm txheej raws li peb lub hauv paus ntsiab lus, ua raws li lub tswv yim ntawm kev ua neej zoo, ua kom muaj kev ncaj ncees, ua siab dawb cia siab tias yuav tsim kom muaj kev sib raug zoo nrog ntau thiab ntau tus neeg siv khoom thiab cov phooj ywg, kom ua tiav qhov xwm txheej yeej-yeej thiab kev vam meej.

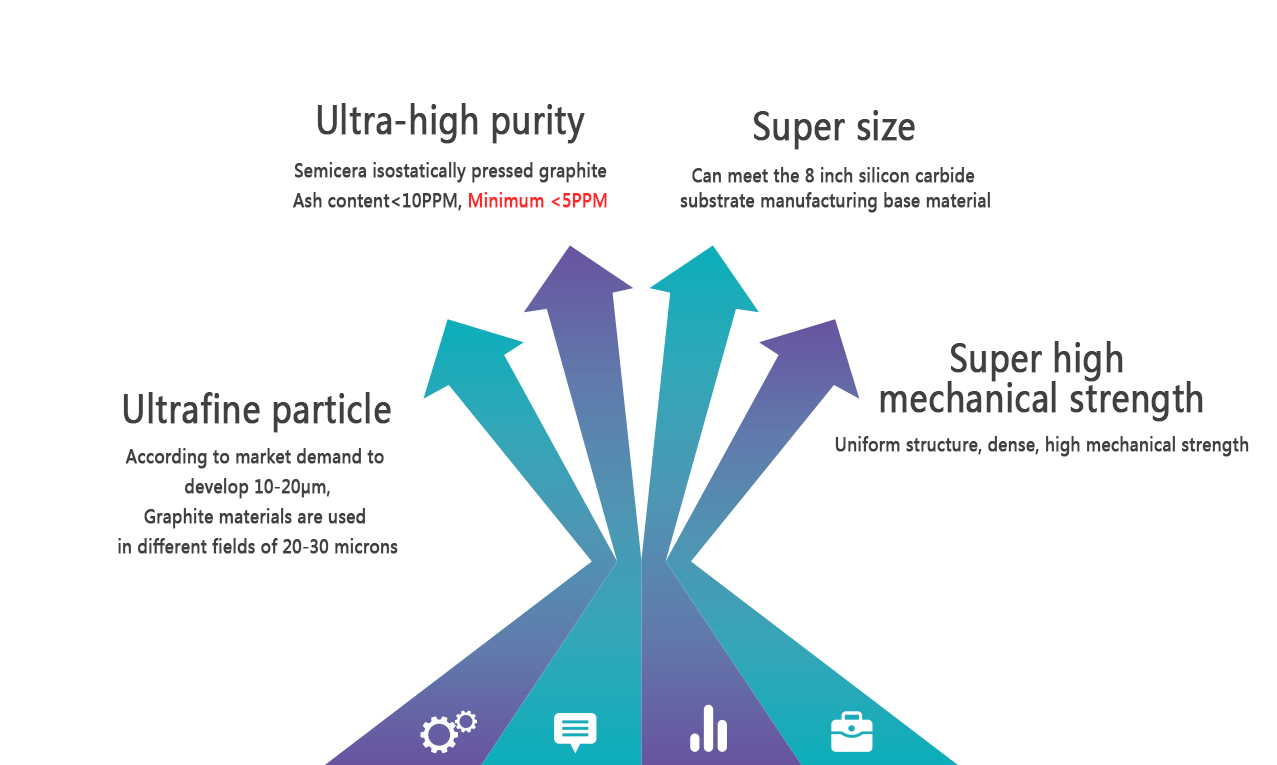

Cov khoom tseem ceeb ntawm semicera yog nplua particle isostatically pressed graphite siv nyob rau hauv semiconductors. Cov ntaub ntawv tseem ceeb ntawm lub ntiaj teb no siab tshaj German SGL thiab Japanese Toyo carbon cov khoom yog raws li nram no:

| Kev ua haujlwm parameter | semicera | SGL R6510 | TOYO IG 310 TSI |

| Qhov ceev (g / cm3) | 1.91 ib | 1.83 ib | 1.85 ib |

| Bending zog (MPa) | 63 | 60 | 49 |

| Compressive zog (MPa) | 135 | 130 | 103 |

| Ntug Hardness (HS) | 70 | 64 | 60 |

| Thermal conductivity (W / m · K) | 85 | 105 | 130 |

| Coefficient ntawm thermal expansion (10-6 / K) | 5.85 ib | 4.2 | 5.0 |

| Resistivity (μΩ) | 11-13 | 13 | 10 |

Kev ua tau zoo kom zoo dua:

1.Cov qauv yog zoo thiab ntom, thiab cov uniformity yog zoo.

2. Tsawg coefficient ntawm thermal expansion, zoo heev thermal shock kuj;

3. Isotropy;

4. Muaj zog tshuaj tiv thaiv;

5.Qhov zoo thermal thiab hluav taws xob conductivity;

6.Nws muaj cov khoom zoo heev machining.

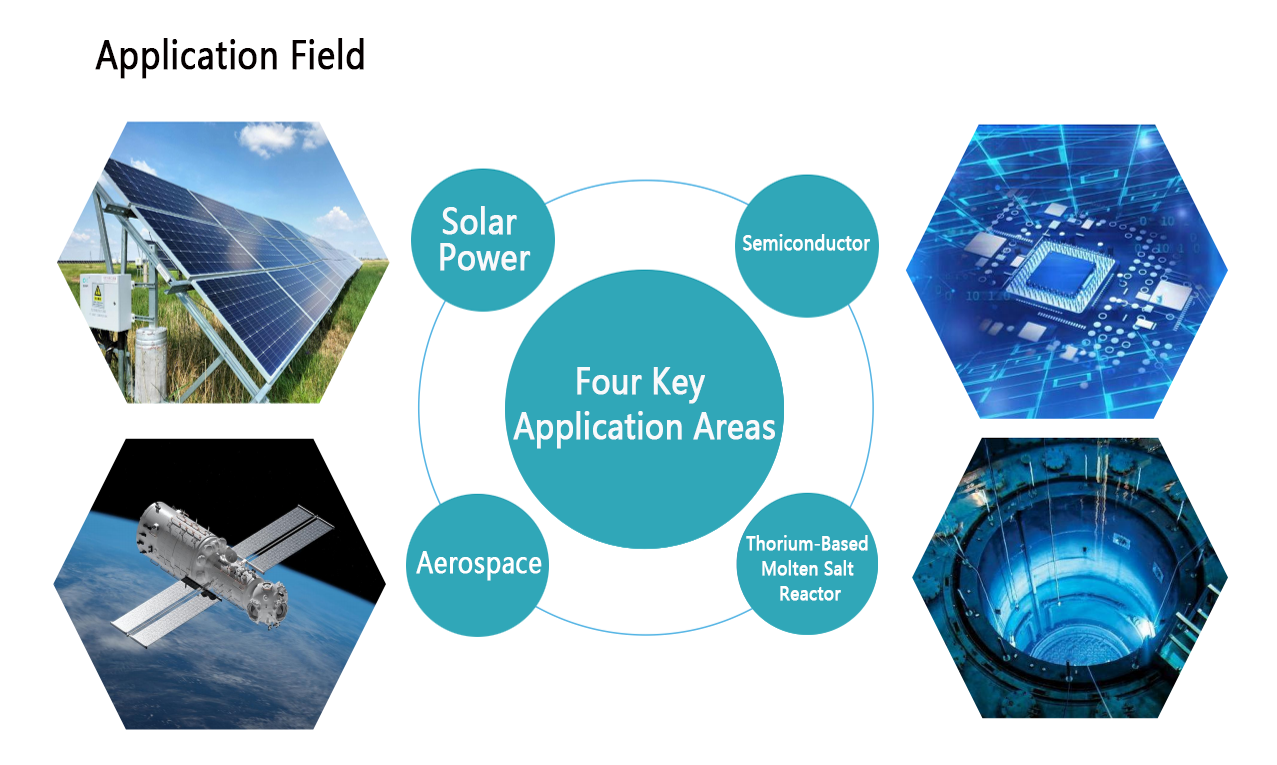

Cov ntaub ntawv tseem ceeb rau kev lag luam niaj hnub

1. Kev lag luam semiconductor

2. Kev lag luam hnub ci zog

3. Aerospace kev lag luam

4. Kev lag luam nuclear

Semicera isostatic pressed graphite project, tau dhau los ntawm kev tsim khoom loj kom tau txais qhov siab ceev, siab purity, siab zog, loj loj graphite khoom

High-zoo los 1st; kev txhawb nqa yog qhov tseem ceeb; kev lag luam yog kev koom tes "yog peb lub tswv yim ua lag luam me uas tau ua haujlwm tsis tu ncua thiab ua raws los ntawm peb lub koom haum rau OEM / ODM Cov Khoom Siv Yooj Yim Txhim Kho Sic Heating Elements rau Cov Hluav Taws Xob Hluav Taws Xob, Peb tau tshawb nrhiav ua ntej los tsim kev sib txuas zoo thiab muaj txiaj ntsig nrog txhua tus neeg muab kev pabcuam hauv lub ntiaj chaw. Peb zoo siab tos txais koj los tham nrog peb kom pib sib tham txog yuav ua li cas peb tuaj yeem coj qhov no los ua.

OEM / ODM tus neeg muag khoomTuam Tshoj Heating Element thiab Sic Heating Elements, Peb lees paub rau pej xeem, kev koom tes, yeej-yeej qhov xwm txheej raws li peb lub hauv paus ntsiab lus, ua raws li lub tswv yim ntawm kev ua neej zoo, ua kom muaj kev ncaj ncees, ua siab dawb cia siab tias yuav tsim kom muaj kev sib raug zoo nrog ntau thiab ntau tus neeg siv khoom thiab cov phooj ywg, kom ua tiav qhov xwm txheej yeej-yeej thiab kev vam meej.

-

Tuam Tshoj OEM Kub Muag Thaum tshav kub kub Resistance Clear Fused C ...

-

Kev cob qha Hoobkas rau Tuam Tshoj Supplier Silicon ...

-

OEM Hoobkas rau Customizable High Temperature a ...

-

OEM Customized U Sic rhaub, Sic Cua sov Elemen ...

-

Tus nqi pheej yig Hoobkas Nqe Custom Industrial Cer ...

-

Competitive Nqe rau Refractory Nozzles Materi ...