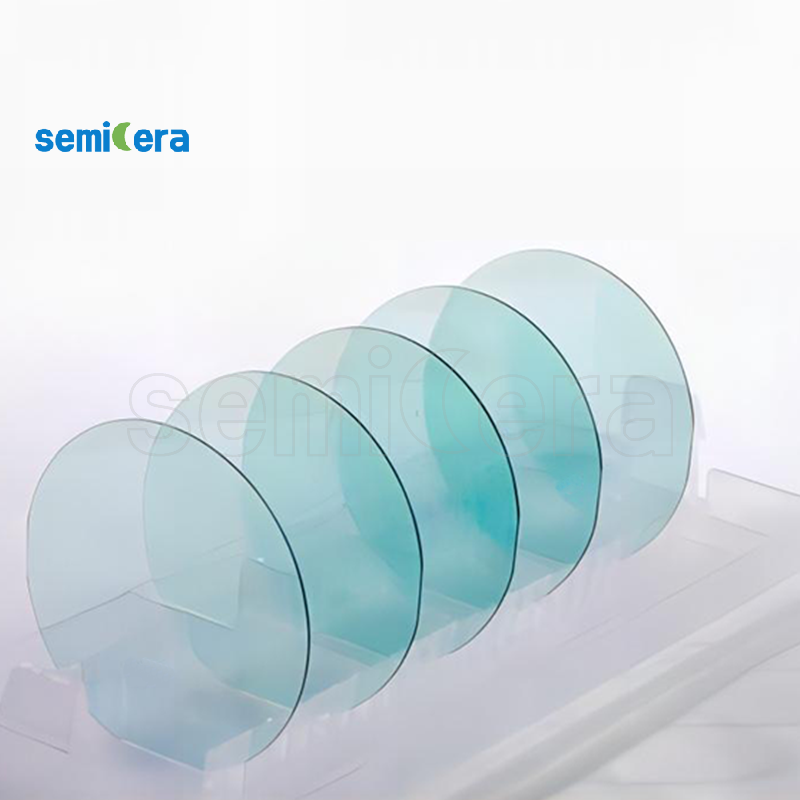

Semicera nthuav tawm cov kev cai zoosilicon carbide cantilever paddlescrafted los txhawb cov txheej txheem tsim khoom semiconductor. Lub tswv yim tshiabSiC paddletsim kom ntseeg tau tshwj xeeb durability thiab siab thermal kuj, ua rau nws yog ib qho tseem ceeb tivthaiv rau wafer tuav nyob rau hauv nyuaj high-temperature ib puag ncig.

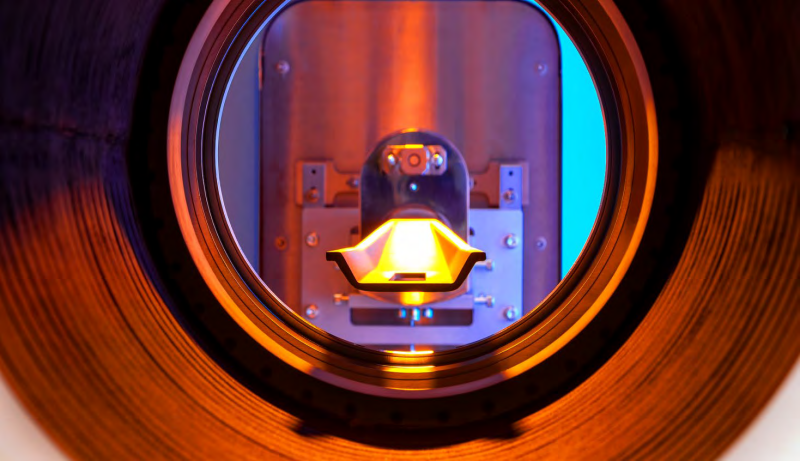

CovSilicon carbide paddleyog tsim los tiv thaiv lub voj voog huab cua thaum tswj kev ua haujlwm zoo, kom ntseeg tau tias kev thauj mus los ntawm wafer txhim khu kev qha thaum lub sijhawm tseem ceeb ntawm cov khoom siv semiconductor. Nrog superior mechanical zog, qhov nonkoj waferminimizes qhov kev pheej hmoo ntawm kev puas tsuaj rau wafers, ua rau ntau dua yields thiab zoo ib yam ntau lawm.

Ib qho ntawm cov kev hloov tshiab tseem ceeb hauv Semicera's SiC paddle nyob hauv nws cov kev cai tsim kev xaiv. Ua kom tau raws li cov kev xav tau tshwj xeeb, lub paddle muaj qhov yooj yim hauv kev koom ua ke nrog ntau yam khoom siv, ua rau nws yog qhov kev daws teeb meem zoo tshaj plaws rau cov txheej txheem niaj hnub fabrication. Lub teeb yuag tab sis muaj zog kev tsim kho ua kom yooj yim tuav thiab txo qis kev ua haujlwm, pab txhawb kev txhim kho hauv kev tsim khoom semiconductor.

Ntxiv rau nws cov thermal thiab mechanical zog, lubSilicon carbide paddlemuaj cov tshuaj tiv thaiv zoo heev, ua rau nws ua tau zoo txawm tias nyob rau hauv ib puag ncig hnyav tshuaj. Qhov no ua rau nws tshwj xeeb tshaj yog siv rau hauv cov txheej txheem suav nrog etching, deposition, thiab high-temperature kho, qhov uas tswj kev ncaj ncees ntawm lub nkoj wafer yog qhov tseem ceeb rau kev ua kom cov khoom zoo.

| Lub cev muaj zog ntawm Recrystalized Silicon Carbide | |

| Khoom | Tus nqi |

| Ua haujlwm kub (°C) | 1600 ° C (nrog oxygen), 1700 ° C (txo ib puag ncig) |

| SiC cov ntsiab lus | > 99.96% |

| Dawb Si cov ntsiab lus | <0.1% |

| Qhov ntom ntom | 2.60-2.70 g / cm33 |

| Pom tseeb porosity | <16% |

| Compression zog | > 600 MPa |

| Txias dabtsi yog khoov zog | 80-90 MPa (20 ° C) |

| Kub dabtsi yog khoov zog | 90-100 MPa (1400 ° C) |

| Thermal expansion @ 1500 ° C | 4.70 10-6/°C |

| Thermal conductivity @ 1200 ° C | 23 W/m•K |

| Elastic modulus | 240 GPa |

| Thermal shock resistance | Zoo heev |