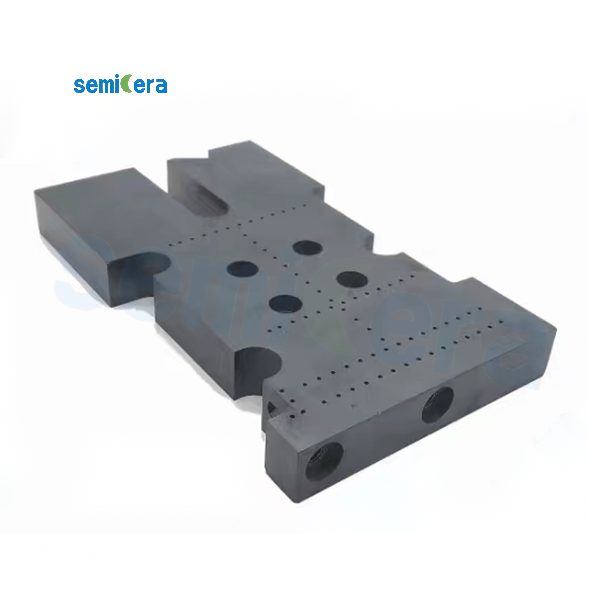

Qhov zoo

Kub kub oxidation tsis kam

Zoo heev Corrosion kuj

Zoo Abrasion tsis kam

High coefficient ntawm tshav kub conductivity

Self-lubricity, tsawg ntom

Siab hardness

Customized tsim.

Daim ntawv thov

-Kev hnav-tiv taus teb: bushing, phaj, sandblasting nozzle, cyclone hauv ob sab phlu, sib tsoo chim, thiab lwm yam ...

-High Temperature: siC Slab, Quenching Rauv Tube, Radiant Tube, crucible, Cua sov Cheebtsam, Roller, Beam, Thaum tshav kub kub Exchanger, Cua txias yeeb nkab, Burner Nozzle, Thermocouple Protection Tube, SiC nkoj, Kiln tsheb Structure, Setter, thiab lwm yam.

-Silicon Carbide Semiconductor: SiC wafer nkoj, sic chuck, sic paddle, sic cassette, sic diffusion raj, wafer diav rawg, suction phaj, guideway, thiab lwm yam.

-Silicon Carbide Foob Field: txhua yam sealing nplhaib, bearing, bushing, thiab lwm yam.

-Photovoltaic teb: Cantilever Paddle, Sib tsoo chim, Silicon Carbide Roller, thiab lwm yam.

- Lithium roj teeb teb

Physical Properties Of SiC

| Khoom | Tus nqi | Txoj kev |

| Qhov ntom | 3.21 g / cc | Sink-float thiab dimension |

| Tshwj xeeb kub | 0.66 J / g ° K | Pulsed laser flash |

| Flexural zog | 450 MPa 560 MPa | 4 taw tes khoov, RT4 taw tes khoov, 1300 ° |

| Fracture toughness | 2.94 MPa m1/2 | Microindentation |

| Hardness | 2800 | Vicker's, 500g load |

| Elastic ModulusYoung's Modulus | 450 GPa 430 GPa | 4 pt khoov, RT4 pt khoov, 1300 ° C |

| Cov qoob loo loj | 2-10 µm | SEM |

Thermal Properties ntawm SiC

| Thermal conductivity | 250 W / m ° K | Laser flash method, RT |

| Thermal Expansion (CTE) | 4.5 x 10-6 ° K | Chav ntsuas kub txog 950 ° C, silica dilatometer |

Technical Parameters

| Yam khoom | Chav tsev | Cov ntaub ntawv | ||||

| RBSiC (SiSiC) | NBSiC | SIB | RSiC | OSiC | ||

| SiC cov ntsiab lus | % | 85 | 75 | 99 | 99.9 ua | ≥99 |

| Dawb silicon ntsiab lus | % | 15 | 0 | 0 | 0 | 0 |

| Max kev pab kub | ℃ | 1380 | 1450 | 1650 | 1620 | 1400 |

| Qhov ntom | g/cm3 | 3.02 Nws | 2.75-2.85 Nws | 3.08-3.16 Nws | 2.65-2.75 Nws | 2.75-2.85 Nws |

| Qhib porosity | % | 0 | 13-15 | 0 | 15-18 | 7–8 |

| Bending zog 20 ℃ | Mpa | 250 | 160 | 380 | 100 | / |

| Bending zog 1200 ℃ | Mpa | 280 | 180 | 400 | 120 | / |

| Modulus ntawm elasticity 20 ℃ | Gpa | 330 | 580 | 420 | 240 | / |

| Modulus ntawm elasticity 1200 ℃ | Gpa | 300 | / | / | 200 | / |

| Thermal conductivity 1200 ℃ | W/mK | 45 | 19.6 ib | 100-120 | 36.6 ib | / |

| Coefficient ntawm thermal expansion | K-1X 10-6 | 4.5 | 4.7 | 4.1 | 4.69 ib | / |

| HV | Kg / mm2 | 2115 | / | 2800 | / | / |

CVD silicon carbide txheej rau sab nrauv ntawm recrystallized silicon carbide ceramic khoom tuaj yeem ncav cuag qhov purity ntau dua 99.9999% kom tau raws li qhov xav tau ntawm cov neeg siv khoom hauv kev lag luam semiconductor.