Taw qhia rau CVD TaC Txheej:

CVD TaC Txheej yog ib qho cuab yeej siv tshuaj vapor deposition los tso tantalum carbide (TaC) txheej rau saum npoo ntawm substrate. Tantalum carbide yog cov khoom siv ua haujlwm siab ceramic nrog cov khoom siv zoo heev thiab tshuaj lom neeg. Cov txheej txheem CVD tsim cov yeeb yaj kiab TaC zoo ib yam ntawm cov substrate los ntawm cov tshuaj tiv thaiv roj.

Cov yam ntxwv tseem ceeb:

Zoo heev hardness thiab hnav tsis kam: Tantalum carbide muaj qhov nyuaj siab heev, thiab CVD TaC Txheej tuaj yeem txhim kho qhov hnav tsis kam ntawm lub substrate. Qhov no ua rau cov txheej txheem zoo tagnrho rau kev siv hauv qhov chaw hnav khaub ncaws siab, xws li cov cuab yeej txiav thiab pwm.

Kub kub ruaj khov: TaC coatings tiv thaiv lub cub tawg tseem ceeb thiab cov khoom siv reactor ntawm qhov kub txog li 2200 ° C, ua kom pom kev ruaj ntseg zoo. Nws tswj cov tshuaj thiab cov neeg kho tshuab ruaj khov nyob rau hauv qhov kub thiab txias, ua rau nws tsim nyog rau kev ua haujlwm kub thiab kev siv hauv qhov chaw kub kub.

Zoo heev tshuaj stability: Tantalum carbide muaj zog tiv thaiv corrosion rau feem ntau cov kua qaub thiab alkalis, thiab CVD TaC txheej tuaj yeem tiv thaiv kev puas tsuaj rau cov substrate hauv corrosive ib puag ncig.

Siab melting point: Tantalum carbide muaj qhov siab melting point (kwv yees li 3880 ° C), tso cai rau CVD TaC Txheej siv rau hauv qhov kub thiab txias yam tsis muaj melting lossis degrading.

Zoo heev thermal conductivity: TaC txheej muaj cov thermal conductivity siab, uas yuav pab kom zoo dissipate tshav kub nyob rau hauv high-temperature txheej txheem thiab tiv thaiv lub zos overheating.

Muaj peev xwm siv tau:

• Gallium Nitride (GaN) thiab Silicon Carbide epitaxial CVD reactor Cheebtsam xws li wafer nqa, satellite tais diav, da dej hau, qab nthab, thiab susceptors

• Silicon carbide, gallium nitride thiab txhuas nitride (AlN) siv lead ua kev loj hlob Cheebtsam xws li crucibles, noob tuav, coj rings thiab lim

• Cov khoom lag luam suav nrog cov khoom cua sov tiv thaiv, txhaj tshuaj nozzles, npog rings thiab brazing jigs

Daim ntawv thov nta:

• Kub ruaj khov tshaj 2000 ° C, tso cai rau kev ua haujlwm ntawm qhov kub thiab txias

•Resistant rau hydrogen (Hz), ammonia (NH3), monosilane (SiH4) thiab silicon (Si), muab kev tiv thaiv nyob rau hauv ib puag ncig hnyav tshuaj

• Nws cov thermal shock tsis kam ua kom muaj kev ua haujlwm nrawm dua

• Graphite muaj zog adhesion, ua kom lub neej ua haujlwm ntev thiab tsis muaj txheej txheej delamination.

• Ultra-siab purity tshem tawm cov impurities uas tsis tsim nyog los yog cov kab mob

• Conformal txheej tiv thaiv kom nruj me ntsis kam rau ua

Technical specifications:

Kev npaj ntom ntom tantalum carbide txheej los ntawm CVD:

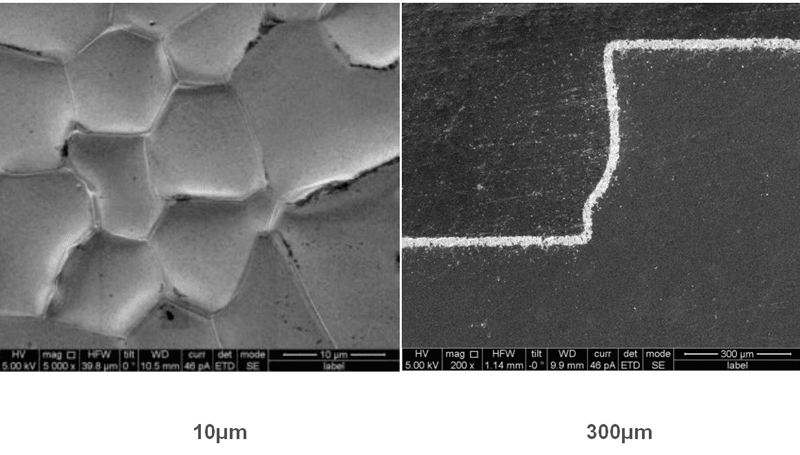

TAC txheej nrog siab crystallinity thiab zoo heev uniformity:

CVD TAC COATING Technical Parameters_Semicera:

| Lub cev muaj zog ntawm TaC txheej | |

| Qhov ntom | 14.3 (g / cm³) |

| Tej Concentration | 8 x1015/cm |

| Tshwj xeeb emissivity | 0.3 |

| Thermal expansion coefficient | 6.3 10-6/K |

| Hardness (HK) | 2000 HK |

| Tej Resistivity | 4.5cm ua |

| Kev tiv thaiv | 1 x10-5Aw* cm |

| Thermal stability | <2500 ℃ |

| Mobility | 2 37cm2/Vs |

| Graphite loj hloov | -10 ~ 20 hli |

| Txheej thickness | ≥20um tus nqi raug (35um + 10um) |

Cov saum toj no yog cov nqi ib txwm.