SiC ceramic rollers muaj kev hnav zoo heev thiab tuaj yeem tiv taus siab thiab kev sib txhuam yam tsis poob qhov zoo. Nws qhov hardness yog ze rau ntawm pob zeb diamond, uas ua rau nws txo qis kev sib cuag nrog cov ntaub ntawv hlau thiab txuas ntxiv lub neej kev pab cuam ntawm cov menyuam. Kev sib txhuam qis coefficient ntawm SiC ceramic rollers kuj txo lub zog poob thiab tsim hluav taws xob, txhim kho kev tsim khoom.

Tsis tas li ntawd, SiC ceramic rollers muaj qhov kub thiab txias tsis kam. Nws tuaj yeem ua haujlwm ruaj khov hauv qhov kub thiab txias yam tsis muaj softening lossis deformation. Qhov no ua rau SiC ceramic rollers haum rau cov txheej txheem kub kub xws li hlau kub dov thiab nruam casting, kom ntseeg tau tias cov chais muaj kev ua tau zoo thiab qhov ruaj khov nyob rau hauv qhov kub thiab txias.

SiC ceramic rollers kuj muaj kev tiv thaiv corrosion zoo heev. Nws tuaj yeem tiv thaiv kev yaig ntawm cov tshuaj xws li cov kua qaub, alkalis, cov kuab tshuaj thiab cov roj corrosive, tswj qhov chaw tiav thiab kev ua haujlwm ntawm cov menyuam. Qhov no ua rau SiC ceramic rollers ua tau zoo hauv cov ntawv thov xws li kev ua tshuaj lom neeg thiab electroplating, ncua kev pab cuam lub neej ntawm cov khoom siv thiab txhim kho cov khoom zoo.

Cov yam ntxwv ntawm SiC ceramic rollers muab lawv zoo heev inertial yam ntxwv thiab kev co txo qhov muaj peev xwm, yog li txo kev vibration thiab suab nrov, txhim kho cov khoom ruaj khov thiab kev ua haujlwm zoo. Nws qhov ntev thiab lub tiaj tiaj ua kom cov menyuam ruaj khov thiab du, muab cov txiaj ntsig zoo rau kev ua haujlwm hlau thiab luam ntawv.

Tsis-siab sintered silicon carbide cov menyuam, atmospheric siab sintered silicon carbide ceramic khoom, siv high purity ultra-fine silicon carbide hmoov, sintered ntawm 2450 ℃ siab kub, silicon carbide cov ntsiab lus ntawm ntau tshaj 99.1%, cov khoom ntom ≥3.10g / cm3, tsis muaj hlau impurities xws li hlau silicon.

► Silicon carbide cov ntsiab lus --≥99%;

► Kub kub kuj - ib txwm siv ntawm 1800 ℃;

► High thermal conductivity - piv rau thermal conductivity ntawm graphite cov ntaub ntawv;

► High hardness - hardness thib ob tsuas yog pob zeb diamond, cubic boron nitride;

► Corrosion kuj - muaj zog acid thiab alkali tsis muaj corrosion, corrosion kuj zoo dua tungsten carbide thiab alumina;

► Lub teeb yuag - ceev 3.10g / cm3, ze rau txhuas;

► Tsis muaj deformation - me me coefficient ntawm thermal expansion;

► Thermal shock resistance - cov khoom tuaj yeem tiv taus qhov kub thiab txias hloov, thermal shock tsis kam, tiv taus txias thiab kub, kev ua haujlwm ruaj khov.

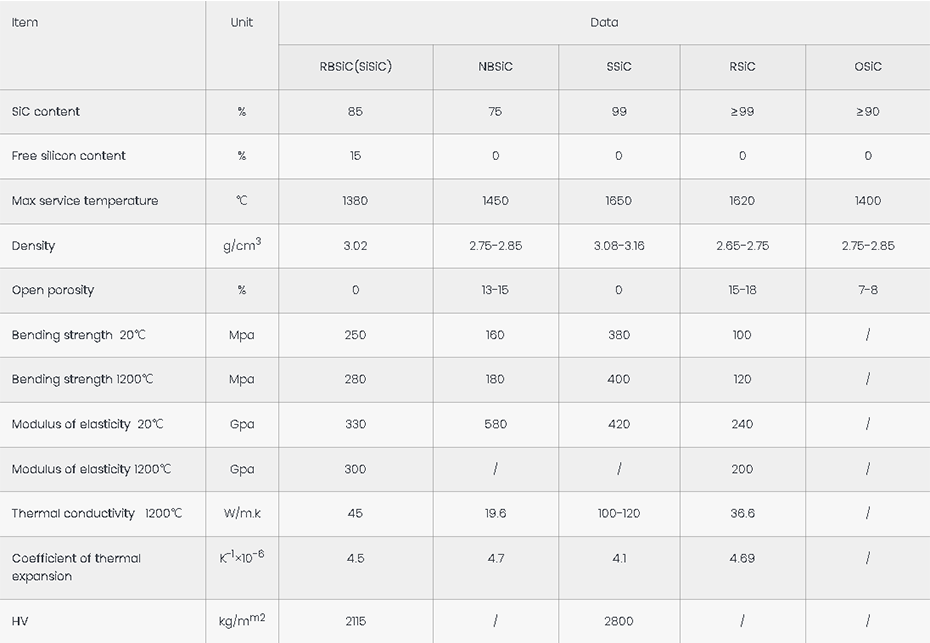

Technical Parameters: