MEMS Processing - Bonding: Daim Ntawv Thov thiab Kev Ua Haujlwm hauv Kev Lag Luam Semiconductor, Semicera Customized Service

Hauv kev lag luam microelectronics thiab semiconductor, MEMS (micro-electromechanical systems) thev naus laus zis tau dhau los ua ib qho ntawm cov thev naus laus zis tseem ceeb uas tsav kev tsim kho tshiab thiab cov cuab yeej ua haujlwm siab. Nrog rau kev nce qib ntawm kev tshawb fawb thiab thev naus laus zis, MEMS thev naus laus zis tau siv dav hauv sensors, actuators, optical devices, khoom siv kho mob, automotive electronics thiab lwm yam kev lag luam, thiab tau maj mam dhau los ua ib feem tseem ceeb ntawm cov cuab yeej siv niaj hnub no. Hauv cov teb no, cov txheej txheem kev sib txuas (Bonding), uas yog cov kauj ruam tseem ceeb hauv kev ua MEMS, ua lub luag haujlwm tseem ceeb hauv kev ua haujlwm thiab kev ntseeg siab ntawm lub cuab yeej.

Bonding yog ib qho cuab yeej uas ruaj khov ua ke ob lossis ntau cov ntaub ntawv los ntawm lub cev lossis tshuaj. Feem ntau, cov txheej txheem sib txawv yuav tsum tau txuas nrog kev sib txuas hauv MEMS cov cuab yeej kom ua tiav cov qauv kev ntseeg siab thiab kev ua haujlwm tau zoo. Hauv kev tsim cov txheej txheem ntawm MEMS cov cuab yeej, kev sib txuas tsis yog tsuas yog cov txheej txheem sib txuas, tab sis tseem cuam tshuam ncaj qha rau thermal stability, mechanical zog, hluav taws xob kev ua tau zoo thiab lwm yam ntawm cov cuab yeej.

Nyob rau hauv high-precision MEMS ua, cov cuab yeej sib txuas yuav tsum tau ua kom muaj kev sib raug zoo ntawm cov ntaub ntawv thaum tsis txhob muaj qhov tsis xws luag uas cuam tshuam rau kev ua haujlwm ntawm lub cuab yeej. Yog li ntawd, kev tswj xyuas meej ntawm cov txheej txheem kev sib txuas thiab cov khoom sib txuas zoo yog qhov tseem ceeb los xyuas kom meej tias cov khoom kawg ua tau raws li cov qauv kev lag luam.

MEMS daim ntawv cog lus hauv kev lag luam semiconductor

Hauv kev lag luam semiconductor, MEMS thev naus laus zis tau siv dav hauv kev tsim cov khoom siv micro xws li sensors, accelerometers, siab sensors, thiab gyroscopes. Nrog rau qhov kev thov nce ntxiv rau cov khoom siv me me, kev sib xyaw ua ke, thiab cov khoom ntse, qhov tseeb thiab kev ua tau zoo ntawm MEMS cov khoom siv kuj tseem nce ntxiv. Hauv cov ntawv thov no, kev sib txuas tshuab yog siv los txuas cov khoom sib txawv xws li silicon wafers, iav, hlau, thiab polymers kom ua tiav cov haujlwm zoo thiab ruaj khov.

1. Siab sensors thiab accelerometers

Hauv kev lag luam tsheb, aerospace, cov khoom siv hluav taws xob, thiab lwm yam, MEMS siab sensors thiab accelerometers tau siv dav hauv kev ntsuas thiab tswj cov tshuab. Cov txheej txheem kev sib txuas yog siv los txuas cov chips silicon thiab cov ntsiab lus sensor kom ntseeg tau siab thiab raug. Cov sensors no yuav tsum muaj peev xwm tiv taus ib puag ncig huab cua, thiab cov txheej txheem kev sib txuas zoo tuaj yeem tiv thaiv cov ntaub ntawv los ntawm kev sib cais lossis ua haujlwm tsis zoo vim qhov kub hloov pauv.

2. Micro-optical li thiab MEMS optical keyboards

Hauv kev sib txuas lus kho qhov muag thiab cov khoom siv laser, MEMS optical devices thiab optical keyboards ua lub luag haujlwm tseem ceeb. Bonding tshuab yog siv los ua kom tiav kev sib txuas ntawm silicon-based MEMS cov khoom siv thiab cov ntaub ntawv xws li fiber ntau thiab iav kom paub meej tias qhov ua tau zoo thiab ruaj khov ntawm cov teeb liab kis tau tus mob. Tshwj xeeb tshaj yog nyob rau hauv daim ntawv thov nrog high zaus, dav bandwidth thiab ntev-kev kis tau tus mob, high-kev ua tau zoo bonding tshuab yog ib qho tseem ceeb heev.

3. MEMS gyroscopes thiab inertial sensors

MEMS gyroscopes thiab inertial sensors yog dav siv rau cov kev taw qhia meej thiab qhov chaw nyob rau hauv high-end industries xws li kev tsav tsheb, neeg hlau, thiab aerospace. Cov txheej txheem kev sib raug zoo siab tuaj yeem ua kom ntseeg tau ntawm cov khoom siv thiab zam kev ua haujlwm tsis zoo lossis tsis ua haujlwm thaum lub sijhawm ua haujlwm ntev lossis ua haujlwm siab.

Cov kev xav tau tseem ceeb ntawm kev sib koom tes thev naus laus zis hauv MEMS ua

Hauv MEMS ua, qhov zoo ntawm cov txheej txheem sib txuas ncaj qha txiav txim siab qhov ua tau zoo, lub neej thiab kev ruaj ntseg ntawm lub cuab yeej. Txhawm rau kom ntseeg tau tias MEMS cov cuab yeej tuaj yeem ua haujlwm tau ntev ntev hauv ntau qhov xwm txheej, kev sib txuas tshuab yuav tsum muaj cov haujlwm tseem ceeb hauv qab no:

1. Siab thermal stability

Ntau daim ntawv thov ib puag ncig hauv kev lag luam semiconductor muaj qhov kub thiab txias, tshwj xeeb tshaj yog nyob rau hauv kev lag luam tsheb, aerospace, thiab lwm yam. Lub thermal stability ntawm cov khoom sib txuas yog qhov tseem ceeb thiab tuaj yeem tiv taus qhov kub thiab txias yam tsis muaj degradation lossis tsis ua haujlwm.

2. Siab hnav tsis kam

MEMS cov cuab yeej feem ntau koom nrog cov txheej txheem micro-mechanical, thiab kev sib txhuam mus sij hawm ntev thiab kev txav mus los yuav ua rau hnav ntawm cov khoom sib txuas. Cov khoom siv sib txuas yuav tsum muaj kev hnav zoo heev kom ntseeg tau tias kev ruaj ntseg thiab kev ua haujlwm ntawm cov cuab yeej siv tau ntev.

3. High purity

Kev lag luam semiconductor muaj cov cai nruj heev ntawm cov khoom siv purity. Txhua yam kab mob me me tuaj yeem ua rau lub cuab yeej tsis ua haujlwm lossis kev ua haujlwm tsis zoo. Yog li ntawd, cov ntaub ntawv siv nyob rau hauv cov txheej txheem kev sib txuas yuav tsum muaj siab purity siab heev los xyuas kom meej tias cov cuab yeej tsis cuam tshuam los ntawm kev sib kis sab nraud thaum lub sijhawm ua haujlwm.

4. Kev sib raug zoo ntawm kev sib raug zoo

MEMS cov khoom siv feem ntau xav tau micron-theem lossis txawm nanometer-theem ua qhov raug. Cov txheej txheem kev sib txuas yuav tsum xyuas kom meej qhov sib dhos ntawm txhua txheej ntawm cov khoom siv kom ntseeg tau tias kev ua haujlwm thiab kev ua haujlwm ntawm cov cuab yeej tsis cuam tshuam.

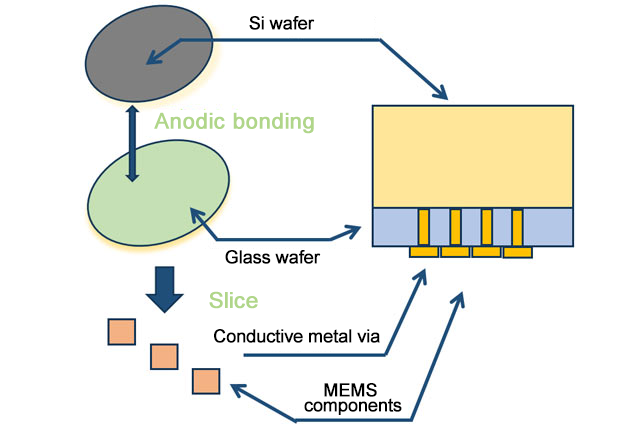

Anodic sib txuas

Anodic sib txuas:

● Muaj feem xyuam rau kev sib txuas ntawm silicon wafers thiab iav, hlau thiab iav, semiconductor thiab alloy, thiab semiconductor thiab iav

Eutectoid sib txuas:

● Muaj feem xyuam rau cov ntaub ntawv xws li PbSn, AuSn, CuSn, thiab AuSi

Glue bonding:

● Siv cov kua nplaum tshwj xeeb, tsim rau cov kua nplaum tshwj xeeb xws li AZ4620 thiab SU8

● Muaj feem xyuam rau 4-nti thiab 6-nti

Semicera Custom Bonding Service

Raws li kev lag luam ua lag luam ntawm MEMS cov kev daws teeb meem, Semicera tau cog lus los muab cov neeg siv khoom nrog kev ua haujlwm siab, kev ruaj khov kho kev sib koom ua ke. Peb cov cuab yeej sib txuas tuaj yeem siv dav hauv kev sib txuas ntawm cov khoom sib txawv, suav nrog silicon, iav, hlau, ceramics, thiab lwm yam, muab cov kev daws teeb meem tshiab rau kev siv high-end hauv semiconductor thiab MEMS teb.

Semicera muaj cov cuab yeej tsim khoom thiab pab pawg ua haujlwm, thiab tuaj yeem muab cov kev pabcuam kev sib koom ua ke raws li cov kev xav tau tshwj xeeb ntawm cov neeg siv khoom. Txawm hais tias nws yog kev sib txuas txhim khu kev qha nyob rau hauv qhov kub thiab txias ib puag ncig, los yog kev sib txuas ntawm micro-device, Semicera tuaj yeem ua tau raws li ntau yam kev xav tau los xyuas kom meej tias txhua yam khoom tuaj yeem ua tau raws li cov qauv zoo tshaj plaws.

Peb cov kev pabcuam kev sib koom ua ke tsis txwv rau cov txheej txheem sib txuas ua ke, tab sis kuj suav nrog kev sib txuas hlau, thermal compression bonding, nplaum nplaum thiab lwm yam txheej txheem, uas tuaj yeem muab kev pabcuam kev pabcuam rau cov khoom sib txawv, cov qauv thiab cov ntawv thov. Tsis tas li ntawd, Semicera kuj tseem tuaj yeem muab cov neeg siv khoom nrog kev pabcuam tag nrho los ntawm kev tsim qauv rau kev tsim khoom loj los xyuas kom meej tias txhua qhov kev xav tau ntawm cov neeg siv khoom tuaj yeem ua tiav.